Patents

Literature

46results about How to "Improve energy grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

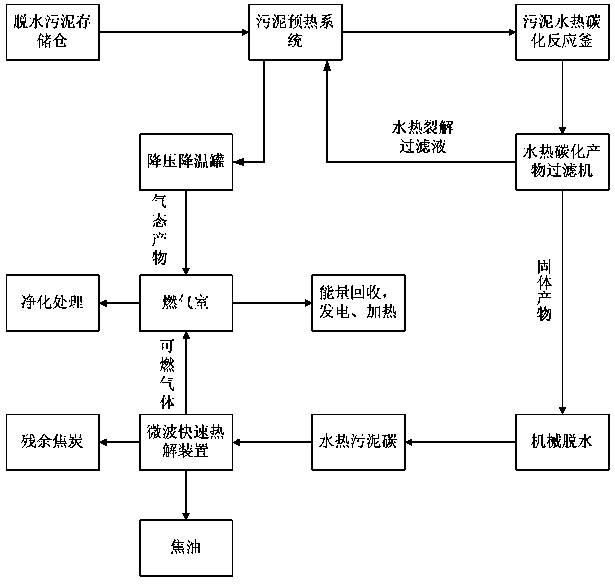

Comprehensive sludge treating method based on hydrothermal carbonization and fast microwave pyrolysis

InactiveCN104355519AImprove energy gradeOvercoming excessive moisture contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMoistureResource utilization

The invention discloses a comprehensive sludge treating method based on hydrothermal carbonization and fast microwave pyrolysis. The method comprises two steps of hydrothermal carbonization and fast microwave pyrolysis of sludge. The hydrothermal carbonization is applied to pretreatment of the sludge at an earlier stage, and can be used for solving the difficulties of high moisture and low heating value of the sludge and improving the energy grade of the sludge from the sources; fast microwave pyrolysis is performed on the sludge carbon subjected to the hydrothermal carbonization, liquid fuel and combustible gas with better productivity can be obtained, and the residue solid cokes can be used as industrial raw materials, so that the energy source recycling with high efficiency and low pollution for the sludge is realized. The method has the advantages of high resource utilization degree, cleanness, environment protection, low operating cost and wide application prospect. Besides, the method is a method for fast treating the sludge.

Owner:SOUTH CHINA UNIV OF TECH

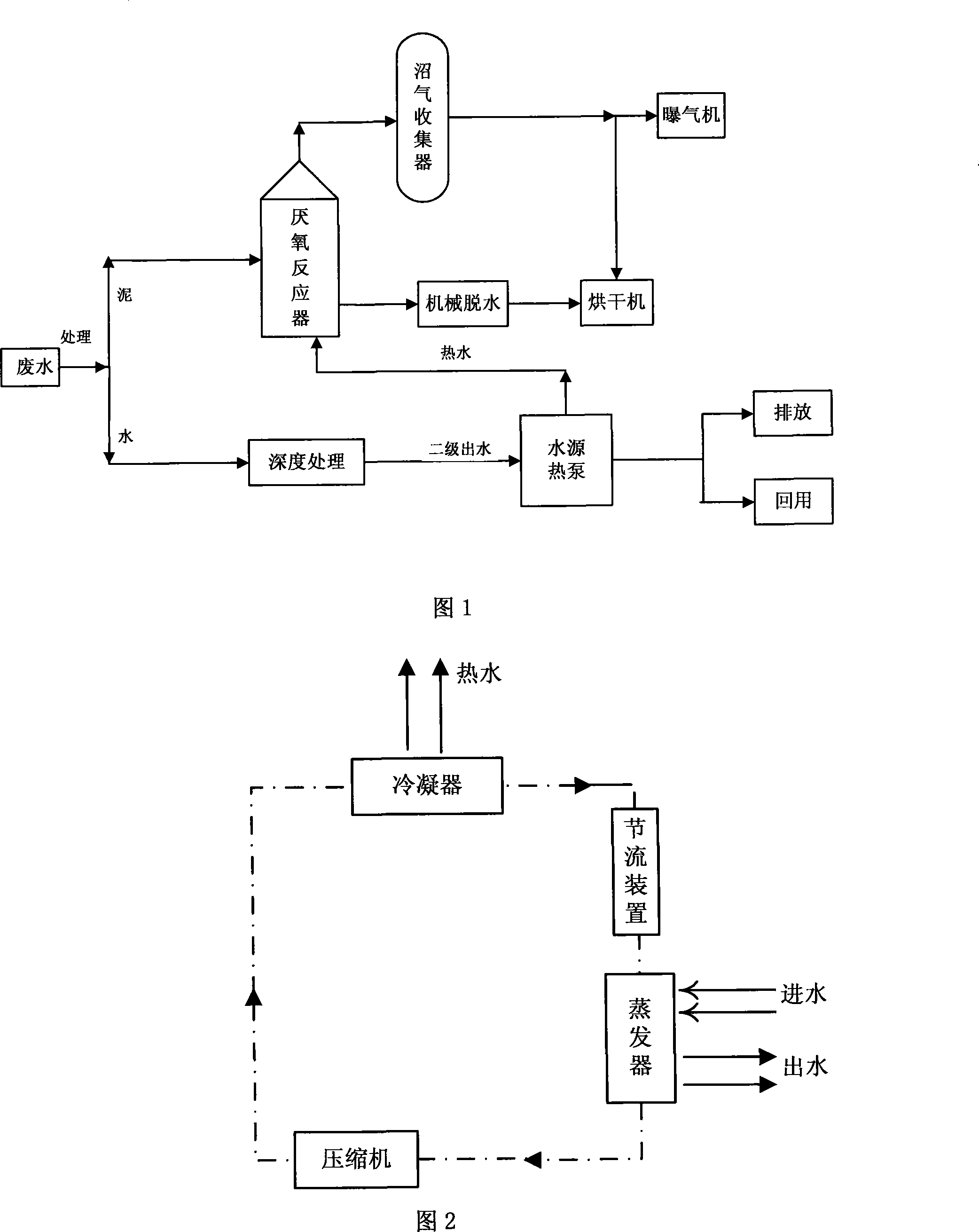

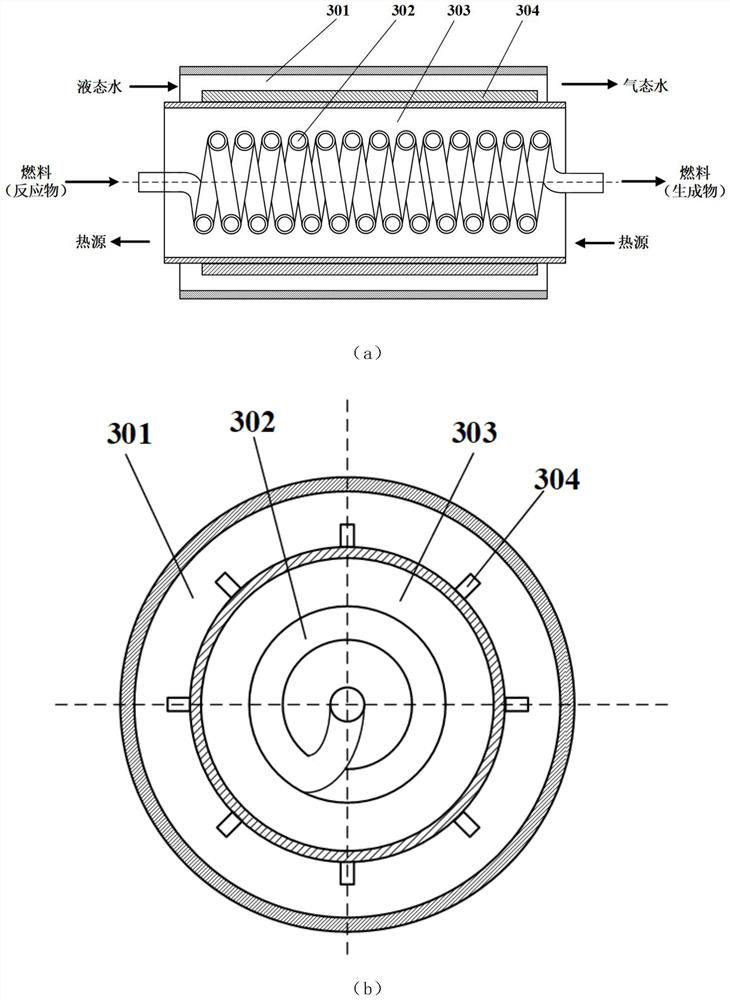

Water source heat pump and sludge anaerobic assimilation integration method and system

InactiveCN101239771AImprove energy gradeEnergy savingSludge treatment by de-watering/drying/thickeningHeat pumpsFertilizerMunicipal sewage

The present invention provides a water source heat pump and a sludge anaerobic digestion integration method and the system thereof, belongs to the filed of saving energy and lowering the consumption by the sewage treatment plant. The method uses the water source heat pump for realizing the recovery of low-grade heat energy in the discharging water of the sewage plant. The sludge generated by the municipal sewage plant enters the anaerobic reactor and is heated by the hot water provided by the heat pump which extracts heat from the discharged water to react for generating marsh gas, and the marsh gas is used for drying the sludge or driving the aeration blast engine. The digested sludge passes a series of processes such as mechanical dehydration and anhydration to obtain the dewatered sludge which can be used as the high quality fertilizer or solid fuel. The method and the system can realize the stabilization of the sludge and set the stage for the subsequent reducing and resource disposing of the sludge, the configuration of water, heat and energy at the inner part of the sewage plant can be optimized and the whole energy consumption of the sewage plant can be reduced for above 20%.

