Direct carbon fuel cell device with liquid metal tin serving as anode

A liquid metal and fuel cell technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of limiting anode mass transfer efficiency and limited contact area, and achieve the effect of improving anode mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

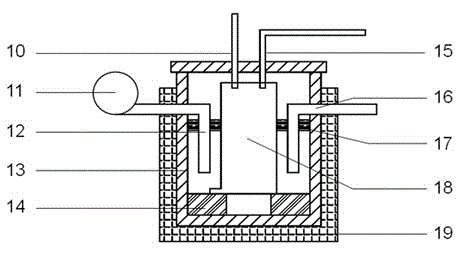

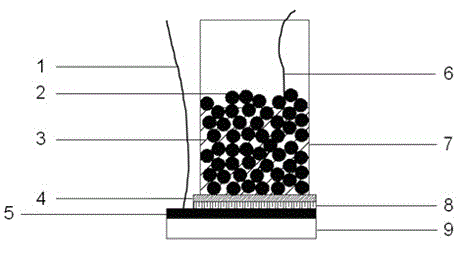

Image

Examples

Embodiment 1

[0029] Example 1: Using carbon black as carbon fuel, mix it with tin powder at a mass ratio of 20:3 and add it into the fuel chamber of a straight carbon fuel cell with liquid metal tin as the anode, and seal the battery device. At normal temperature, nitrogen gas is passed into the anode to remove the air in the anode cavity. Turn on the heater, and when the temperature rises to 500°C, air is introduced into the cathode cavity with an air pressure of 0.5Mpa, and the working conditions of the battery are recorded. The discharge performance of the battery at 750°C is listed here, see attached table 1.

Embodiment 2

[0030] Example 2: Using carbon black as carbon fuel, mix it with tin powder at a mass ratio of 6:1 and add it into the fuel chamber of a direct carbon fuel cell with liquid metal tin as the anode, and seal the battery device. At normal temperature, nitrogen gas is passed into the anode to remove the air in the anode cavity. Turn on the heater, and when the temperature rises to 500°C, air is introduced into the cathode cavity with an air pressure of 0.5Mpa, and the working conditions of the battery are recorded. The discharge performance of the battery at 750°C is listed here, see attached table 1.

Embodiment 3

[0031] Example 3: Using carbon black as carbon fuel, mix it with tin powder at a mass ratio of 11:1 and add it into the fuel chamber of a straight carbon fuel cell with liquid metal tin as the anode, and seal the battery device. At normal temperature, nitrogen gas is passed into the anode to remove the air in the anode cavity. Turn on the heater, and when the temperature rises to 500°C, air is introduced into the cathode cavity with an air pressure of 0.5Mpa, and the working conditions of the battery are recorded. Now list the discharge performance of the battery at 800°C, see attached table 1.

[0032]

[0033] Table 1 is as follows:

[0034] Example Tin: carbon (mass ratio) temperature Maximum current density Maximum Power Density average power density 1 20:3 750 5.37mA / cm 2 4.75mW / cm 2 4.53mW / cm 2 2 6:1 750 9.61mA / cm 2 9.11mW / cm 2 8.64mW / cm 2 3 11:1 800 10.02mA / cm 2 9.90mW / cm 2 8.45mW / cm 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com