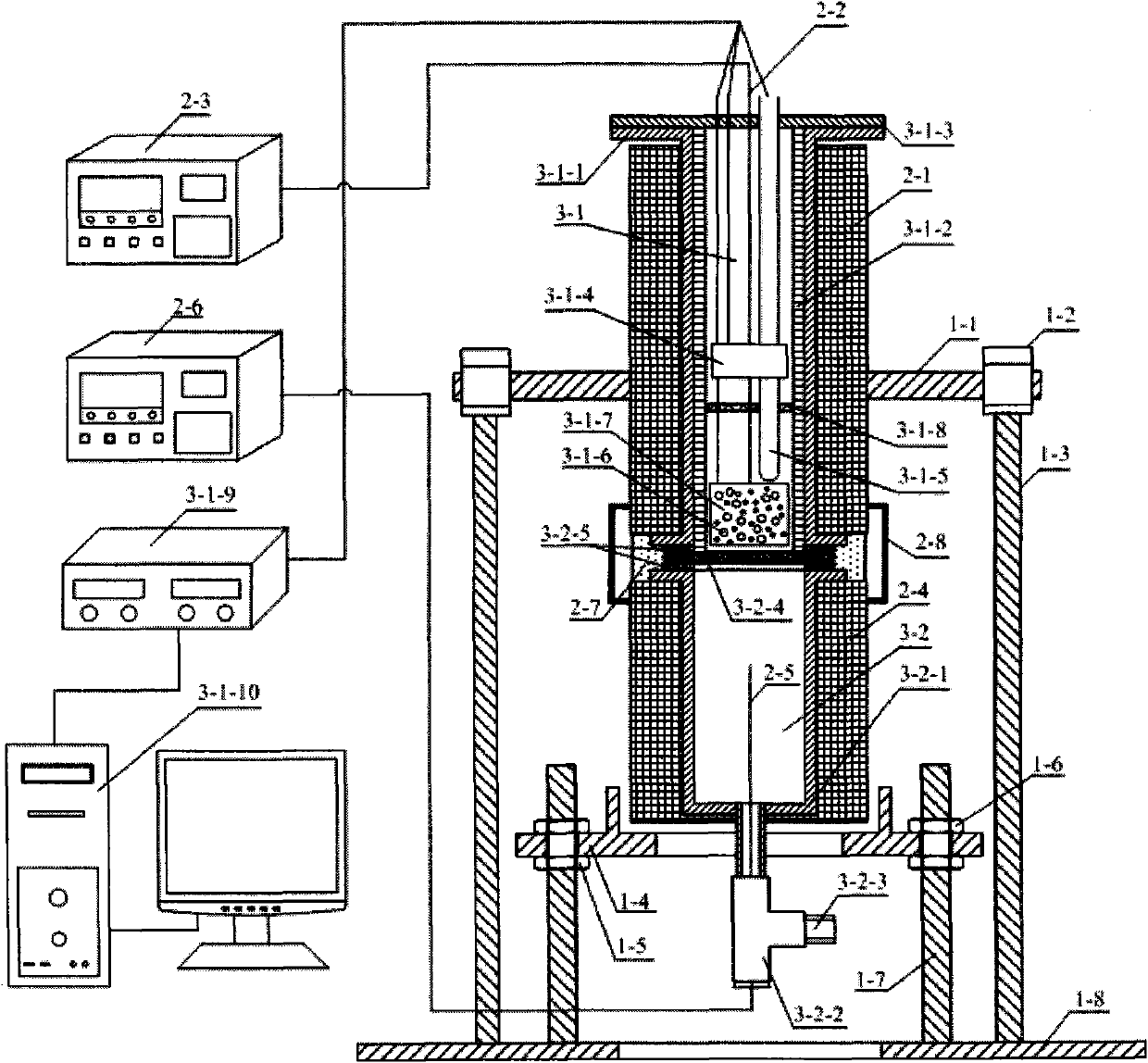

Test method and device for half cell of fluid bed electrode direct carbon fuel cell

A fuel cell and testing method technology, applied in fuel cells, fuel cell additives, measurement devices, etc., can solve the problems of increasing the difficulty of manufacturing electrode plates, processing costs, and difficulty in replacing electrode plates, avoiding electrolyte loss, storage and transportation. Difficulty, the effect of reducing the diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] First place the current collector on the bottom of the half-cell, then add a mixture of self-made bamboo activated carbon (0.5mm particle size) and 30g nickel particles (80-160 mesh) into the half-cell, and then fix the porous plate on the air distribution plate 10cm prevent the activated carbon from being suspended on the top of the molten carbonate and cannot contact the nickel particles, then put the auxiliary electrode, reference electrode and carbonate in sequence, and then cover the cover plate to start heating (the heating rate is 10K·min -1 ), the N introduced during the heating process 2 The flow rate is 60mL·min -1 , rise to preset temperature 923K, adjust O 2 , CO 2 and N 2 The flow rates are 10, 20, 275mL min -1 , connect the external circuit to test the half-cell polarization curve, see Image 6 .

Embodiment 2

[0052] First place the current collector on the bottom of the half-cell, then add a mixture of activated carbon fibers (0.5mm in particle size) and 30g of nickel particles (80-160 mesh) into the half-cell, and then fix the porous plate on the air distribution plate at 10cm to prevent Activated carbon is suspended on the top of the molten carbonate and cannot be in contact with the nickel particles, and then the auxiliary electrode, reference electrode and carbonate are placed in sequence, and then the cover plate is put on to start heating (the heating rate is 10K min -1 ), the N introduced during the heating process 2 The flow rate is 60mL·min -1 , up to preset 923K, adjust O 2 , CO 2 and N 2 The flow rates are 10, 20, 275mL min -1 , connect the external circuit to test the half-cell polarization curve, see Figure 7 .

Embodiment 3

[0054] First place the current collector on the bottom of the half-cell, then add a mixture of self-made bamboo activated carbon (0.5mm particle size) and 15g nickel particles (80-160 mesh) into the half-cell, and then fix the porous plate on the air distribution plate 10cm prevent the activated carbon from being suspended on the top of the molten carbonate and cannot contact the nickel particles, then put the auxiliary electrode, reference electrode and carbonate in sequence, and then cover the cover plate to start heating (the heating rate is 10K·min -1 ), the N introduced during the heating process 2 The flow rate is 60mL·min -1 , rise to pre-923K, adjust O 2 , CO 2 and N 2 The flow rates are 10, 20, 275mL min -1 , connect the external circuit to test the half-cell polarization curve, see Figure 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com