Owner:TSINGHUA UNIV

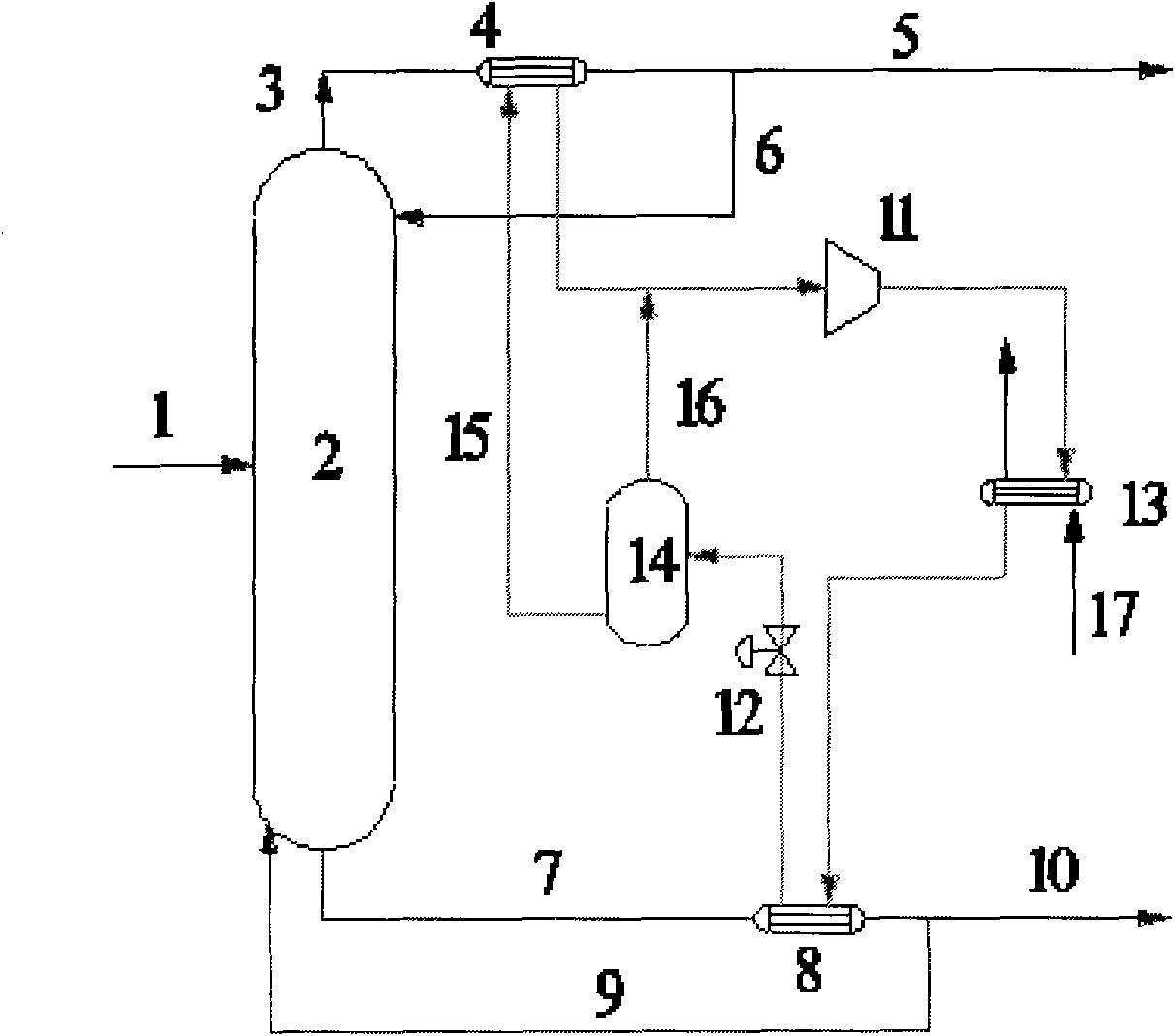

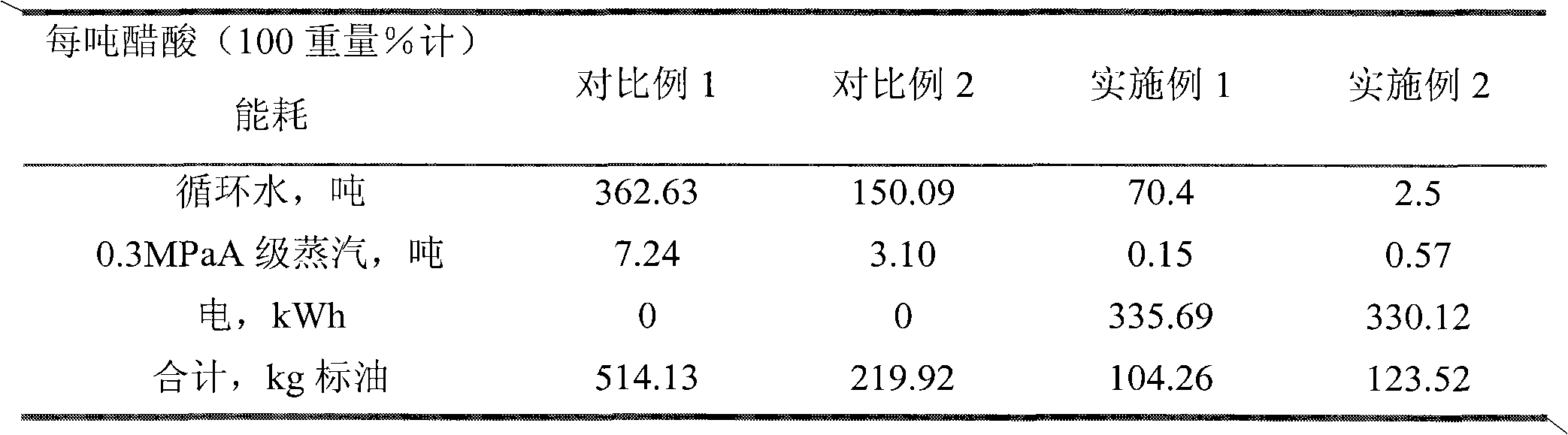

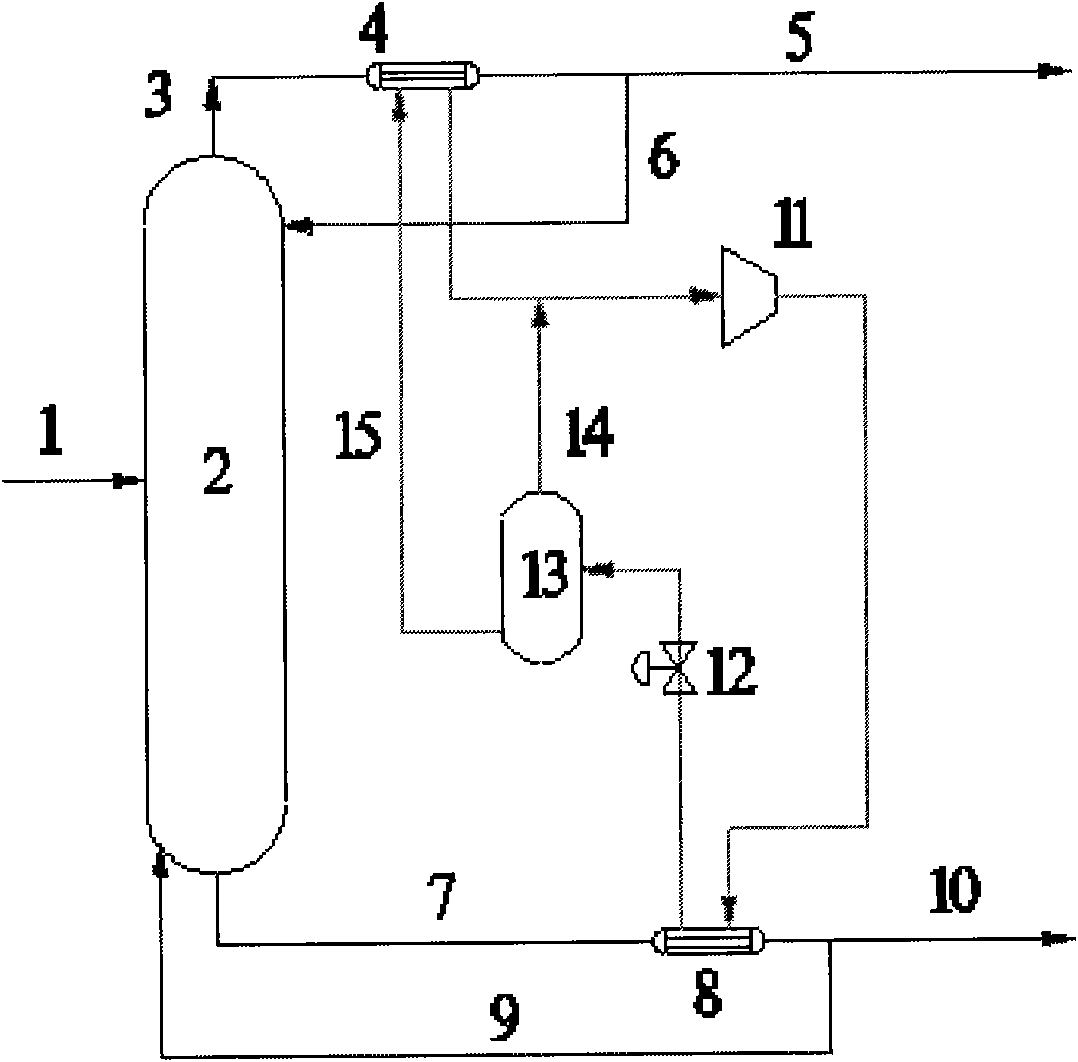

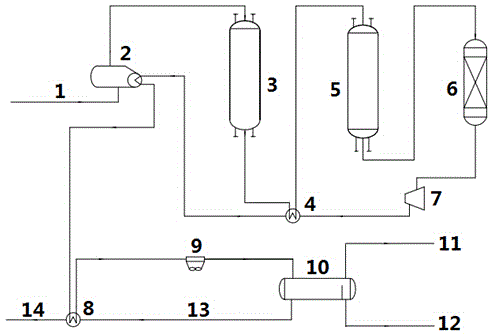

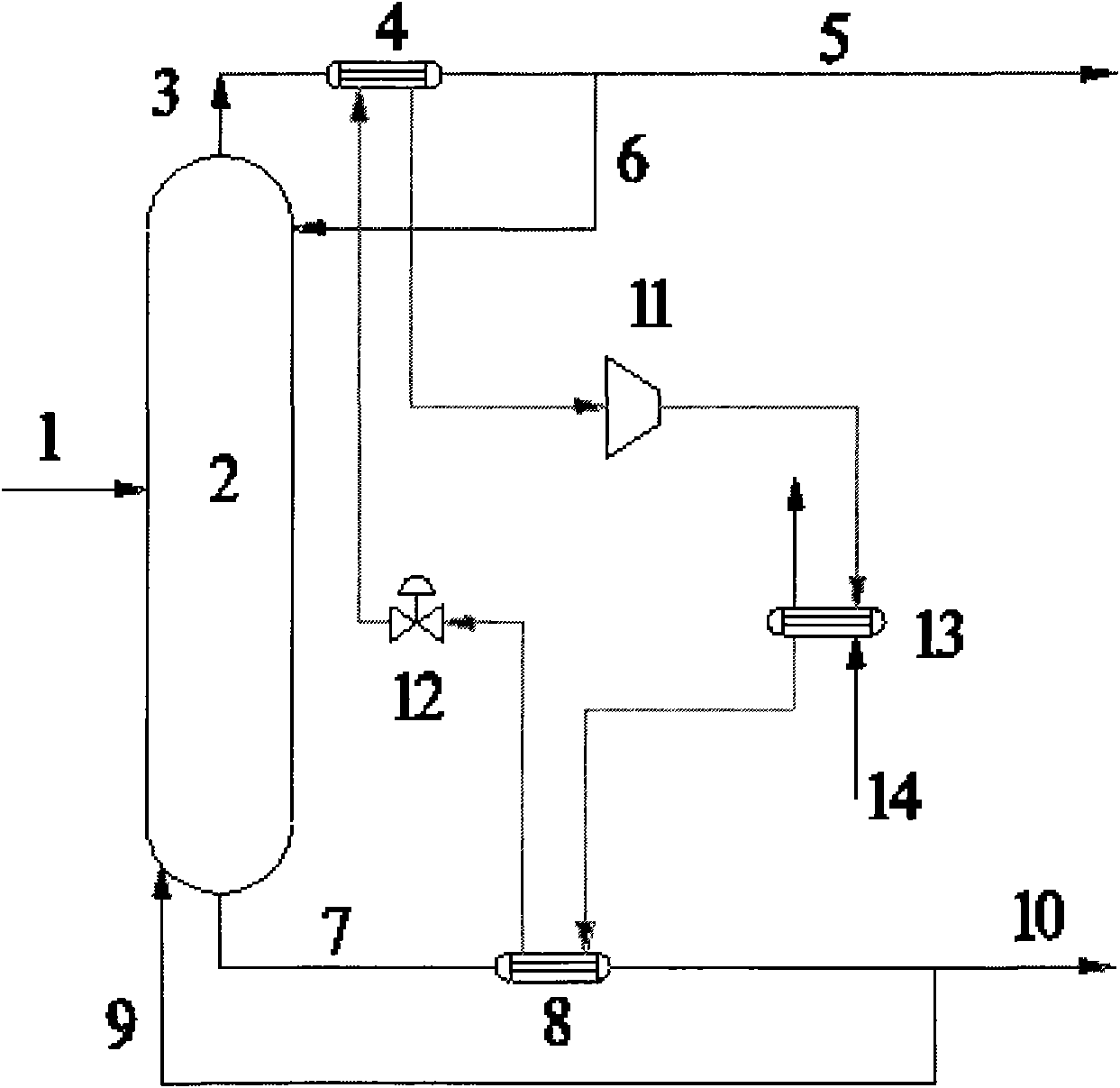

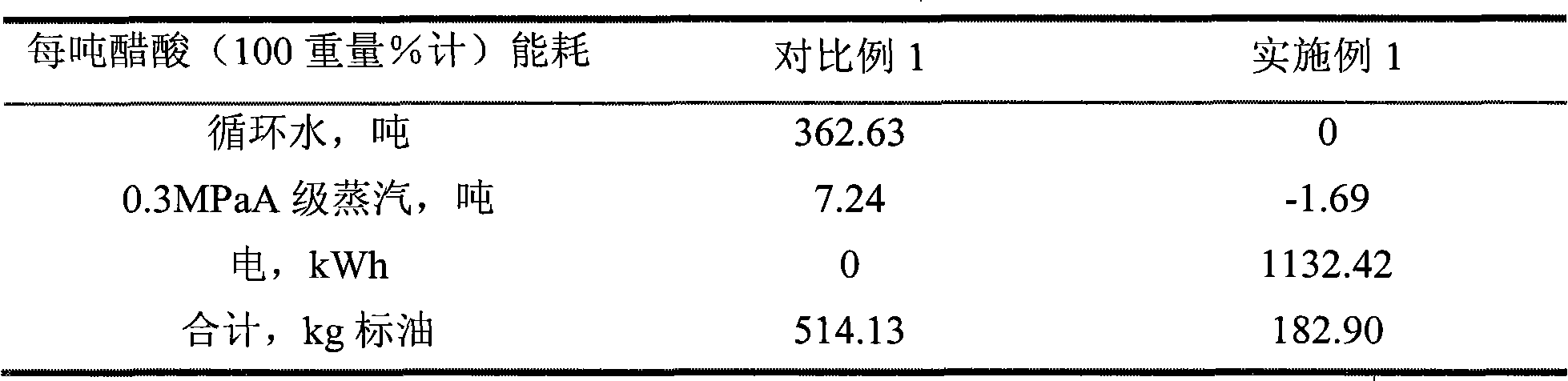

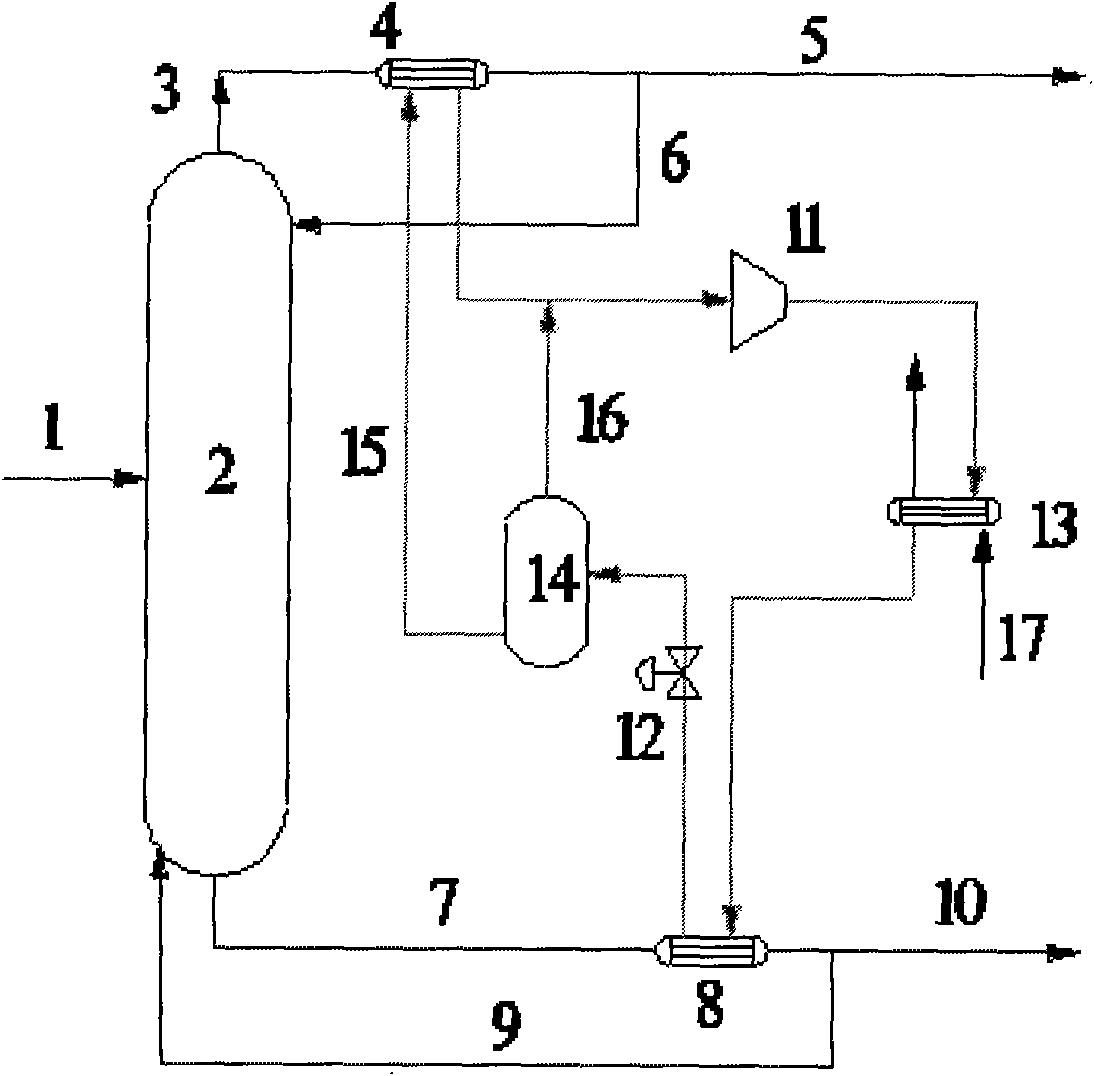

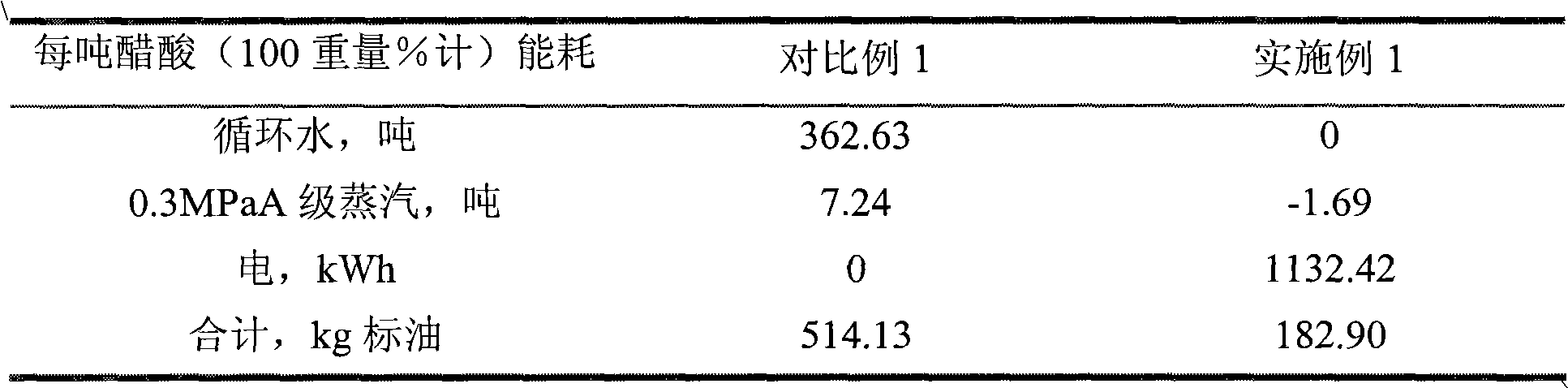

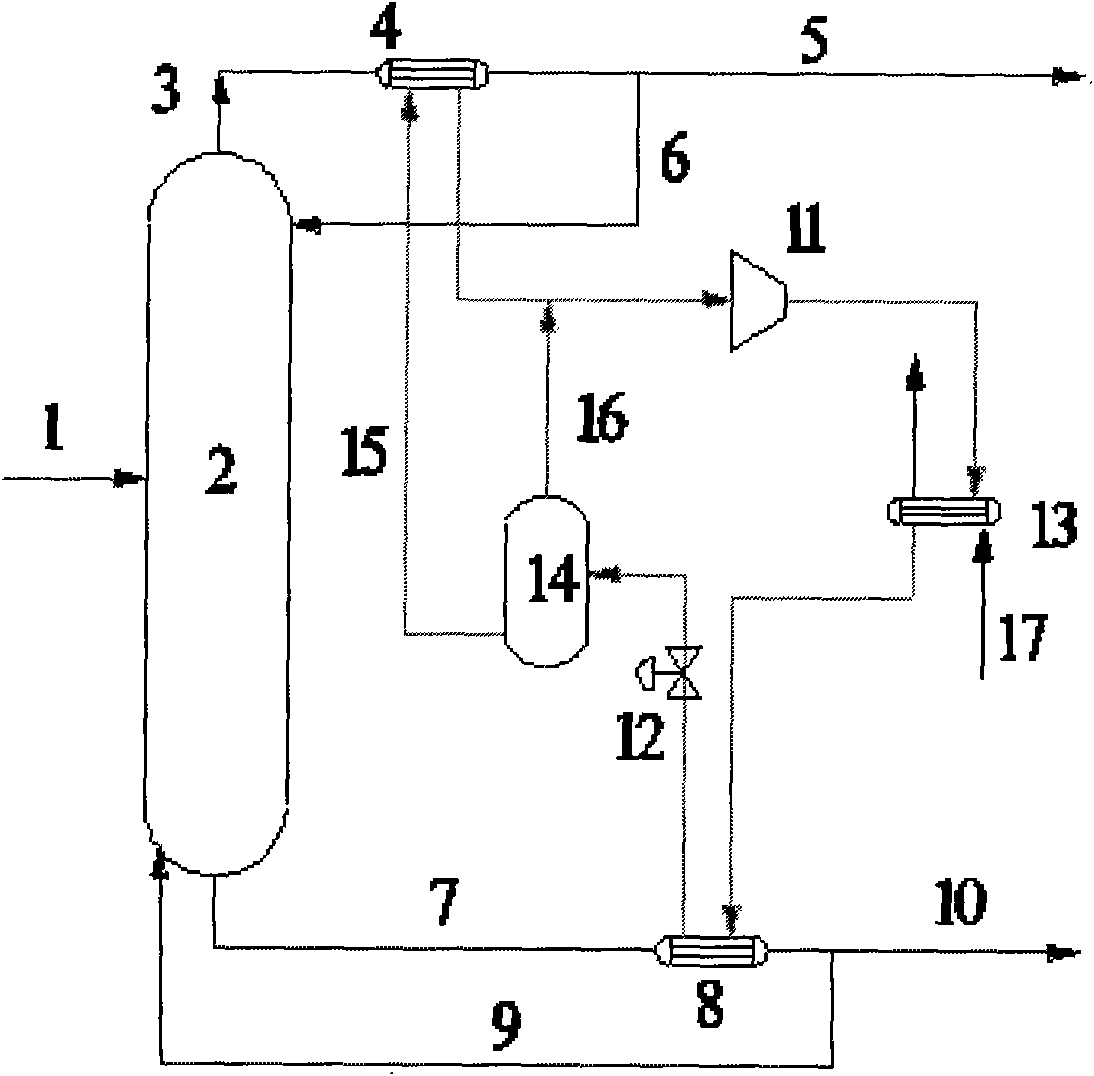

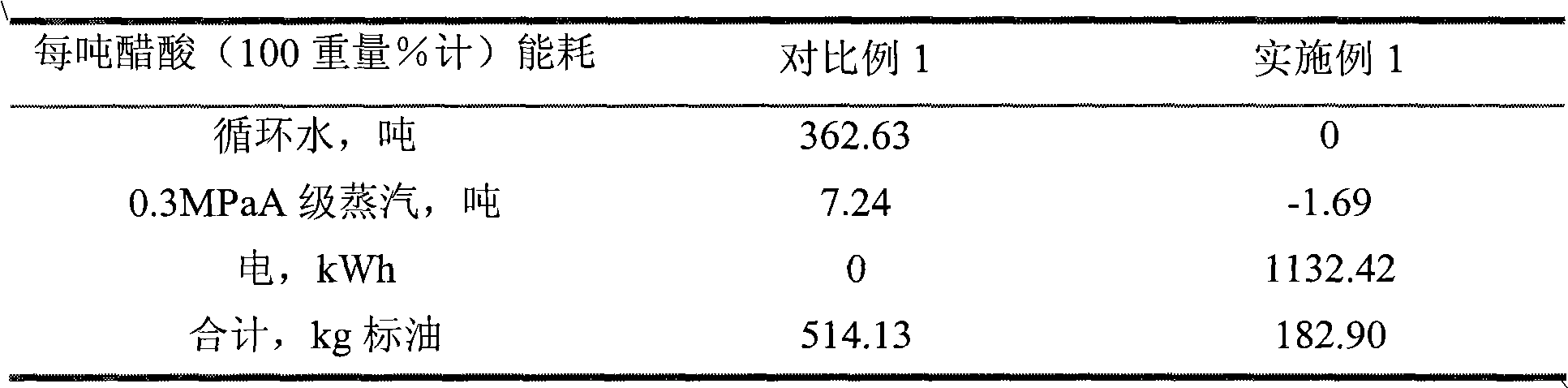

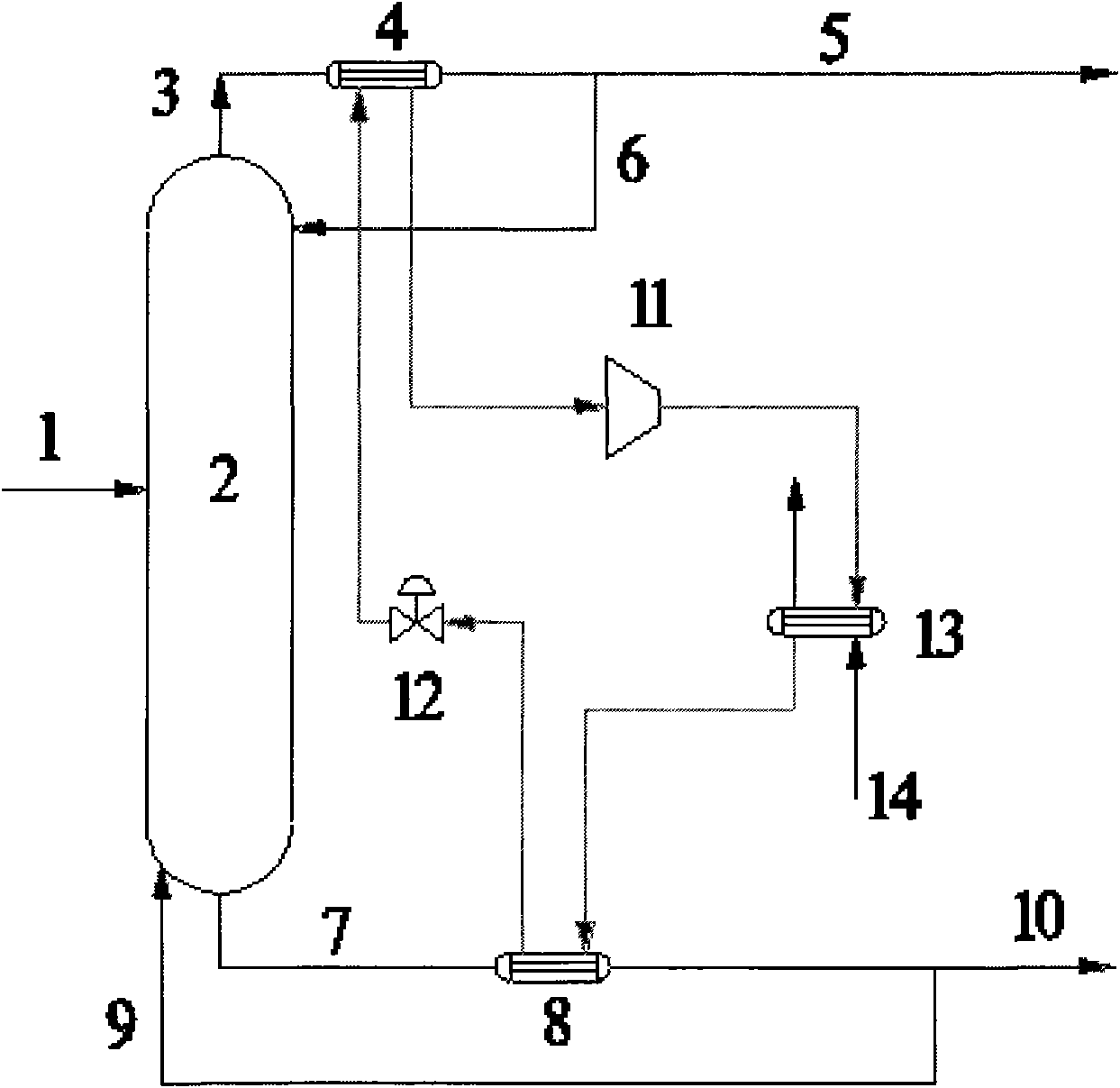

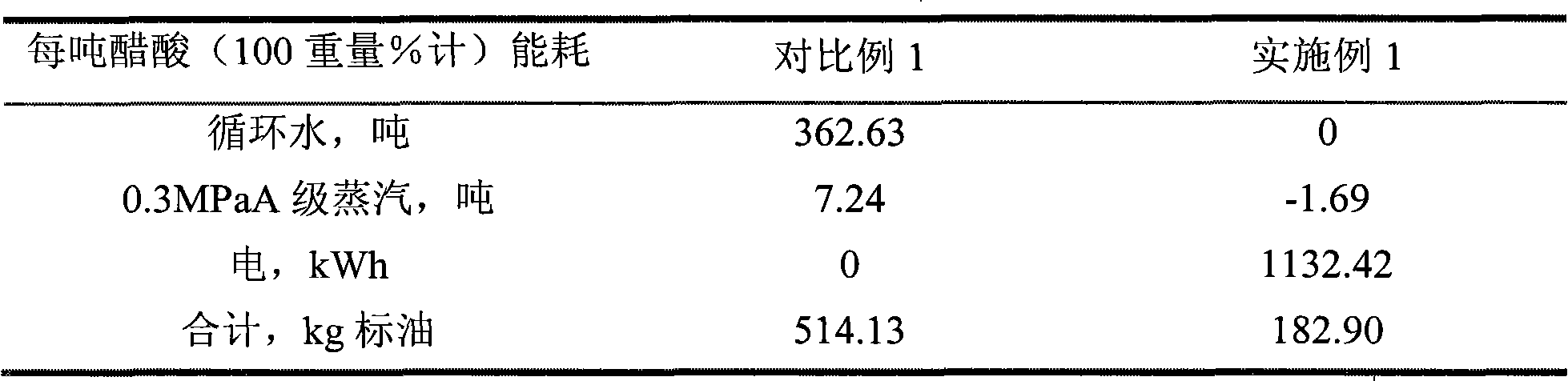

Method for separating acetic acid from water by rectification of acetic acid dehydrating tower

ActiveCN102451572AImprove stabilityAvoid direct accessFractional distillationCarboxylic compound separation/purificationChemistrySuperheater

The invention relates to a method for separating acetic acid from water by rectification of an acetic acid dehydrating tower, mainly solving the problems of high energy consumption, high equipment manufacture cost and high operation cost in a process of dehydrating acetic acid in the prior art. The method comprises the steps of: carrying out azeotropic distillation by adopting the acetic acid dehydrating tower for dehydrating, adopting water or cyclohexane in a heat pump circulation as a heat exchange medium, absorbing heat released by condensation of top discharged materials of the acetic acid dehydrating tower through a heat exchange medium in a closed heat pump process, raising the temperature after the heat exchange medium absorbs the heat of the top discharged materials and then compressed, desuperheating high-temperature overheat steam by a desuperheating device to form saturated steam, introducing into a kettle reboiler and exchanging heat with bottom discharged materials; throttling and decompressing the steam subjected to kettle heat exchange and then entering into a gas and liquid separation tank, enabling the separated liquid phase to a tower top condenser for exchanging heat, mixing the separated gas phase with gas at an outlet of the tower top condenser together to enter into a compressor for exchanging heat with a kettle again. According to the technical scheme, the problem is better solved, thus the invention can be applied to industrial production of separating the acetic acid from the water.

