Direct carbon fuel battery

A fuel cell, direct technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of high implementation temperature, utilization rate of only 33%, low power, etc., and achieve the effect of high performance and huge commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

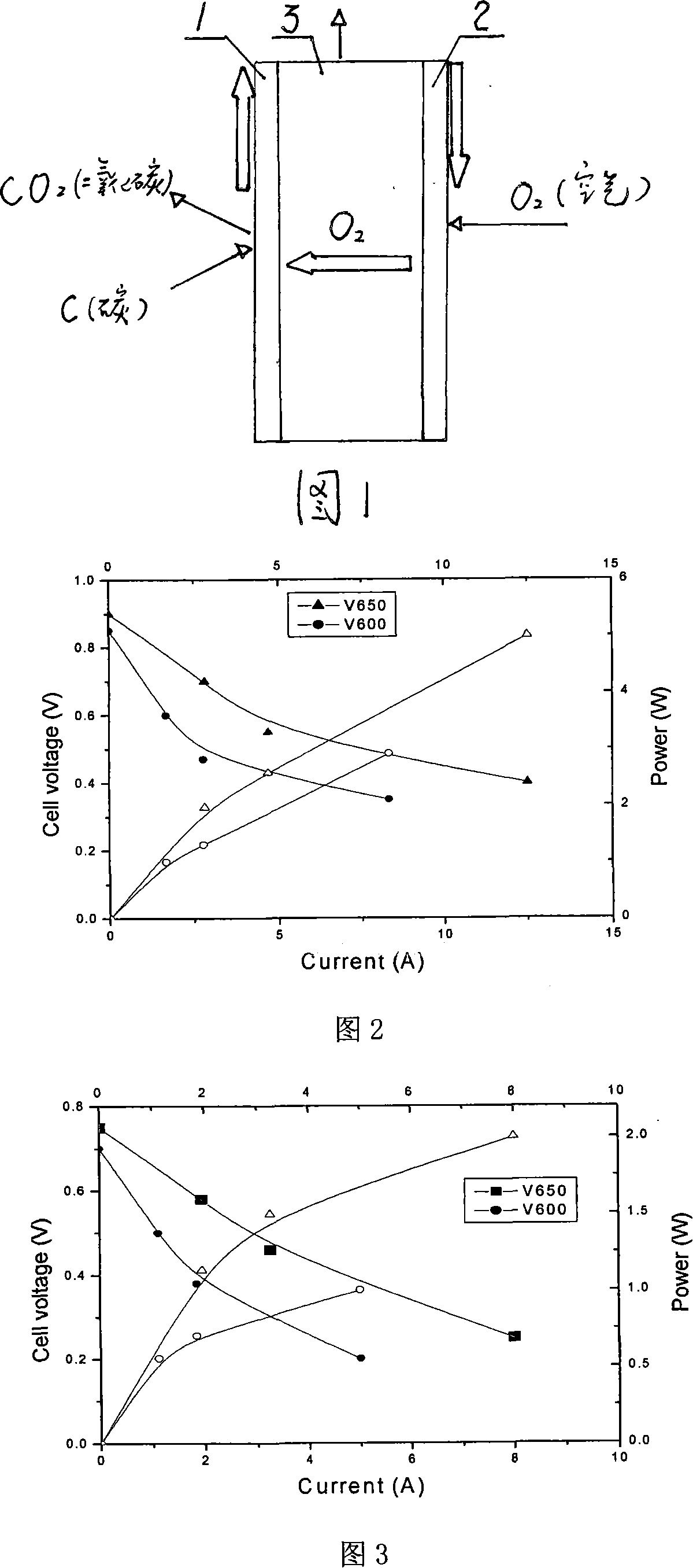

[0023] The direct carbon fuel cell is a powder-molded button cell, the electrolyte 3 is in the middle, and the two sides are the anode 1 and the cathode 2 respectively. mm, the thickness range can be 1-2 mm, see Figure 1.

