Integrated device for power generation and energy storage based on liquid metal anode direct carbon fuel cell

A liquid metal and fuel cell technology, used in fuel cell parts, fuel cells, fuel cell additives, etc., can solve the problems of poor electrochemical reaction conditions, low carbon fuel reaction rate, low battery performance, etc. The effect of peaking demand and ensuring power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

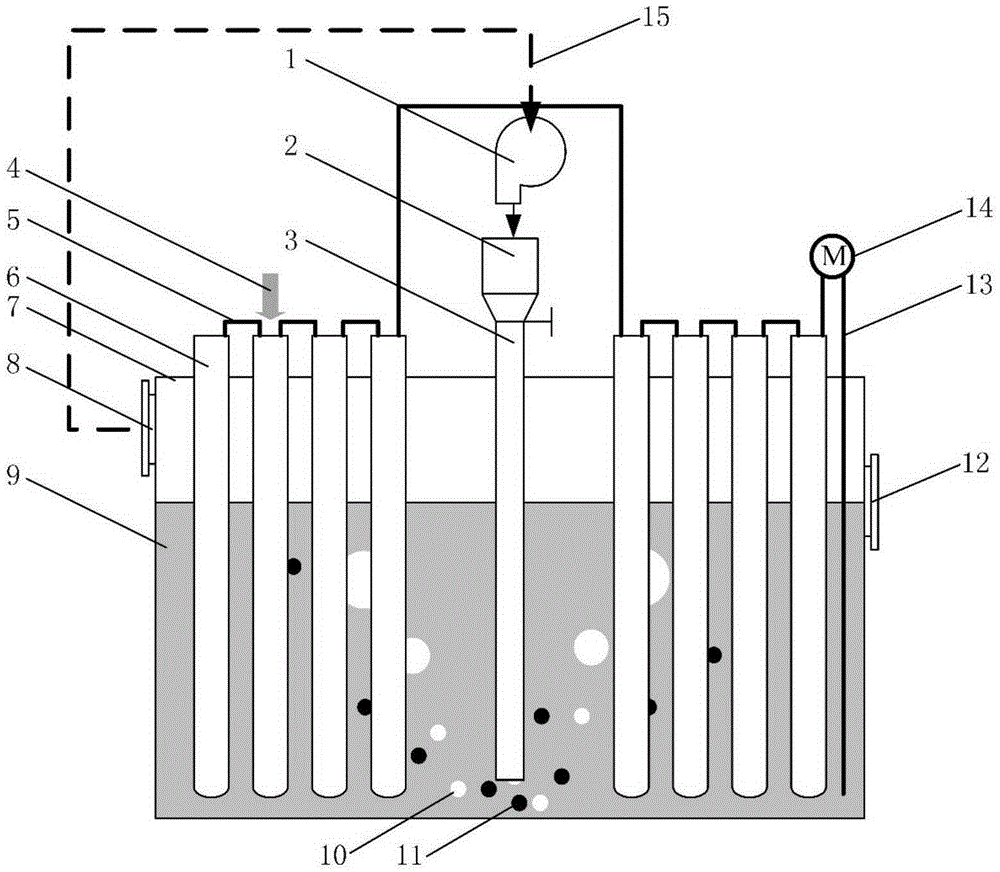

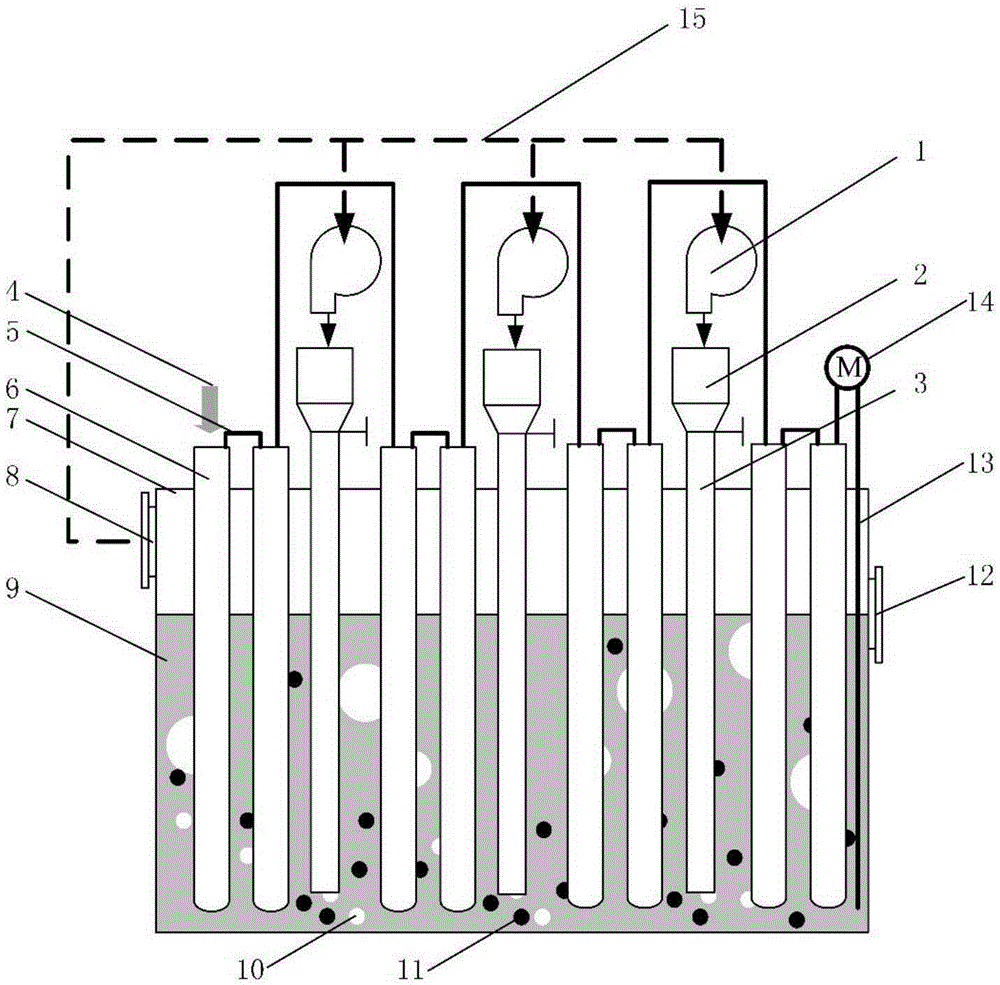

[0040] as attached figure 2 As shown, the power generation and energy storage integrated device based on the liquid metal anode direct carbon fuel cell, the device includes a fluidized air distribution feeding system composed of a feeding blower 1, a material lock hopper 2, and a feeding pipe 3. Solid oxide fuel cell unit 6, metal molten pool shell 7, liquid metal anode 9 and other components. In the actual application process, in order to meet the needs of large-scale equipment for feed volume, air volume and corresponding uniformity requirements, multiple sets of fluidized air distribution feeding systems can be arranged at appropriate positions of the equipment, (the figure shows 3 sets ), its specific quantity and layout position need to be finally determined by comprehensively considering the uniformity of air distribution and feeding materials, system reliability and other issues. Among them, the dead-tube solid oxide fuel cell unit 6 is vertically inserted into the mo...