Owner:CHINA PETROLEUM & CHEM CORP +1

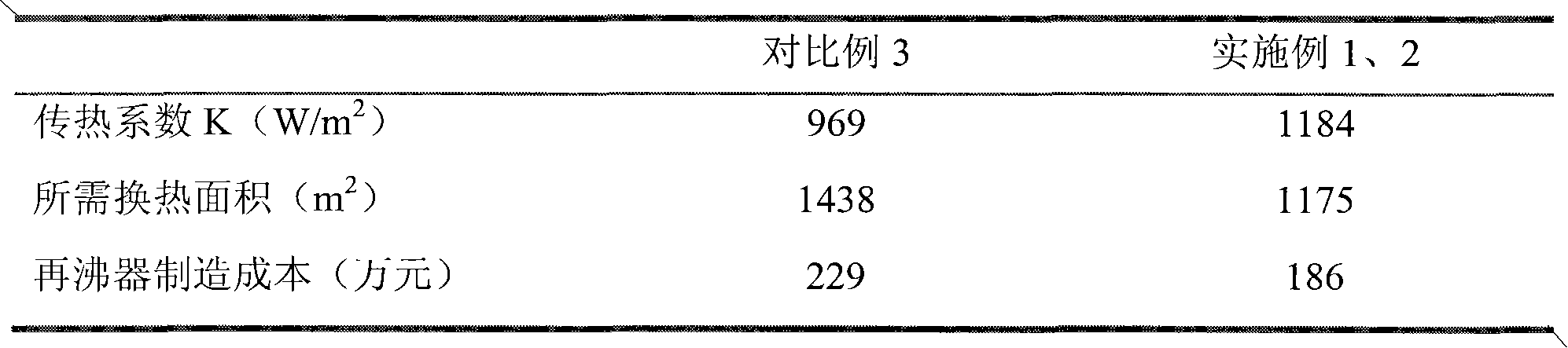

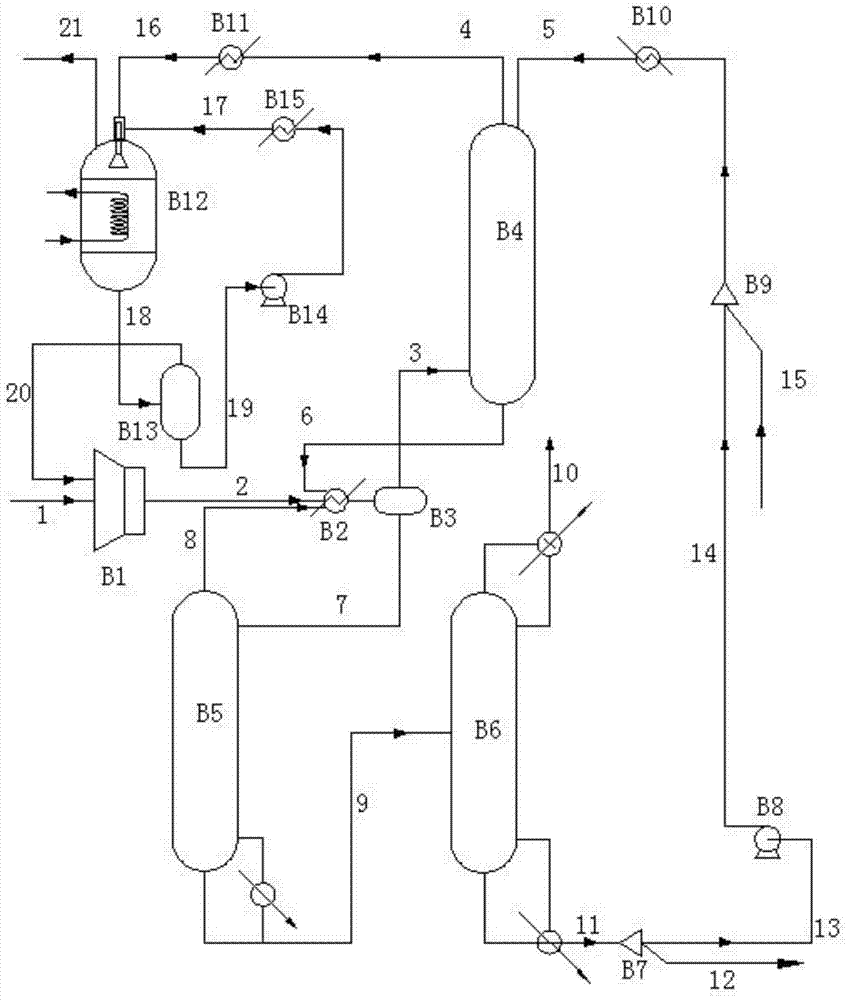

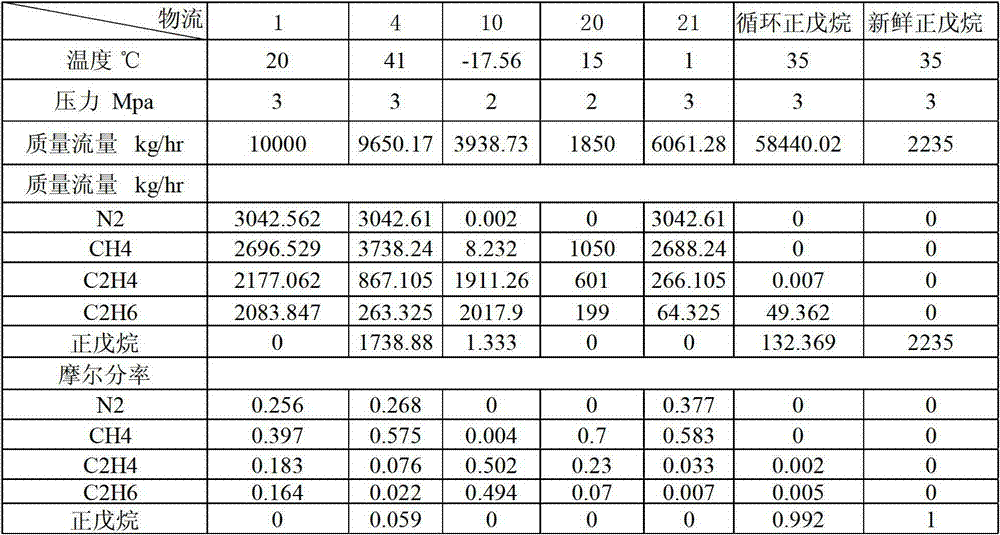

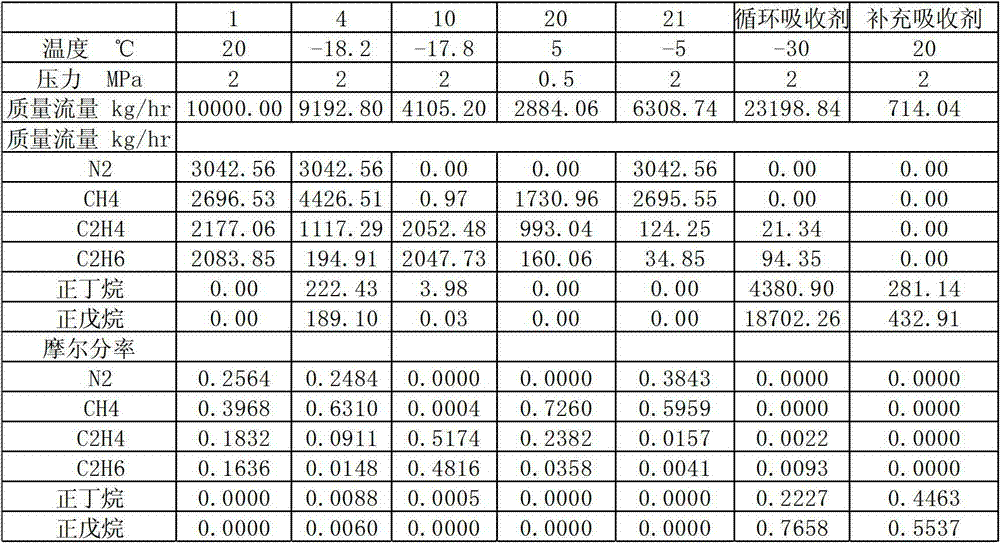

Absorption and hydration coupling device and method for separating ethylene and ethane in catalytic cracking dry gas or ethylene pyrolysis gas

InactiveCN103030494ALow costImprove energy gradeHydrocarbonsEthylene productionHigh concentrationSeparation technology

The invention provides an absorption and hydration coupling device and a method for separating ethylene and ethane in catalytic cracking dry gas or ethylene pyrolysis gas. The method is divided into two processes: the catalytic dry gas or the ethylene pyrolysis gas enters an absorption separation process; a high-purity C2 product is obtained through absorption, desorption and absorbent regeneration; C2 lean gas at the top of an absorption tower enters a hydration separation process; and then C2 gas recovered in hydration separation and virgin gas are merged and return to the absorption separation process. The absorption separation process and the hydrate separation process are combined; the advantages that the separation efficiency of an absorption method in a high concentration area is high, and the separation efficiency of a hydration separation method in a low concentration area is high are exerted; the solvent amount required by the absorption process is reduced; the defects that the hydration separation purity is not high and the separation efficiency is low are avoided; the purity of the obtained C2 product can reach 99.6%; and the C2 product can directly enter an ethylene tower. The method is suitable for separating the recovered C2 from the catalytic cracking dry gas or the ethylene pyrolysis gas, and is hopeful for substituting a cryogenic separation technology.