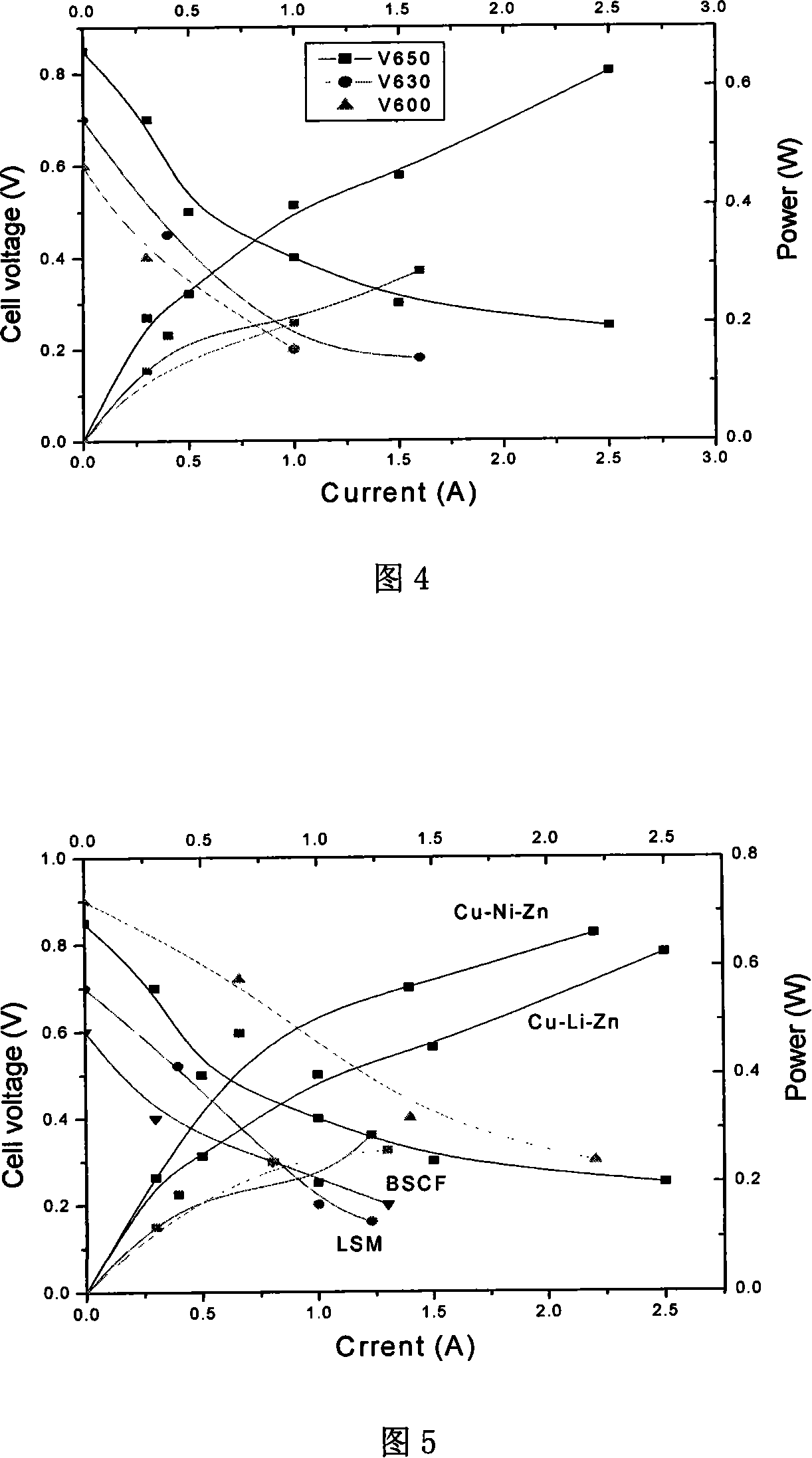

[0024] Examples 1-36 are detailed descriptions of the performance of direct carbon fuel cells in which various carbon materials are used as anodes. See Table 1 for specific anode materials, fuel cell performance, and temperature experimental data.

[0025] (1) The performance of carbon anode material fuel cells (see Table 1), mainly divided into the following categories:

[0026] 1. Performance of biomass-derived direct anode material carbon fuel cells

[0027] 1) Several chemicals activated carbon C: atomic weight: 12.01, analytically pure

[0028] C1 activated carbon (fine granular) Shanghai Sinopharm Chemical Reagent Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com