Pre-wrapping-pipe-front-mounted composite negative-poisson's-ratio-yarn spinning device and method and application

A technology of negative Poisson's ratio and composite spinning, which is applied in spinning machine, yarn, textile and papermaking, etc., can solve the problem that it is difficult to obtain a higher negative Poisson's ratio, and achieve obvious negative Poisson's ratio effect, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

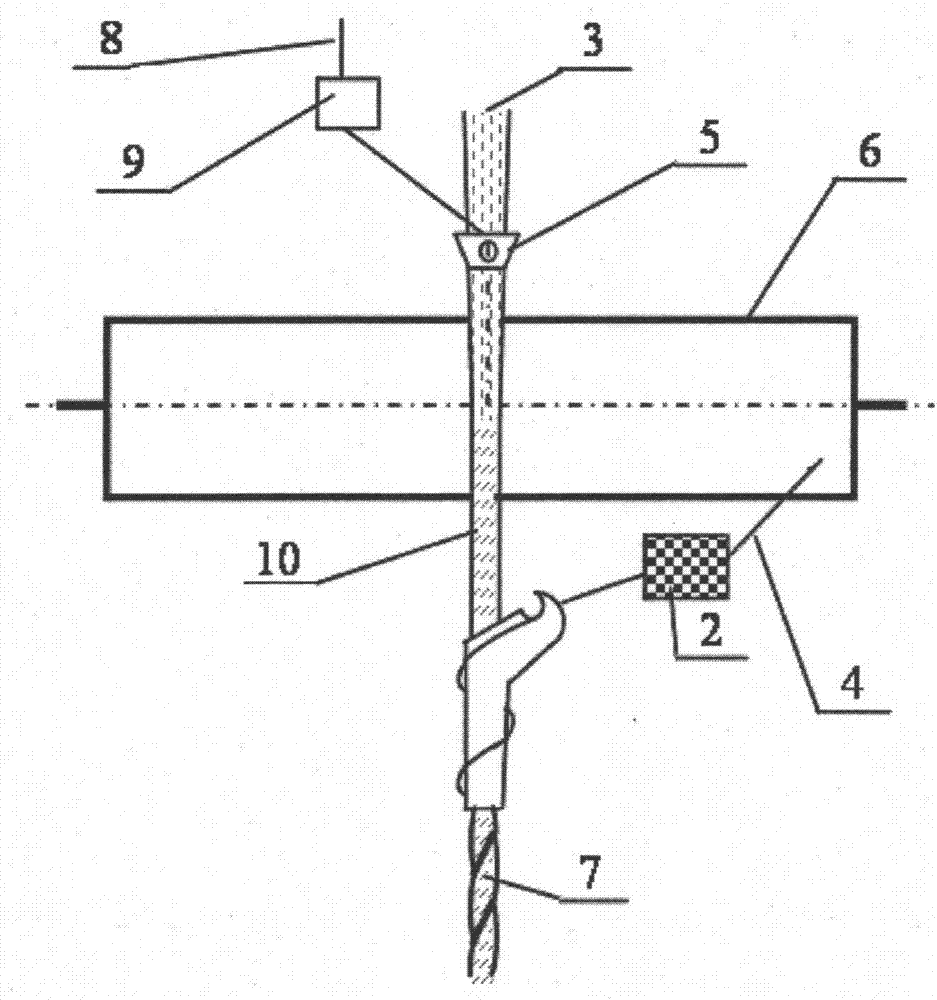

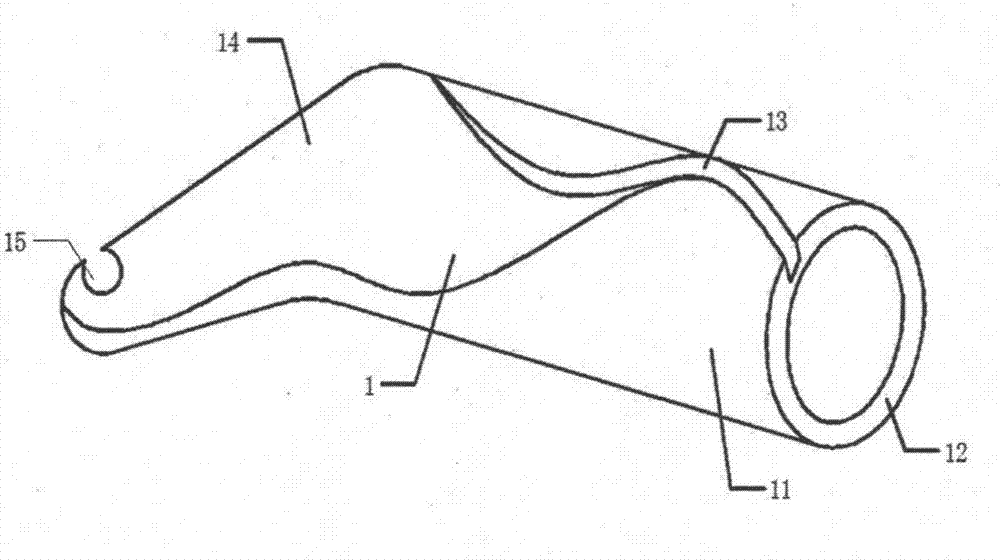

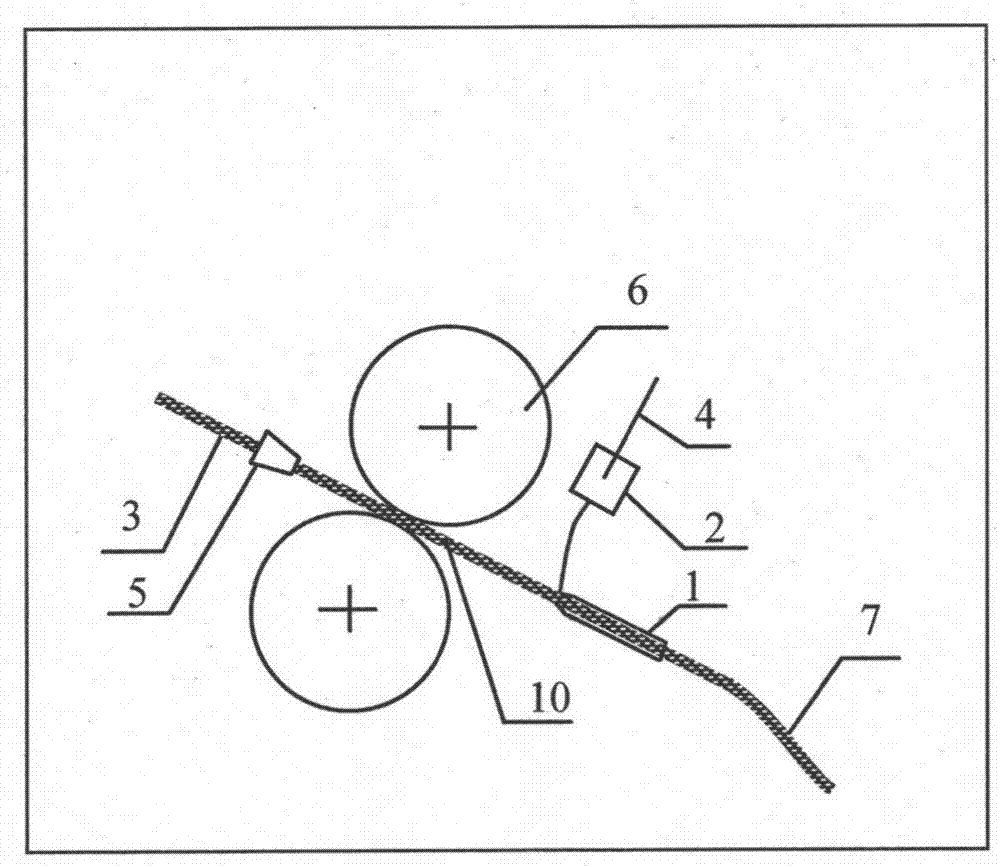

[0061] Embodiment 1: the composite negative Poisson's ratio composite yarn of spinning Nomex staple fiber / Kevlar filament

[0062] Using the above-mentioned pre-wrapping tube composite spinning device of the present invention, the Kevlar filament bundle is fed into the holding roller pair of the overfeed mechanism 2 according to the above-mentioned method, and then the overfeeding enters the pre-wrapping tube 1 and exits the pre-wrapping tube. Yarn port 12 is axially converged with Nomex staple fiber and twisted into yarn. The specific process parameters and measured data of yarn formation are shown in the table. The physical and mechanical property parameters of the Nomex short fiber / Kevlar filament negative Poisson's ratio composite yarn spun are as follows. Wherein, when the Nomex staple fiber / Kevlar filament composite yarn is stretched, the Nomex staple fiber strands change from straightening to spiral wrapping; the Kevlar filament bundles change from spiral wrapping to st...

Embodiment 2

[0063] Example 2: Spinning polyester-cotton staple fiber+elastic yarn / high-strength polyester filament composite negative Poisson's ratio composite yarn