Owner:TIANJIN UNIV

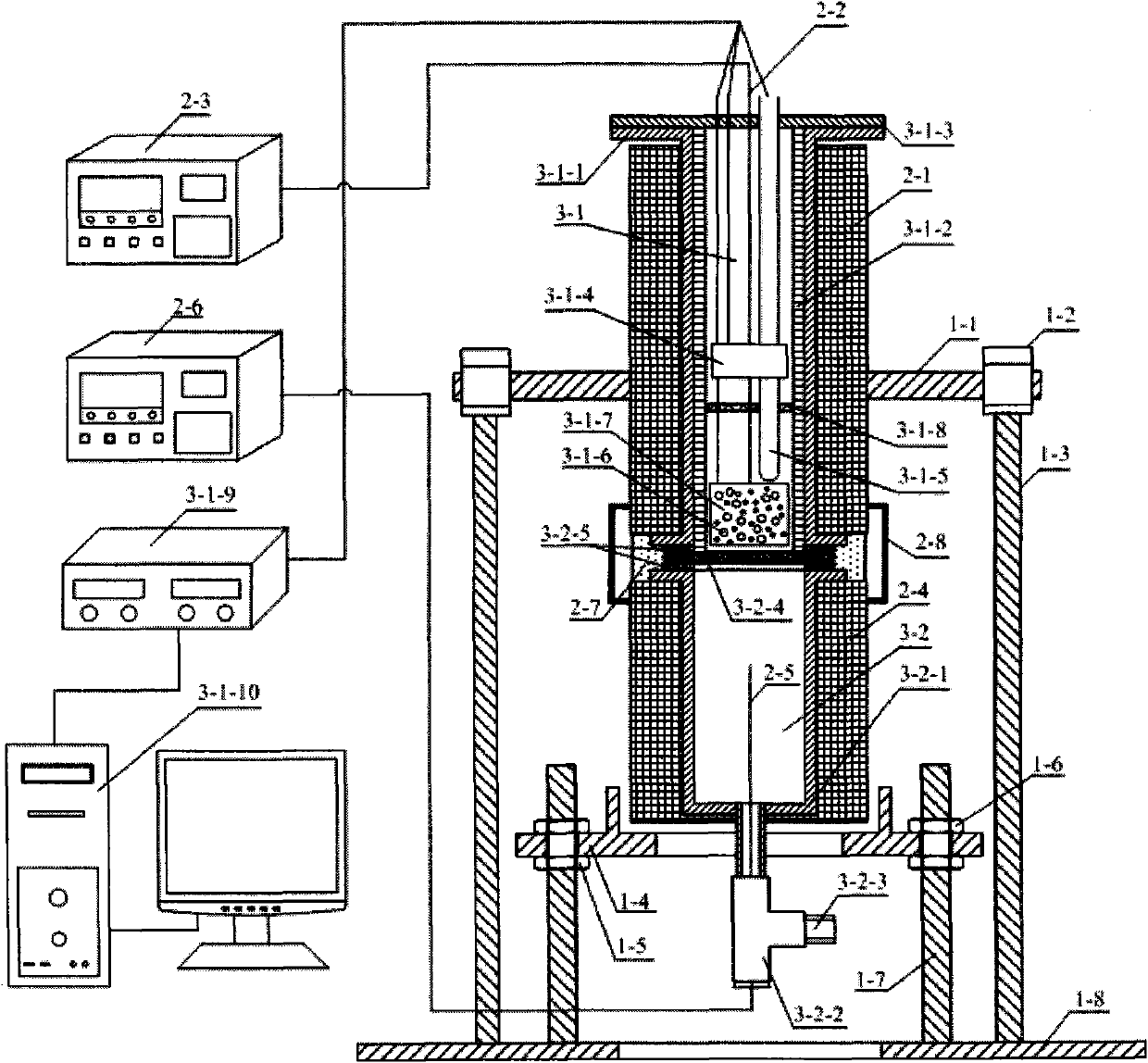

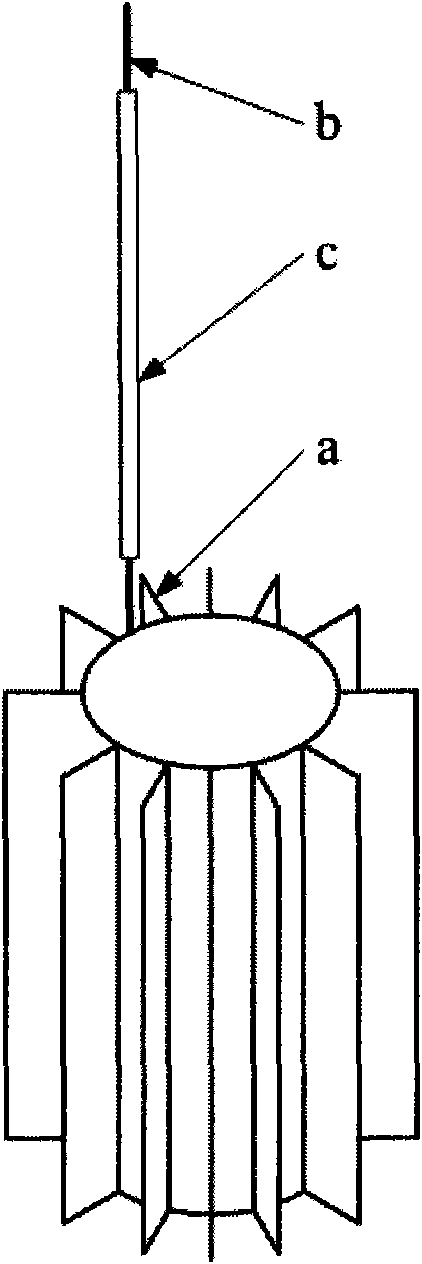

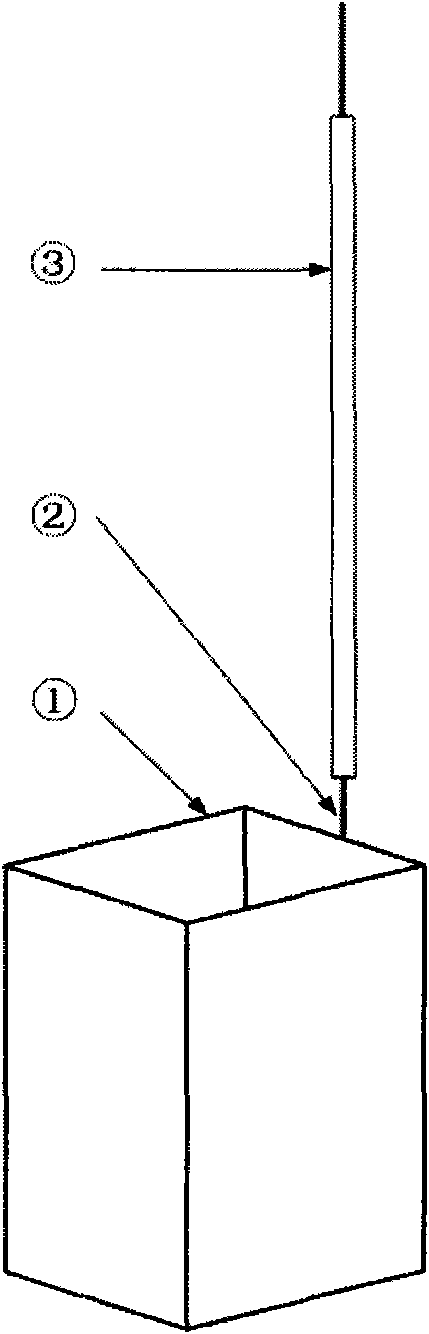

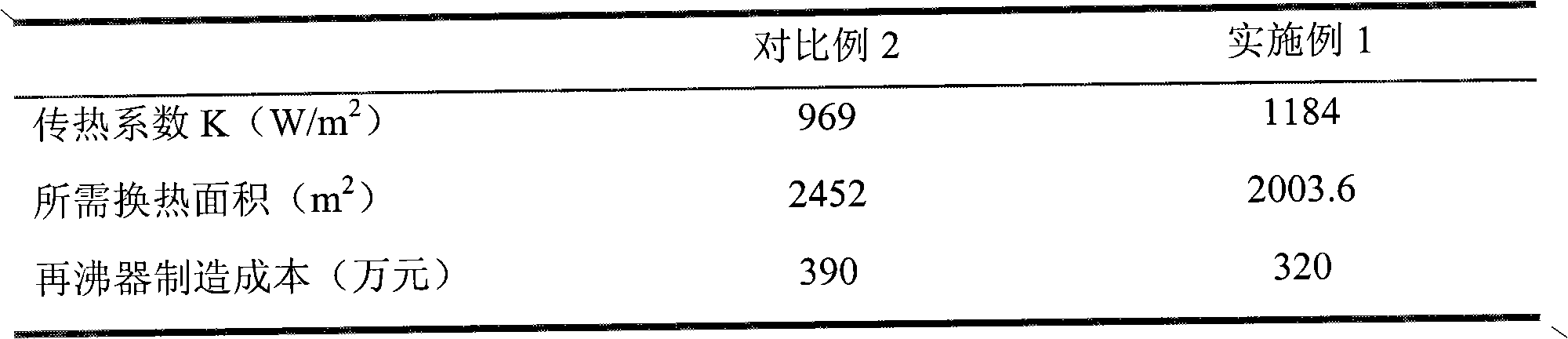

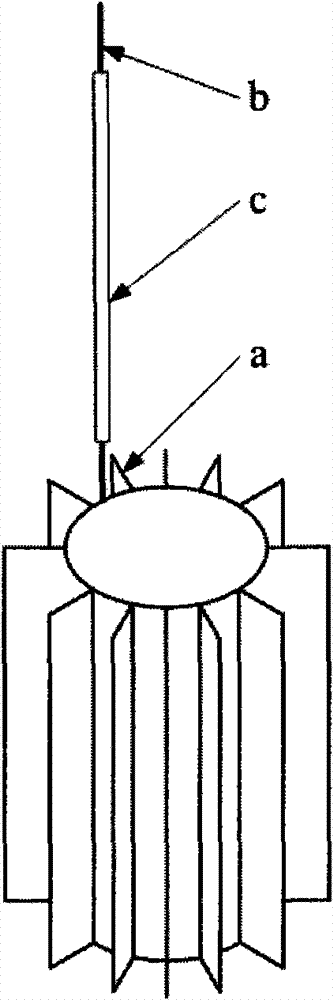

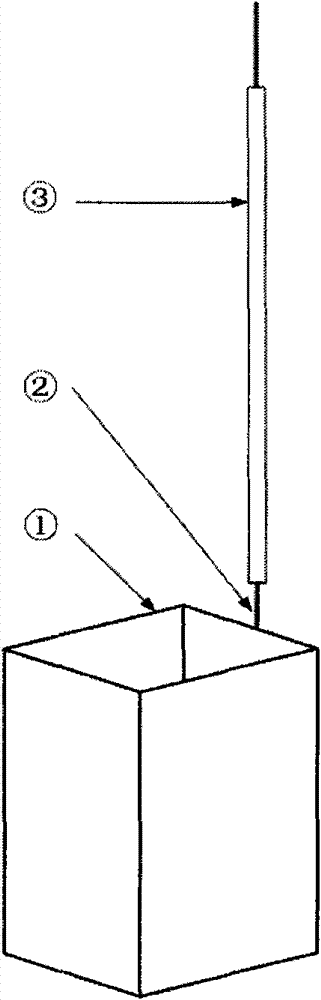

Test method and device for half cell of fluid bed electrode direct carbon fuel cell

InactiveCN102004225AHigh activitySimple structureFuel cell auxillariesElectrical testingPtru catalystElectrical battery

The invention provides a test method and device for half cell of fluid bed electrode direct carbon fuel cell. The method comprises the following steps: firstly, arranging a current collector and the mixture of carbon fuel and catalyst granules in a half cell; secondly, fixing a porous plate in a preset position, and sequentially adding an auxiliary electrode, a reference electrode and carbonate; then, introducing nitrogen gas into the half cell, heating the nitrogen gas to a preset reaction temperature, regulating the flow of the nitrogen gas, and introducing oxygen gas and carbon dioxide into the reference electrode to balance the gas; and finally, connecting to an external circuit to start experiment. The device for realizing the testing method is a half-cell reaction device and comprises a half-cell reactor and a gas preheater, two electric heating devices are respectively used for carrying out temperature control on the half-cell reactor and the gas preheater, and a rotatable support structure is used for supporting and fixing the half-cell reaction device and the electric heating devices and realizing the dumpage of molten carbonate in the half cell. By making full use of theadvantages of the fluid bed electrode and the direct carbon fuel cell, the performance of the cell can be improved.

Owner:SOUTHEAST UNIV

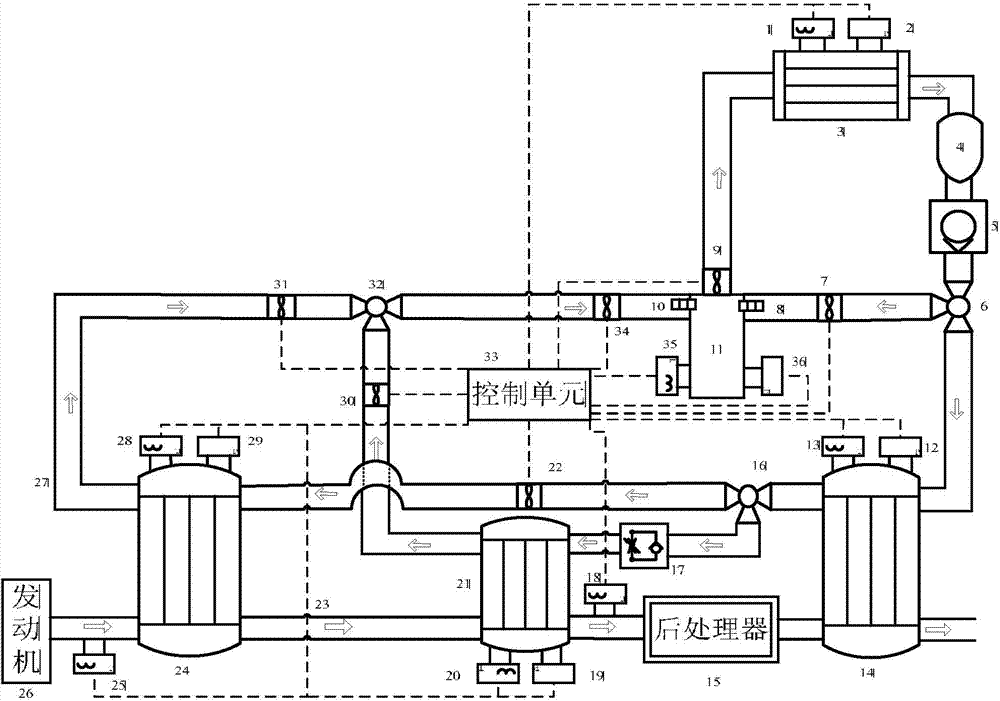

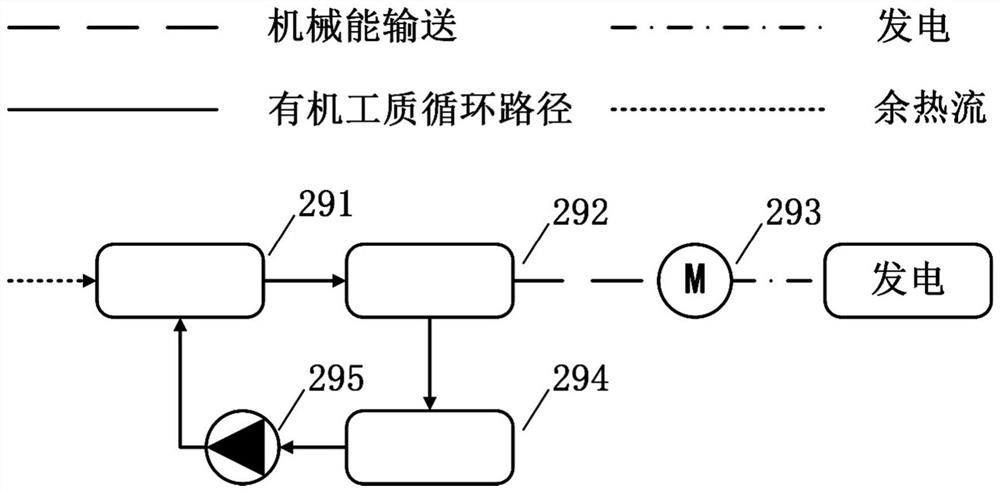

Supercritical heat accumulating type organic Rankine cycle exhaust afterheat comprehensive utilization device

InactiveCN104712403AEasy to implementTake advantage ofInternal combustion piston enginesExhaust apparatusOrganic Rankine cyclePollutant emissions

The invention relates to a supercritical heat accumulating type organic Rankine cycle exhaust afterheat comprehensive utilization device which comprises a subcritical ORC module, a supercritical ORC module and a supercritical heat accumulating module. The supercritical heat accumulating type organic Rankine cycle exhaust afterheat comprehensive utilization device is mainly composed of a condenser, a working medium storage tank, an electromagnetic valve, a working medium pump, an expansion machine, a preheater, a postprocessor, a supercritical heat accumulator, an overheating evaporator, a control unit and the like. The exhaust temperature is stabilized within a certain range by the supercritical heat accumulator, then exhaust enters the postprocessor, and the postprocessor is made to keep high purification efficiency and lower pollution emission under most of the working conditions of an engine. Meanwhile, organic Rankine cycle is used for recovering the heat of the exhaust to improve the utilization rate of energy. The supercritical heat accumulating type organic Rankine cycle exhaust afterheat comprehensive utilization device has the advantages that the organic Rankine cycle is used for achieving low pollution emission and efficient energy utilization.