Embodiment 2

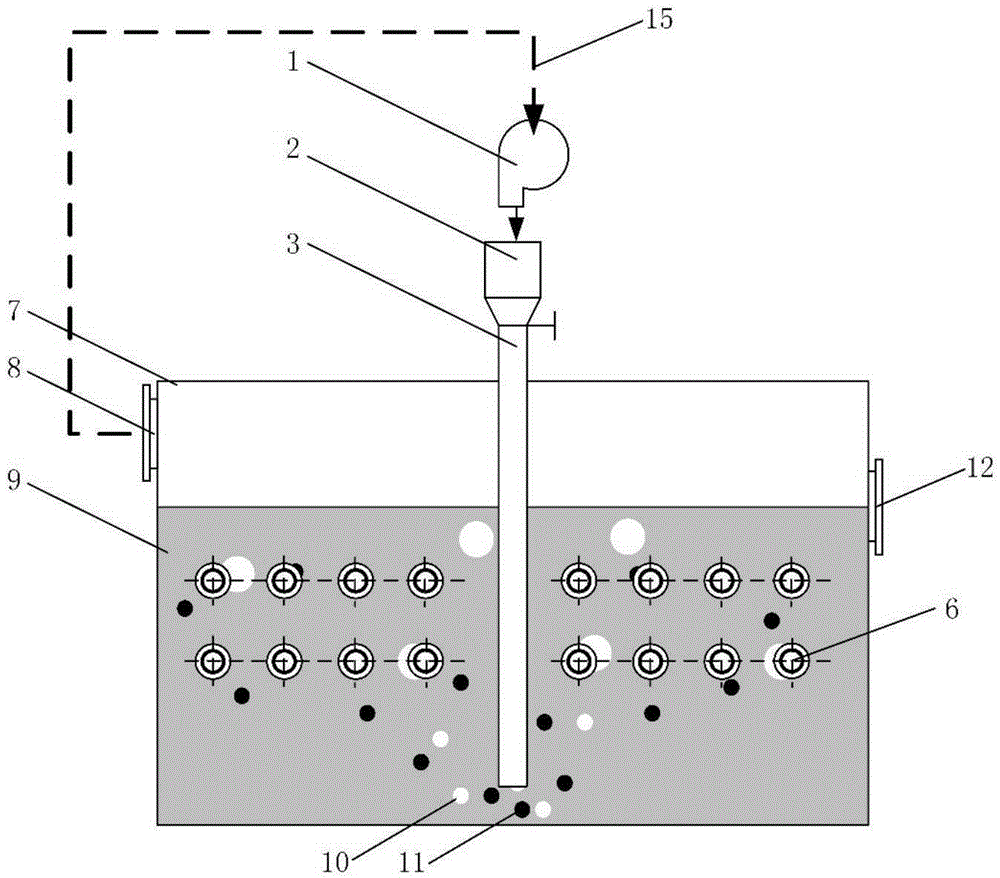

[0042] as attached image 3 , 4 As shown, the power generation and energy storage integrated device based on the liquid metal anode direct carbon fuel cell, the device includes a fluidized air distribution feeding system composed of a feeding blower 1, a material lock hopper 2, and a feeding pipe 3. Solid oxide fuel cell unit 6, metal molten pool shell 7, liquid metal anode 9 and other components. Among them, the dead-tube solid oxide fuel cell unit 6 is horizontally inserted into the molten metal pool from the side of the molten metal pool shell 7 and fixed, its open end is located outside the molten metal pool, and its closed end is located inside the molten metal pool; The solid oxide fuel cell cells 6 can be arranged in an array and stacked, and the gas flow direction in each tube is the same.

Embodiment 3

[0044] as attached Figure 5 As shown, the power generation and energy storage integrated device based on the liquid metal anode direct carbon fuel cell, the device includes a fluidized air distribution feeding system composed of a feeding blower 1, a material lock hopper 2, and a feeding pipe 3. Solid oxide fuel cell unit 6, metal molten pool shell 7, liquid metal anode 9 and other components. Among them, the through-tube solid oxide fuel cell unit 6 is horizontally inserted into the molten metal pool from the side of the molten metal pool shell 7 and fixed, and the open ends on both sides are located outside the molten metal pool; multiple through-tube solid oxide fuel cells The monomers 6 can be arranged in an array, and the gas flow directions in adjacent tubes are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com