[0064] Using the above-mentioned pre-wrapping tube composite spinning device and process of the present invention, the elastic yarn (spandex) is fed into the holding roller pair of the overfeed mechanism 2 according to the above-mentioned method, and then the overfeeding enters the pre-wrapping tube 1, and the pre-wrapping The bobbin yarn outlet 12 is axially converging with the spun polyester-cotton staple fiber and twisted into yarn. The specific process parameters and yarn-forming measured data are shown in the table. The physical and mechanical property parameters of the spun (polyester-cotton staple fiber+elastic yarn) / high-strength polyester filament negative Poisson's ratio composite yarn are as follows. Among them, when stretching the composite yarn of the elastic core-spun yarn of polyester-cotton staple fiber and s...

Embodiment 3

[0065] Embodiment 3: spinning basalt spun yarn / carbon fiber filament composite negative Poisson's ratio composite yarn

[0066] Using the above-mentioned overfeeding asymmetric two-axis composite spinning device of the present invention, the carbon fiber filament bundle is fed into the holding roller pair of the overfeed mechanism 2 according to the above-mentioned method, and then the overfeed enters the pre-wrapping tube 1 and exits the pre-wrap The bobbin yarn outlet 12 is axially converged and twisted with the spun basalt staple fiber strands to form yarns, and the specific process parameters and yarn-forming measured data are shown in the table. The physical and mechanical performance parameters of the spun basalt staple fiber / carbon fiber filament negative Poisson's ratio composite yarn are as follows. Among them, when the basalt staple fiber / carbon fiber filament composite yarn is stretched, the Wuyan staple fiber strand changes from straightening to spiral wrapping; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com