Owner:JILIN UNIV

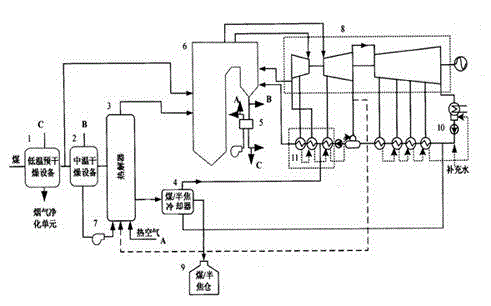

Coal-fired power plant and low-rank coal upgrading integrated system and comprehensive utilization of upgraded product

InactiveCN104610991AIncrease added valueImprove Energy TasteCoke quenchingDrying solid materials with heatThermodynamicsWater vapor

The invention discloses a coal-fired power plant and low-rank coal upgrading integrated system and comprehensive utilization of an upgraded product, and belongs to the technical field of upgrading conversion and comprehensive utilization of low-rank coal resources. The system comprises pre-drying equipment, a pyrolyzer, a coal / semi-coke cooler and auxiliary equipment. After being dried by pre-drying equipment, a part of low-rank coal enters a boiler for burning, and the rest enters the pyrolyzer; the coal chemically reacts with flue gas, air and water vapor in the pyrolyzer, and the generated blended fuel is fed into a furnace chamber for burning; upgraded coal is cooled through the coal / semi-coke cooler and then fed into a coal / semi-coke bin for storing. The system has the advantages as follows: the low-rank coal is upgraded, converted and comprehensively used while generating loads of a coal-fired power plant are met, so that coal / semi-coke, which is high in energy grade, and low in activity, and can be safely transported at a long distance, is obtained, and has an extremely high practical value, and the technical difficulties that the low-rank coal is easy to spontaneously combust and high in moisture are solved.

Owner:UNIV OF WESTERN AUSTRALIA +1

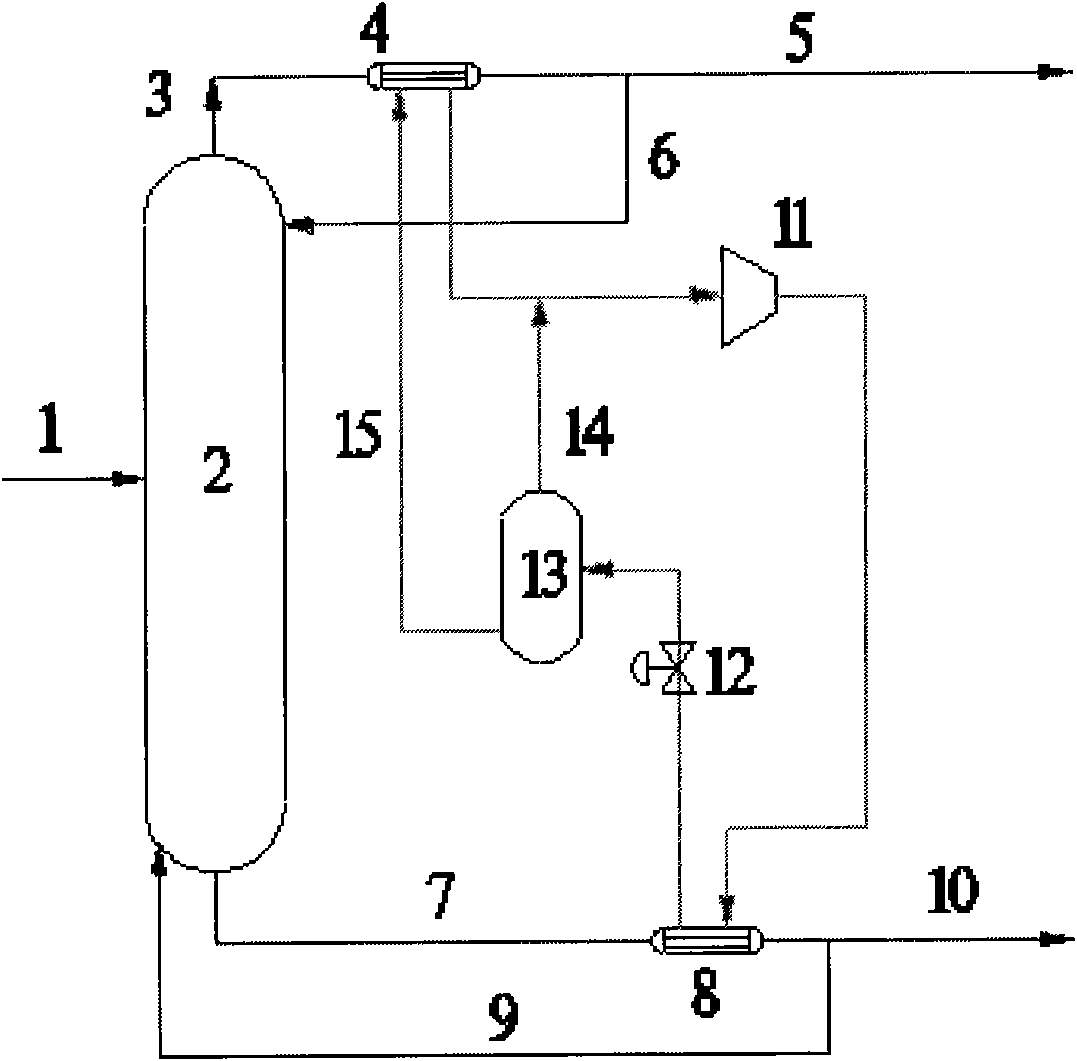

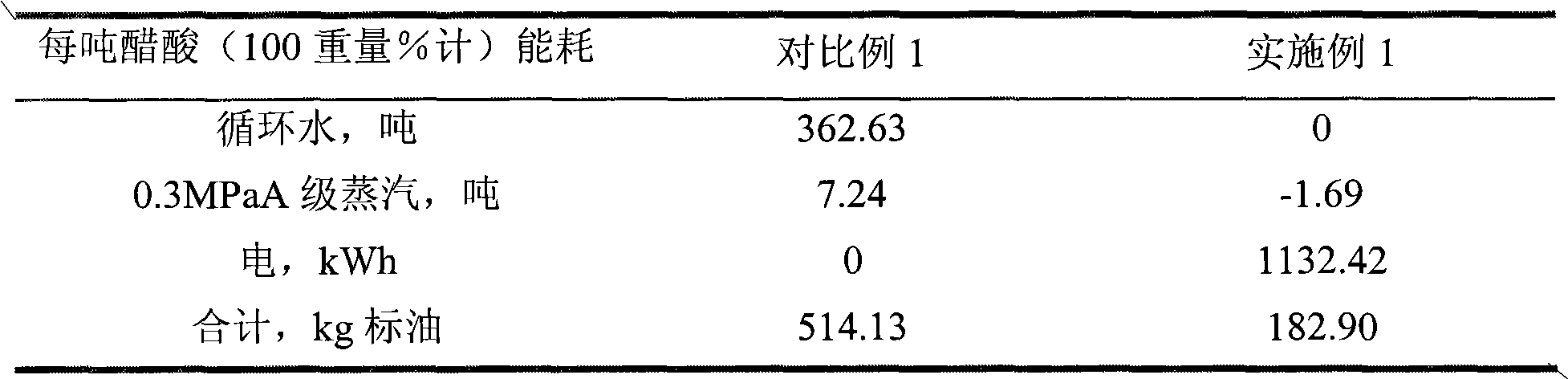

Method for separating acetic acid from water

ActiveCN102452925AAvoid equipment wear and tearImprove stabilityCarboxylic compound separation/purificationAceric acidChemistry

The invention relates to a method for separating acetic acid from water, which mainly solves the problems of high energy consumption and high operating cost in an acetic acid dehydration process in the prior art. In the invention, distillation and dehydration are carried out by pressurizing an acetic acid dehydration tower, water is used as a heat exchange medium in heat pump circulation, the heat released by condensing the discharged material at the top of the acetic acid dehydration tower is absorbed by a heat exchange medium in a closed heat pump process, the heat exchange medium after absorbing the energy of the discharged material at the top of the tower is compressed by a compressor so as to raise temperature, the high-temperature steam is used for carrying out heat exchange with the discharged material at the bottom of the tower in a tower kettle reboiler, the steam subjected to heat exchange in the tower kettle enters a gas-liquid separation tank after decompression, the separated liquid phase enters a condenser at the top of the tower to carry out heat exchange, and the separated gas phase is mixed with the gas at the outlet of the condenser at the top of the tower to enter the compressor, thereby being used for carrying out heat exchange again with the tower kettle. The technical scheme provided by the invention better solves the problems and can be applied to industrial production for separating acetic acid from water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy recycling method for process for preparing propylene from oxygenated compounds

InactiveCN104086346AImprove energy gradeDeepen the heat transfer depthChemical industryHydrocarbon from oxygen organic compoundsOrganic acidChemistry

The invention discloses an energy recycling method for a process for preparing propylene from oxygenated compounds, for mainly solving the problems that in the prior art, a heating furnace is high in heat load, low in heat exchange depth and low in efficiency level. The adopted technical scheme comprises the following steps: (1) desorbing micromolecule organic acid from an oxygenated compound prepared propylene reactor outlet product by using a deacidification reactor, so as to obtain a high temperature material flow I; (2) compressing and heating the high temperature material flow I, so as to obtain a high temperature material flow II; and (3) sequentially feeding the high temperature material flow II into a raw material gas preheater, a methanol gasifier and a circulation water preheater for respectively preheating a raw material gas, gasifying methanol and preheating circulation water. The method saves the energy consumption of a heating furnace of a conventional process and improves the process efficacy level, and meanwhile as the compression section of the product is brought forward, a better effect is achieved in phase separation, and the content of water in gas phase and oil phase is greatly reduced.

Owner:ZHEJIANG UNIV

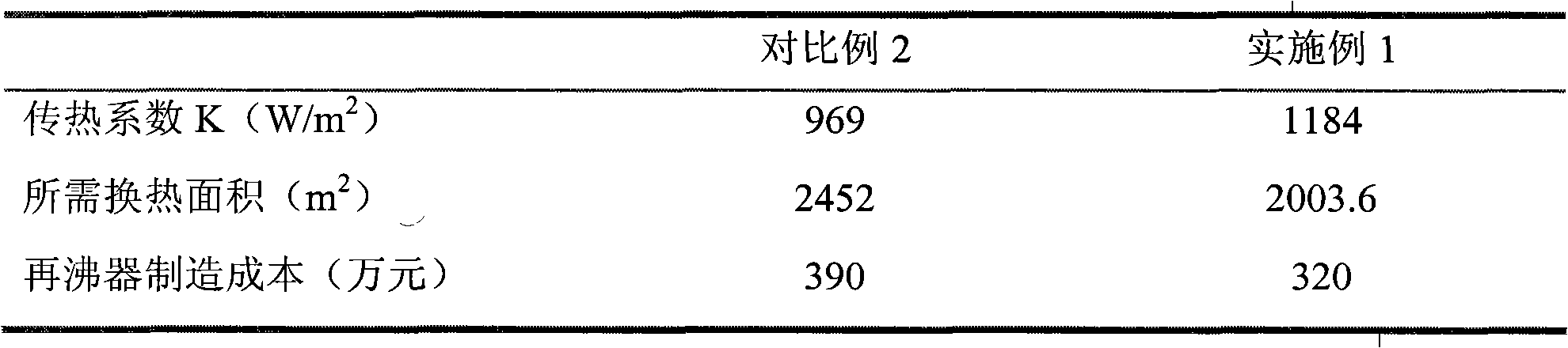

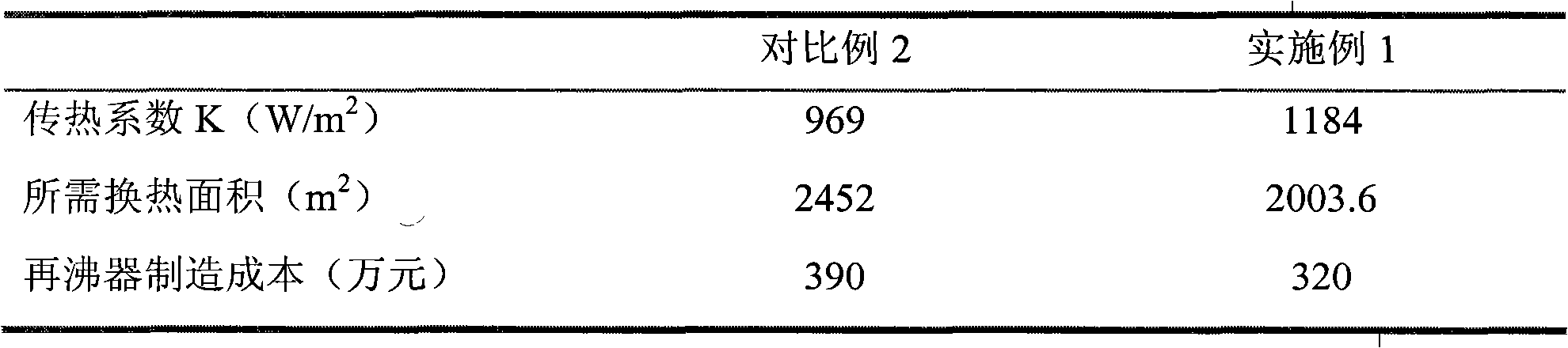

Method for separating acetic acid and water

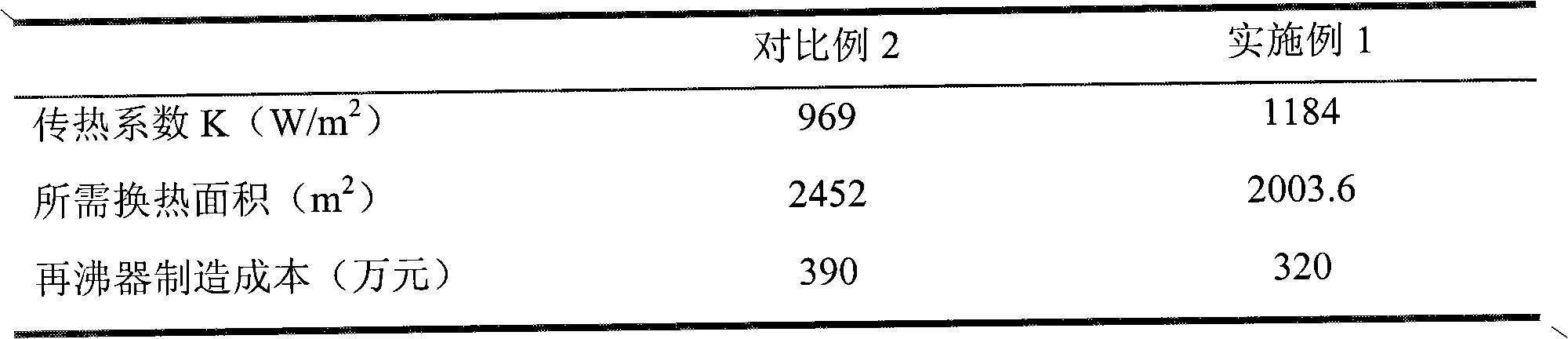

ActiveCN102452926AIncrease the heat exchange areaReduce dosageCarboxylic compound separation/purificationState of artAcetic acid

The invention relates to a method for separating acetic acid and water, mainly solving the problems in the prior art that the energy consumption is high in acetic acid dehydrating process and equipment manufacturing cost is high. The technical scheme of the method is as follows: rectifying and dehydrating by adding pressure to an acetic acid dehydrating tower; using water as a heat-transfer medium during a heat pump cycle; absorbing heat released from condensation on materials discharged from the acetic acid dehydrating tower top by the heat-transfer medium in a closed heat pump flow; compressing the heat-transfer medium having absorbed the energy of the materials discharged from the tower top by a compressing machine, wherein the temperature of the medium is raised then; desuperheating the high temperature superheated steam by a desuperheating device to form saturated steam, and filling the steam in a tower kettle reboiler to exchange heat with the discharged materials from the tower bottom. The method with the above technical scheme better solves the problems in the prior art, and can be applied in industrial production for separating acetic acid and water.

