Halogen-free inflaming-retarding polypropylene composition and preparation method thereof

A flame-retardant polypropylene and composition technology, applied in the field of chemical compositions, can solve problems such as poor compatibility, achieve the effects of improving grafting rate, balancing flame-retardant performance and processing performance, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

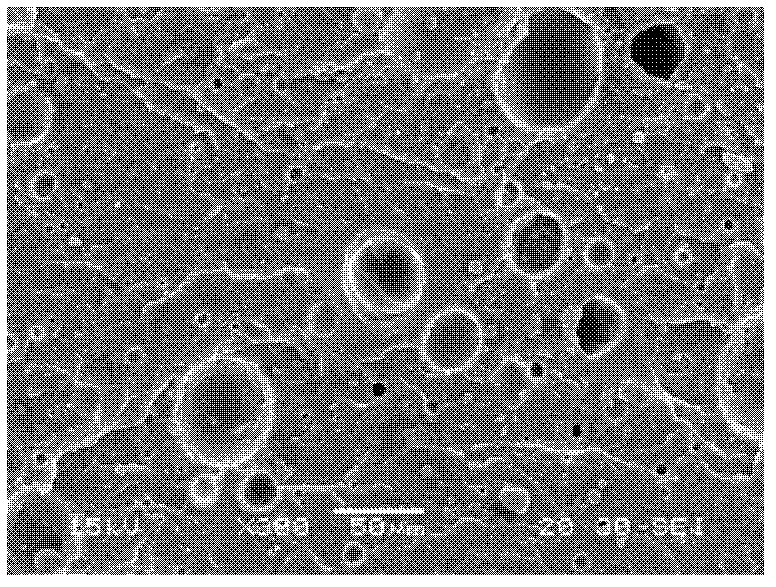

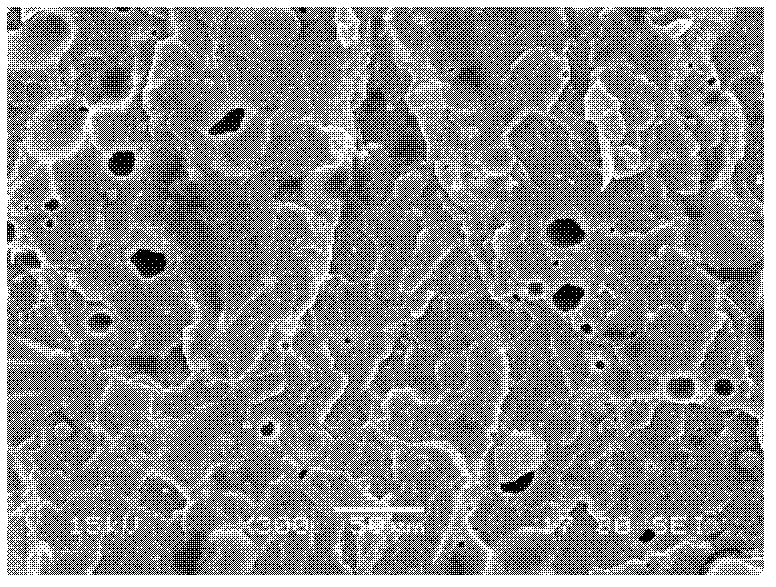

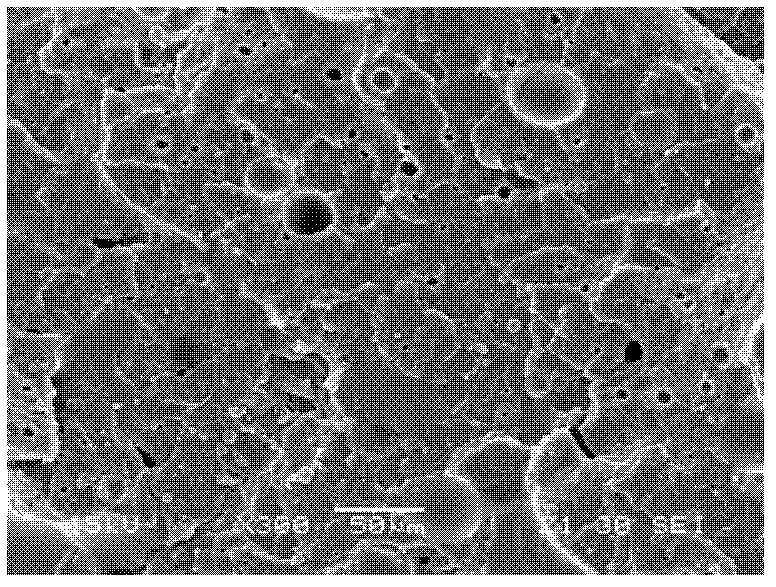

Image

Examples

Embodiment 1-100

[0038] The formula of embodiment 1-100 is as shown in table 1, with a certain amount of polypropylene (F1002B, Yangzi Petrochemical, melt index is 2.83g / 10min) or a certain amount of olefin copolymerized polypropylene, a certain amount of ammonium polyphosphate and pentaerythritol, a certain amount Add a compatibilizer and a certain amount of antioxidant into a high-speed internal mixer, blend for 8 minutes at 180°C and 80r / min, prepare enough blended materials and press them into 3.2mm and 4mm plates at a high temperature press at 180°C, and pass through a sample cutting machine Cut into standard splines for performance testing.

[0039] List the preparation method of part compatibilizer below:

[0040] The preparation method of compatibilizer PP-g-MAH is: a certain amount of polypropylene (Y1600, Shanghai Petrochemical), xylene and maleic anhydride (MAH) are added in a three-necked flask, heated and stirred under nitrogen atmosphere, The temperature rises to 120°C. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com