Owner:CHINA PETROLEUM & CHEM CORP +1

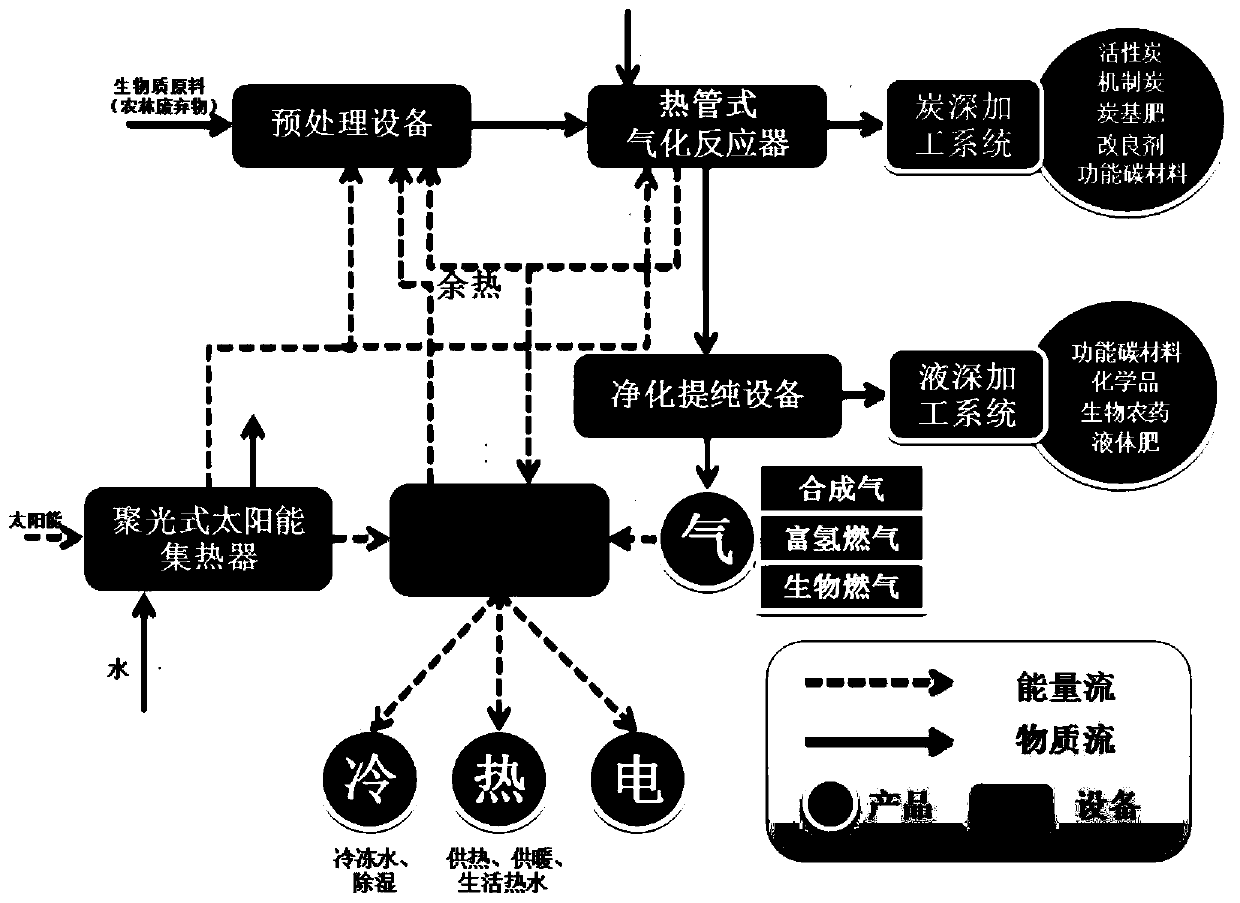

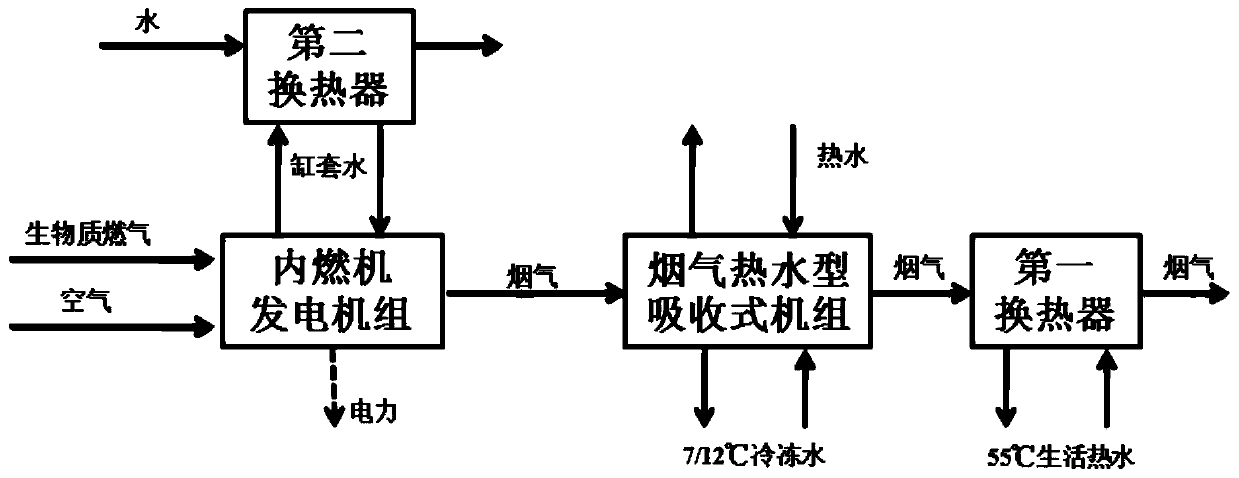

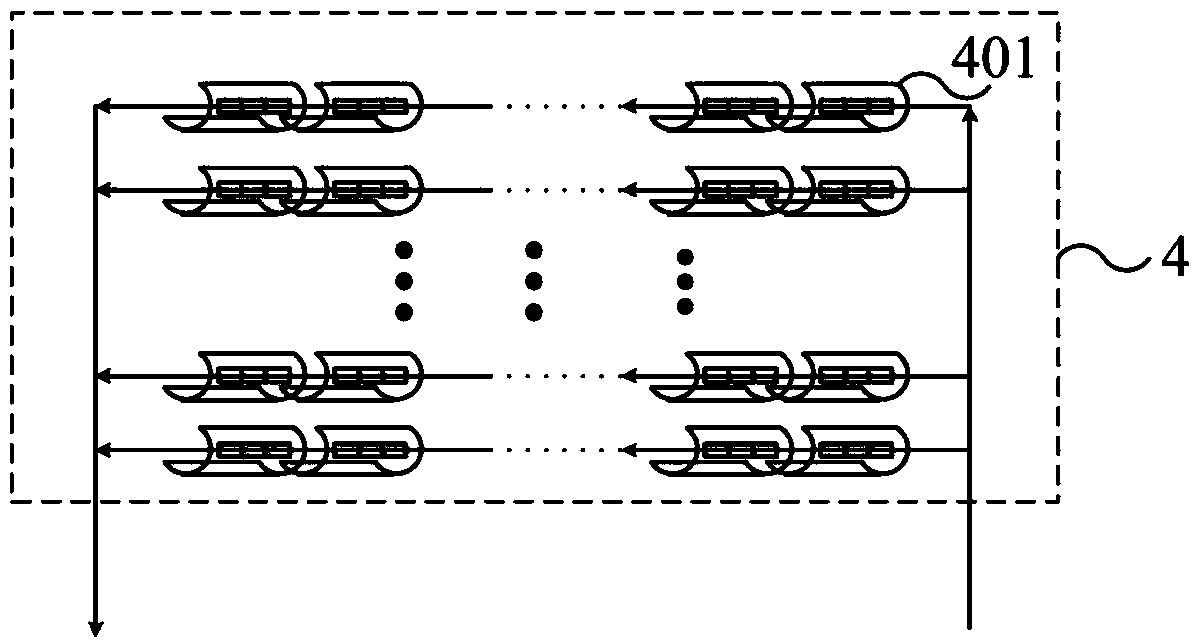

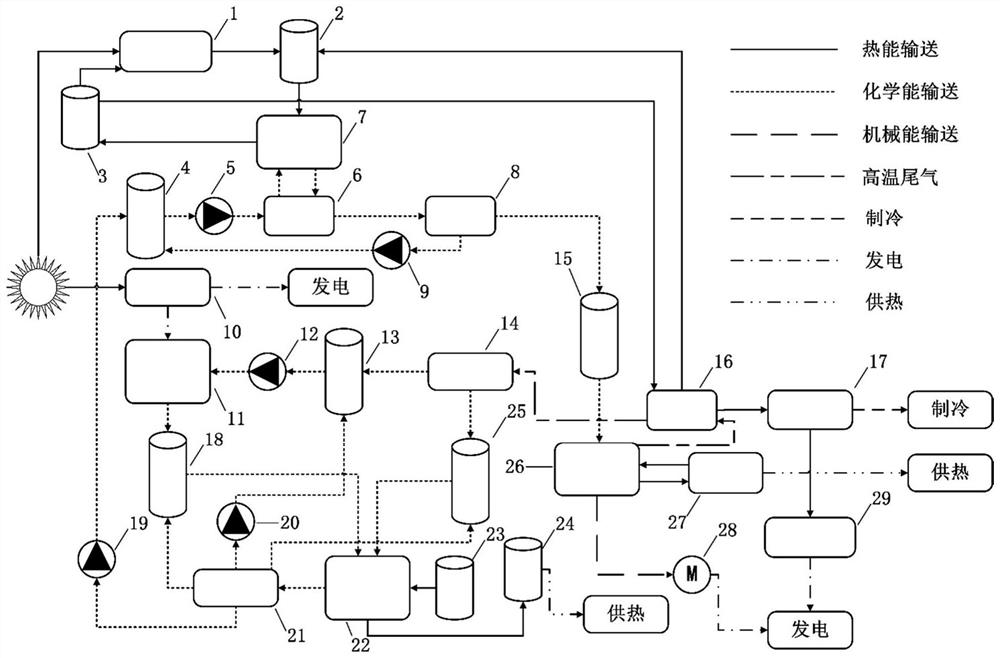

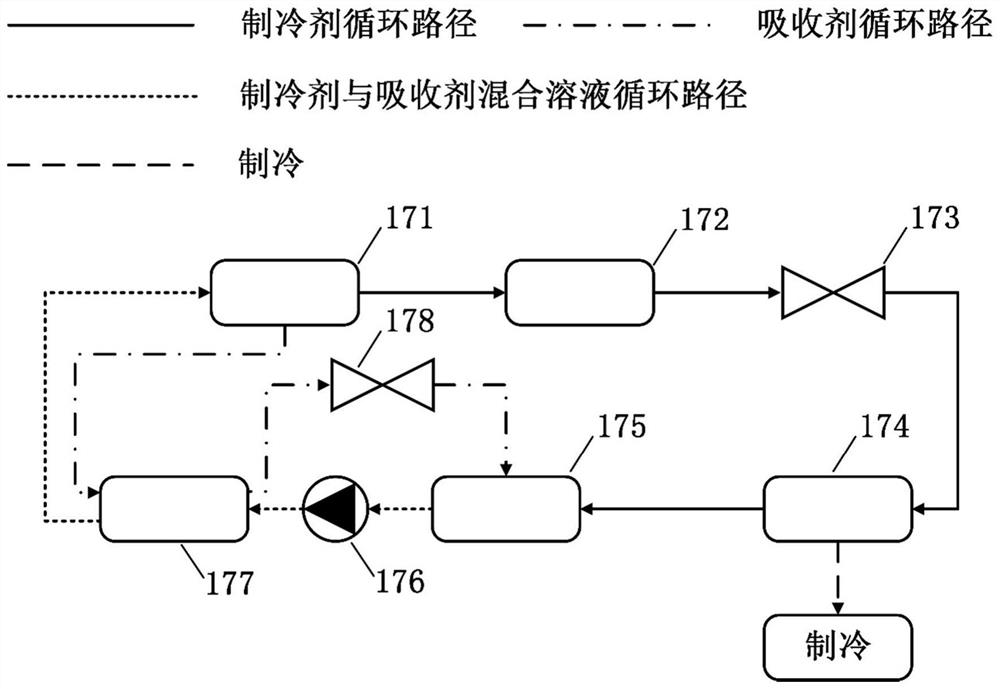

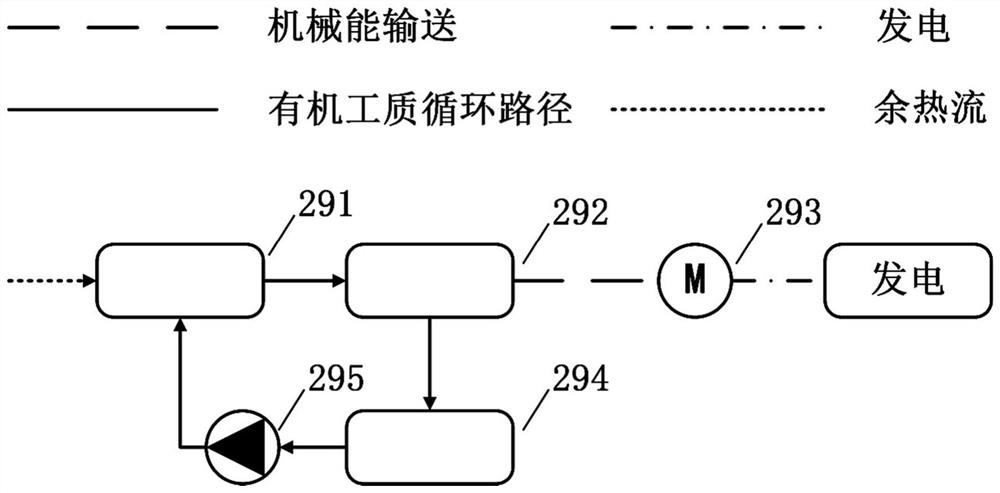

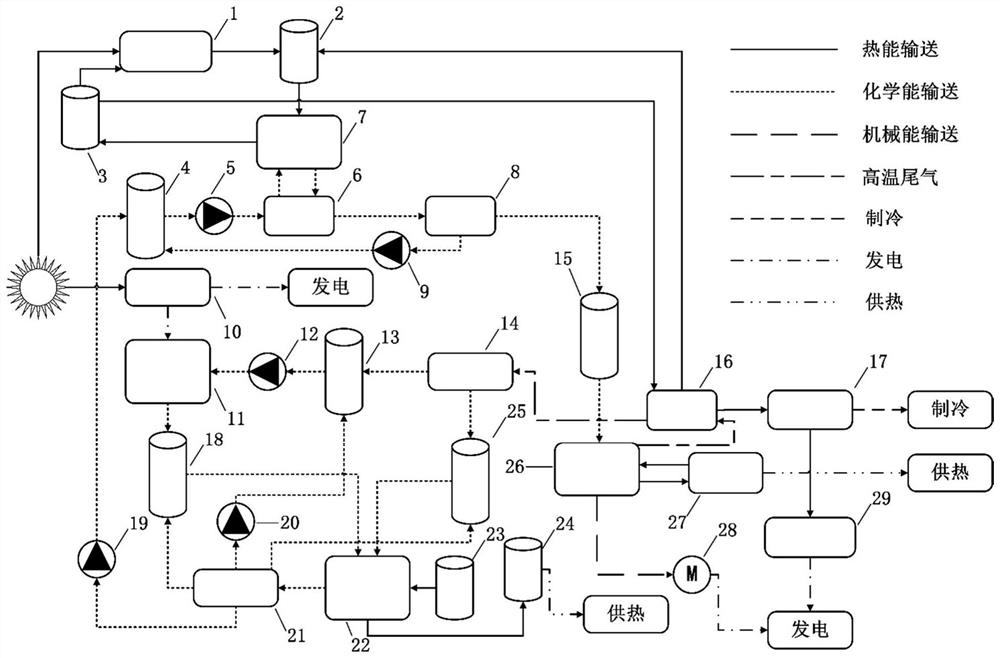

Novel biomass-solar distributed poly-generation system

PendingCN110283623AImprove gasification efficiencyRealize the use of counterpart cascadeInternal combustion piston enginesGaseous fuelsThermochemical reactionProcess engineering

The invention discloses a novel biomass-solar distributed poly-generation system. The system comprises pretreatment equipment, a heat pipe gasification reactor, a solar heat collecting device, purification equipment, a combined cooling heating and power device, a biochar deep processing system and a biomass extract deep processing system; biomass particles pretreated by the pretreatment equipment are conveyed to the heat pipe gasification reactor for a thermochemical reaction; obtained biochar enters the biochar deep processing system; an obtained gaseous product is sent to the purification equipment for purification operation; biomass extract obtained through the purification process is conveyed to the biomass extract deep processing system; purified biomass gas is conveyed to the combined cooling heating and power device. The novel biomass / solar distributed poly-generation system provided by the invention can realize the transformation of biomass to diversified high-value products through the complementary self-adaption of biomass energy and solar energy, and the problem that the energy of the input end of a traditional biomass combined cooling heating and power system is single is effectively solved.

Owner:NANJING FORESTRY UNIV

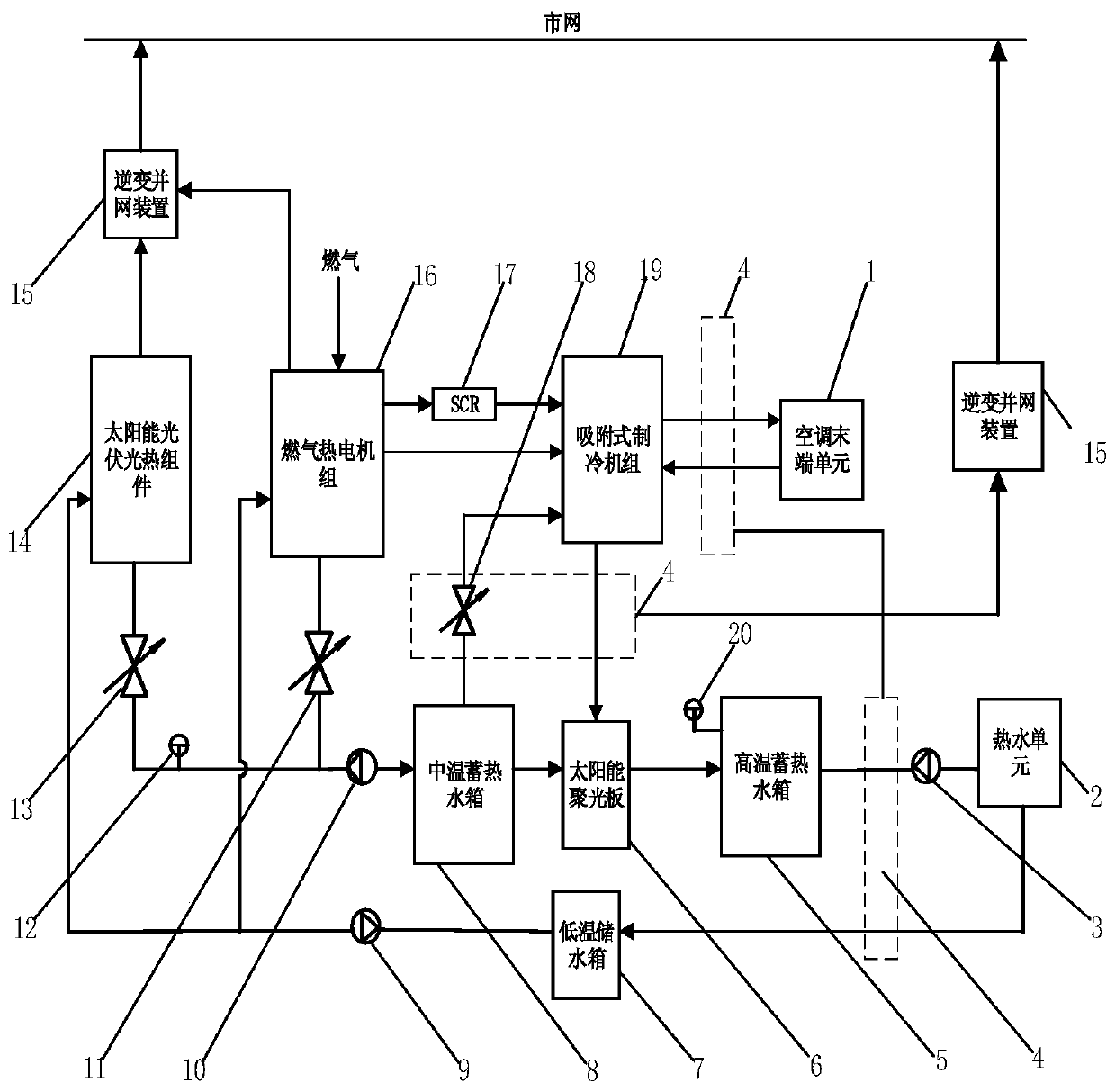

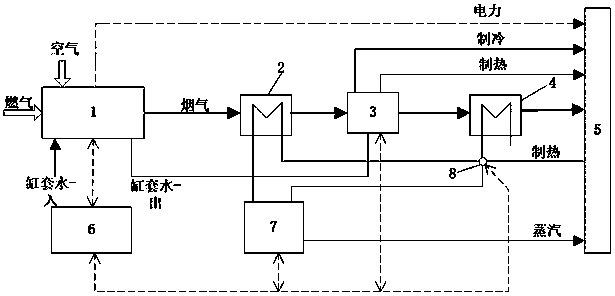

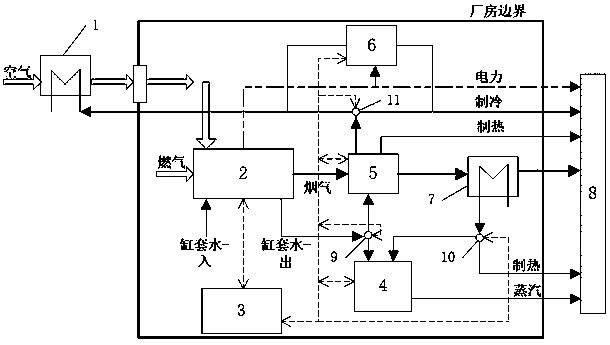

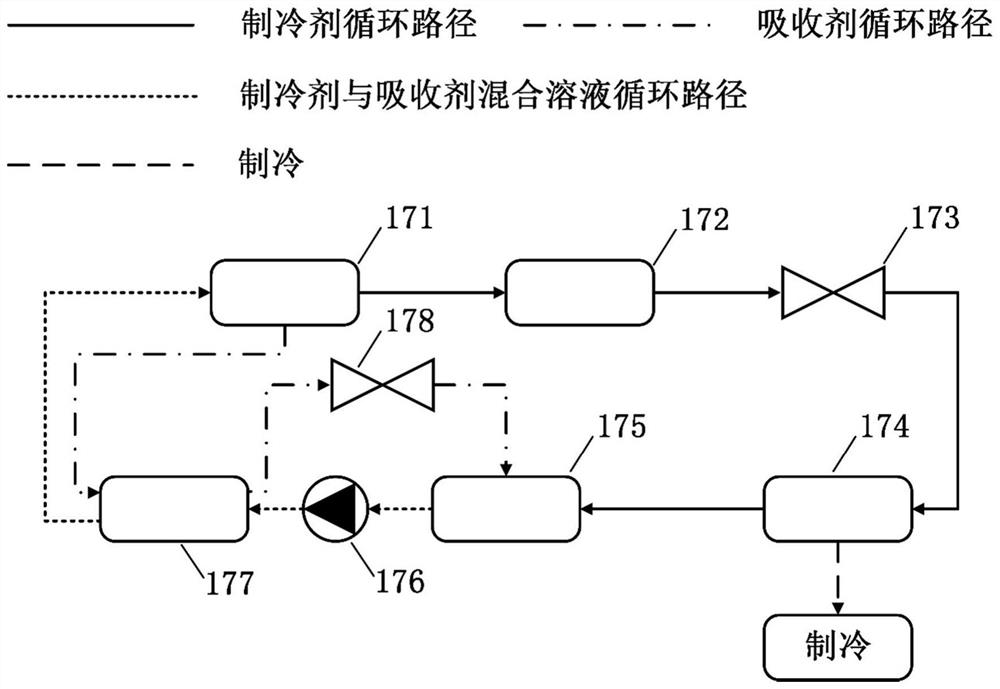

Solar-gas combined triple-generation system with gradient utilization of thermoelectric power generation

PendingCN109990364ARealize heatingRealize the cooling functionSolar heating energyCentral heating with accumulated heatElectricityBusiness efficiency

The invention provides a solar-gas combined triple-generation system with gradient utilization of thermoelectric power generation. The system comprises a solar cooling-heating-electricity triple-generation system, a gas cooling-heating-electricity triple-generation system and a thermoelectric power generation system. According to the solar-gas combined triple-generation system, three functions ofefficient cooling, heating and power generation and combination thereof are achieved mainly through solar heat-collection power generation and gas-thermoelectricity technologies, under the condition of enough solar irradiance, the solar-gas combined triple-generation system is used for heating a room or making hot water by utilizing solar energy as a low-temperature heat source, under the condition of insufficient solar irradiance, the solar-gas combined triple-generation system is used for heating a room or making hot water by utilizing gas as energy, hot water can be made during indoor cooling in summer, and the solar-gas combined triple-generation system can continuously, stably and efficiently operate without limitation of weather; meanwhile, the thermoelectric power generation technology is utilized, waste heat generated in the system operation process is subjected to gradient utilization of energy, and thus the comprehensive energy efficiency ratio of the system is improved.

Owner:TIANJIN CHENGJIAN UNIV

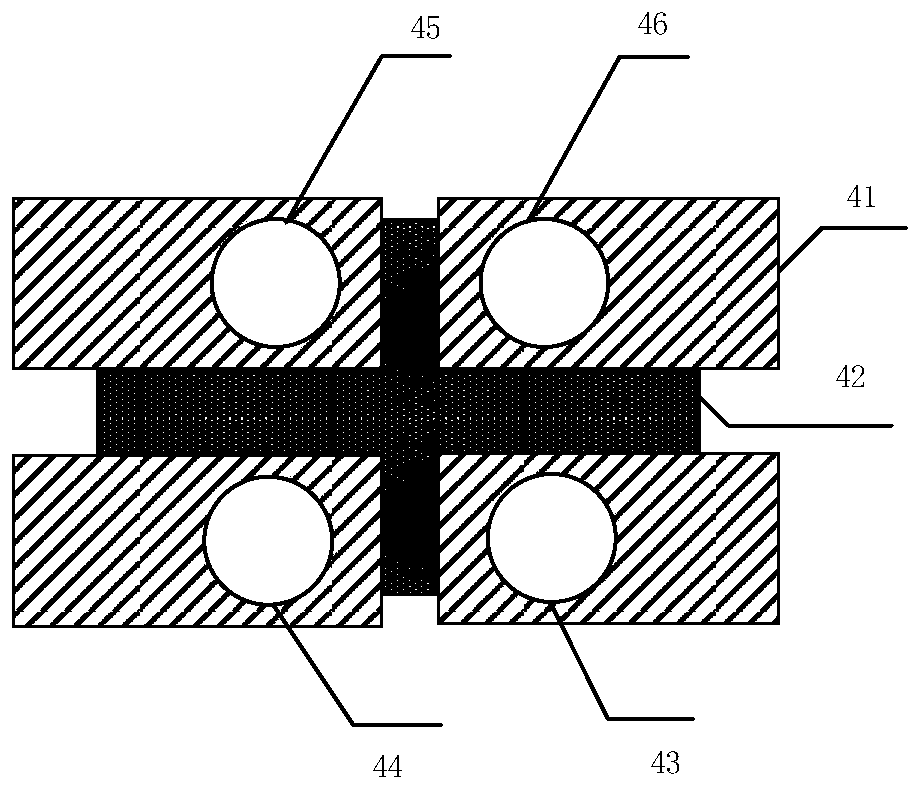

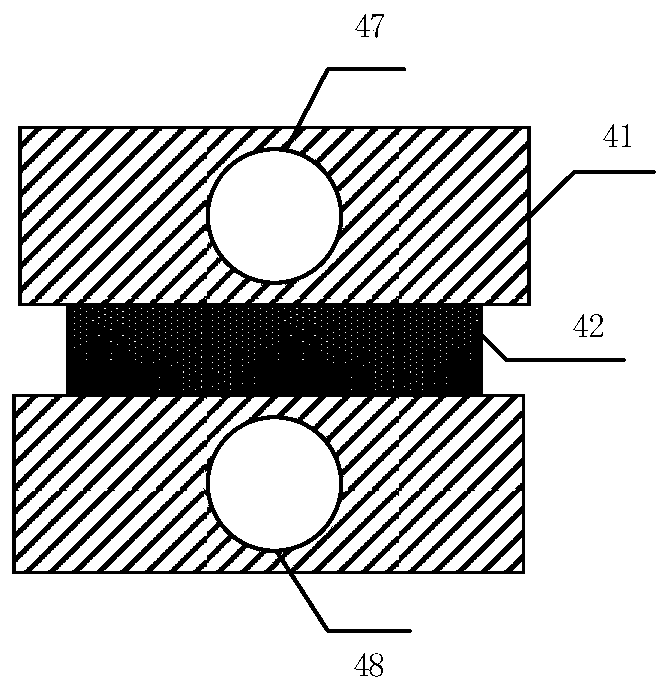

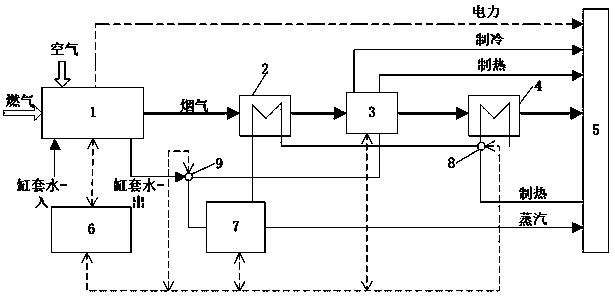

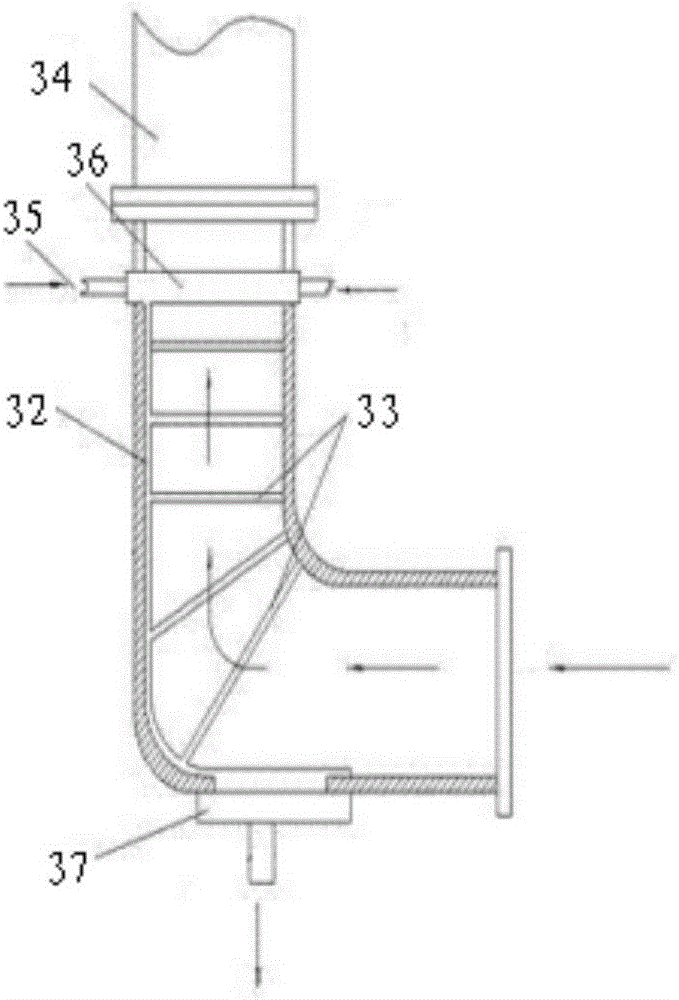

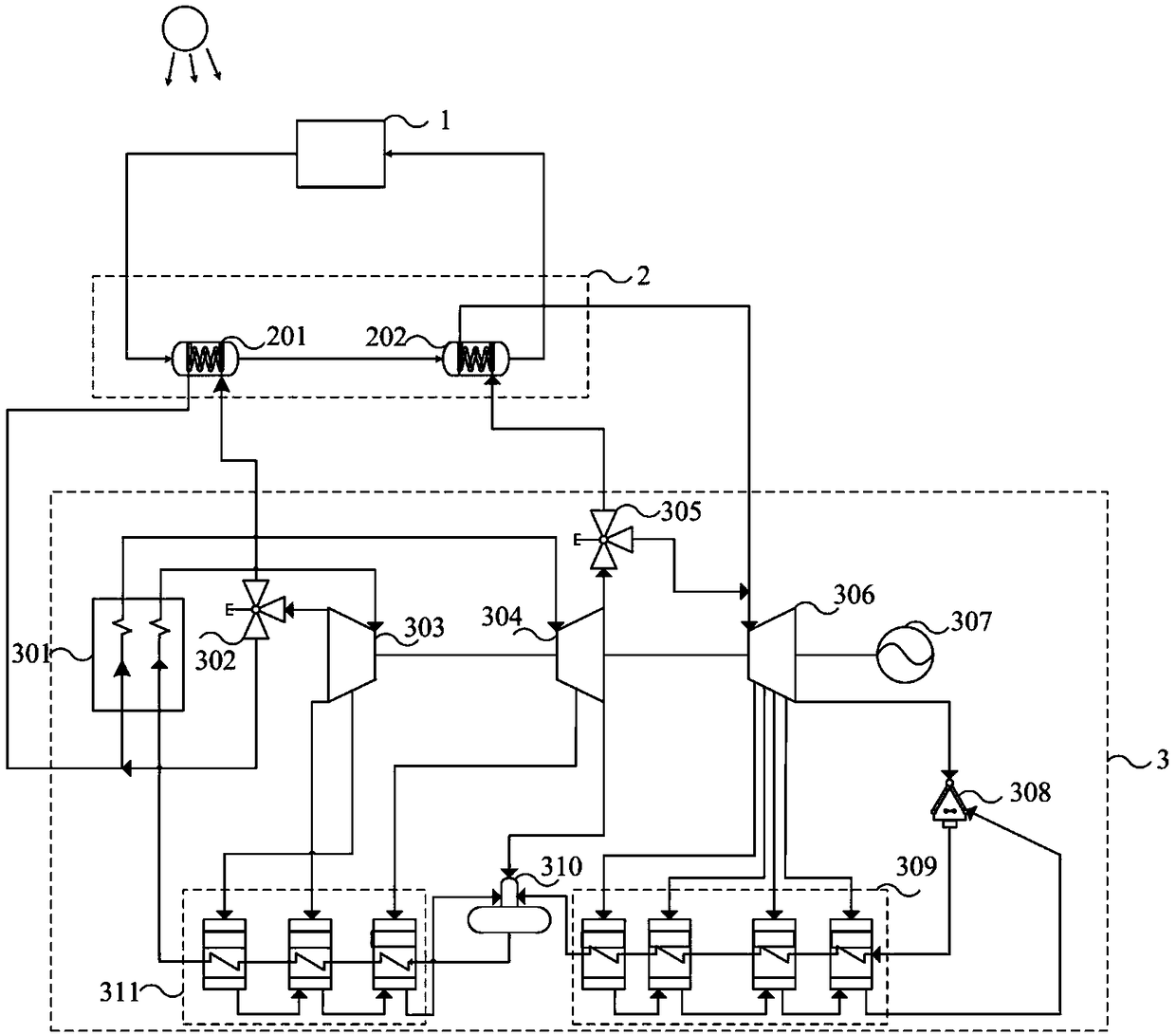

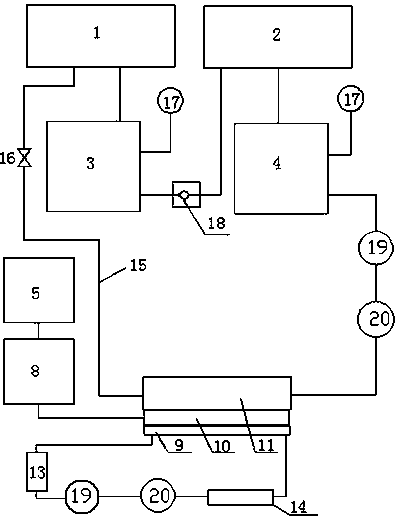

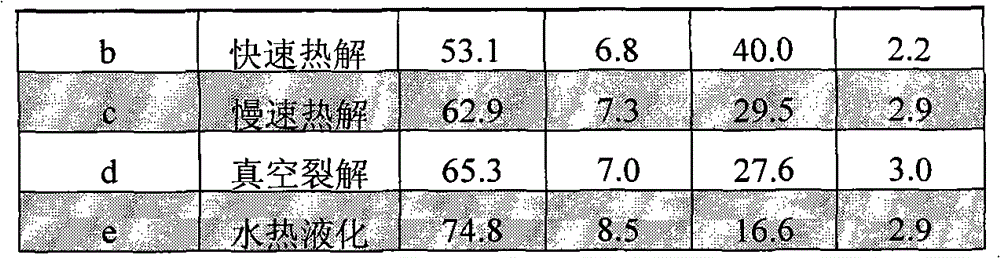

Efficient and flexible interaction distributed energy waste heat utilization system and work method thereof

PendingCN110220210AMaximum absorptionEfficient and flexible adjustmentHeat pumpsEnergy efficient heating/coolingSocial benefitsEconomic benefits

The invention relates to an efficient and flexible interaction distributed energy waste heat utilization system and a work method thereof and aims at solving the supply and demand contradiction between a supply side and a user side and the running problem. The efficient and flexible interaction distributed energy waste heat utilization system comprises a prime motor, a first-stage smoke-water heatexchanger, a lithium bromide unit, a second-stage smoke-water heat exchanger, a regulating system, a heat pump and a hot water distributor. The prime motor, the first-stage smoke-water heat exchanger, the lithium bromide unit and the second-stage smoke-water heat exchanger are sequentially connected, and the prime motor, the lithium bromide unit and the second-stage smoke-water heat exchanger areconnected with the user side. A cylinder jacket water outlet of the prime motor is connected with the lithium bromide unit, the first-stage smoke-water heat exchanger is connected with the heat pump,the first-stage smoke-water heat exchanger and the second-stage smoke-water heat exchanger are connected with the user side through the hot water distributor, and the heat pump is also connected withthe user side. By means of the efficient and flexible interaction distributed energy waste heat utilization system and the work method thereof, on one hand, the distributed energy efficiency is effectively improved, on the other hand, the steam supply problem is solved, and great social benefits and economic benefits are achieved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

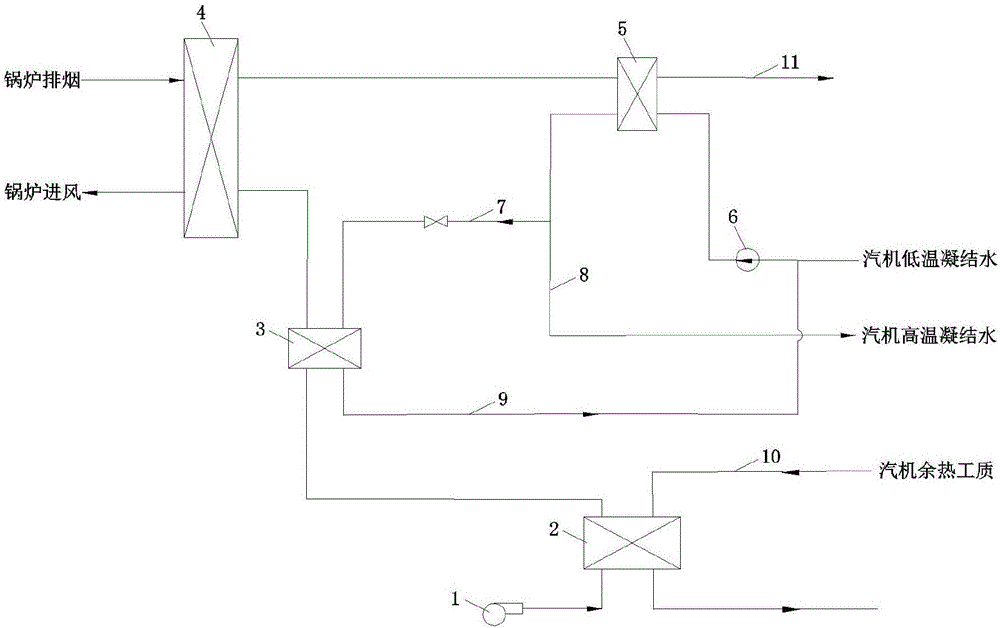

Air cooling unit steam turbine waste heat using system and method

ActiveCN106439899AAchieve waste heatAchieve recyclingCombustion processIndirect carbon-dioxide mitigationCold airEngineering

The invention relates to an air cooling unit steam turbine waste heat using system and method. The system is characterized in that a waste heat working medium in a steam turbine waste heat working medium pipe returns to the steam turbine side after entering a cold air pre-heater (2) to heat boiler cold air; the boiler cold air passes through an air heater to be subject to water condensation through a condensation water pipe (7), is heated again, and then enters an air pre-heater to push out boiler discharge smoke waste heat; and the part of waste heat enters a smoke-water heat exchanger along with smoke to be used for heating steam turbine low temperature condensation water, and a part of heated high temperature condensation water returns to a steam turbine side condensation water system through a condensation water pipe. As the steam turbine waste heat is used for heating the boiler cold air, the outlet smoke temperature of the air pre-heater is improved; and the smoke water heat passes through a smoke-water heat exchanger (5) to be absorbed by the low temperature condensation water, the low temperature condensation water becomes the high temperature condensation water to return to the steam turbine side so as to be used for pushing a high temperature section to carry out steam extraction and acting, and therefore the overall circulation heat efficiency of a unit is improved.

Owner:中国大唐集团科学技术研究总院有限公司

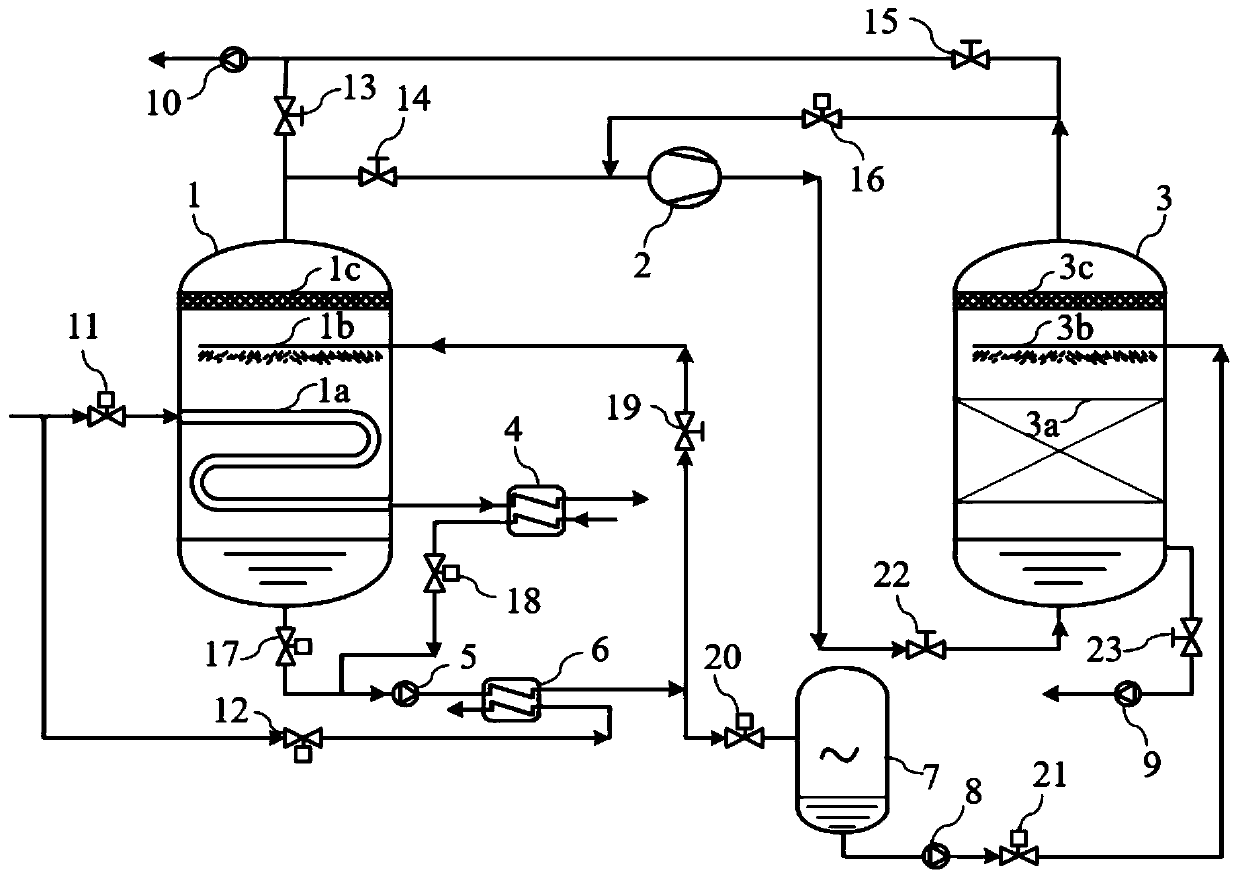

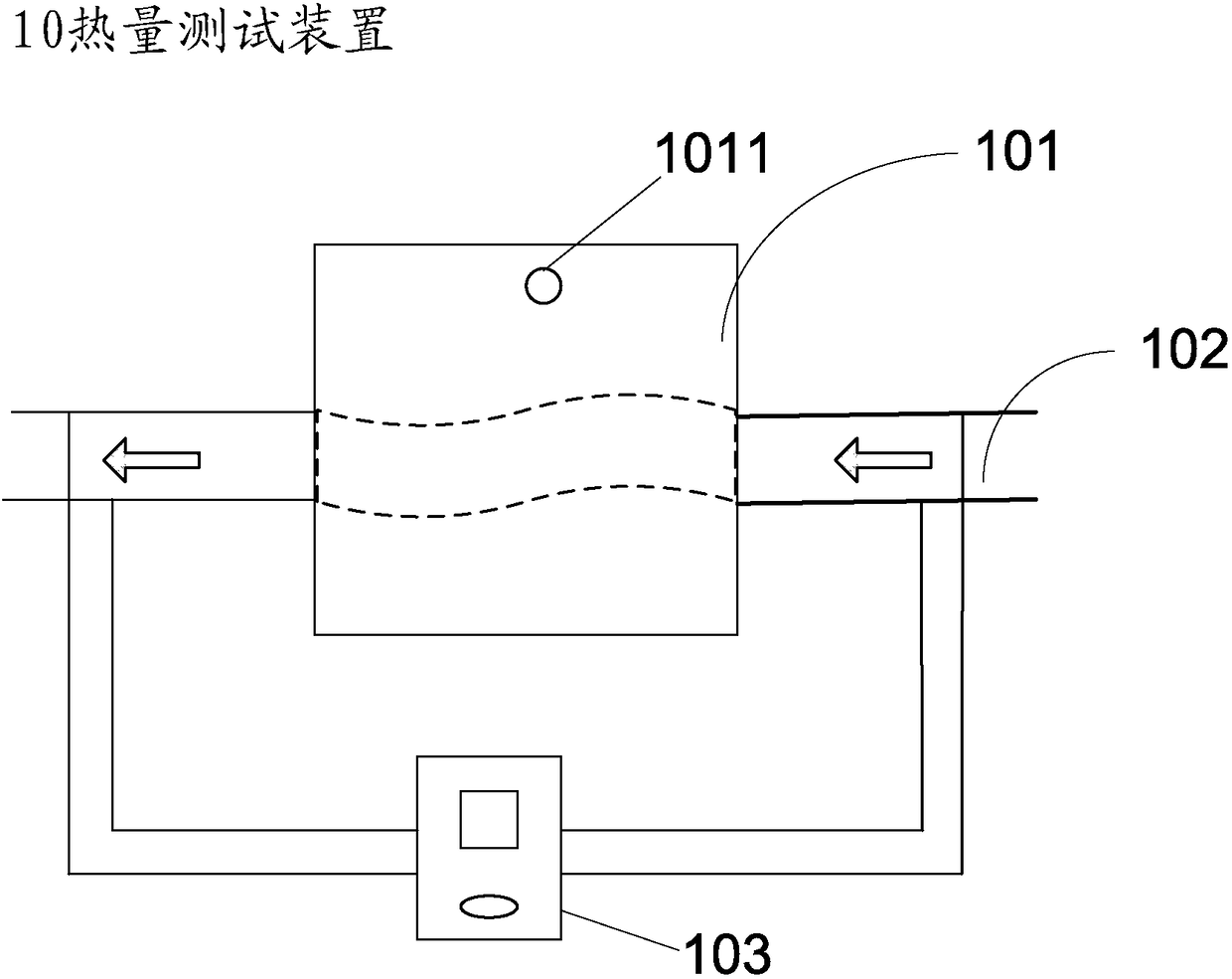

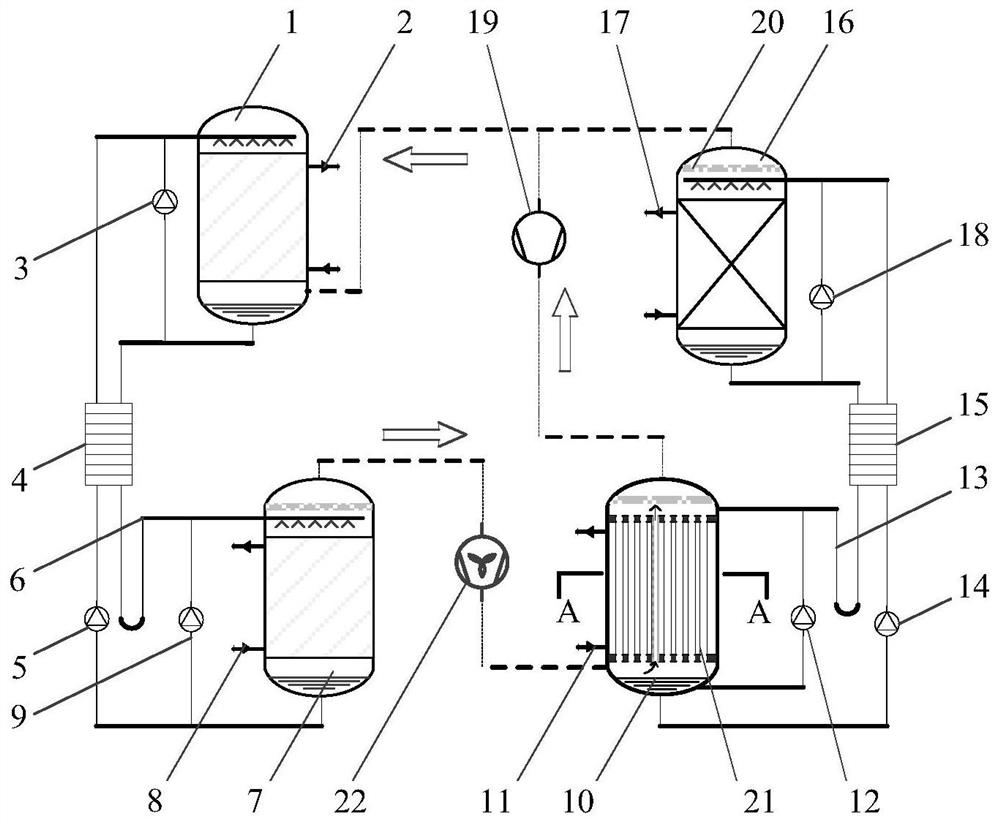

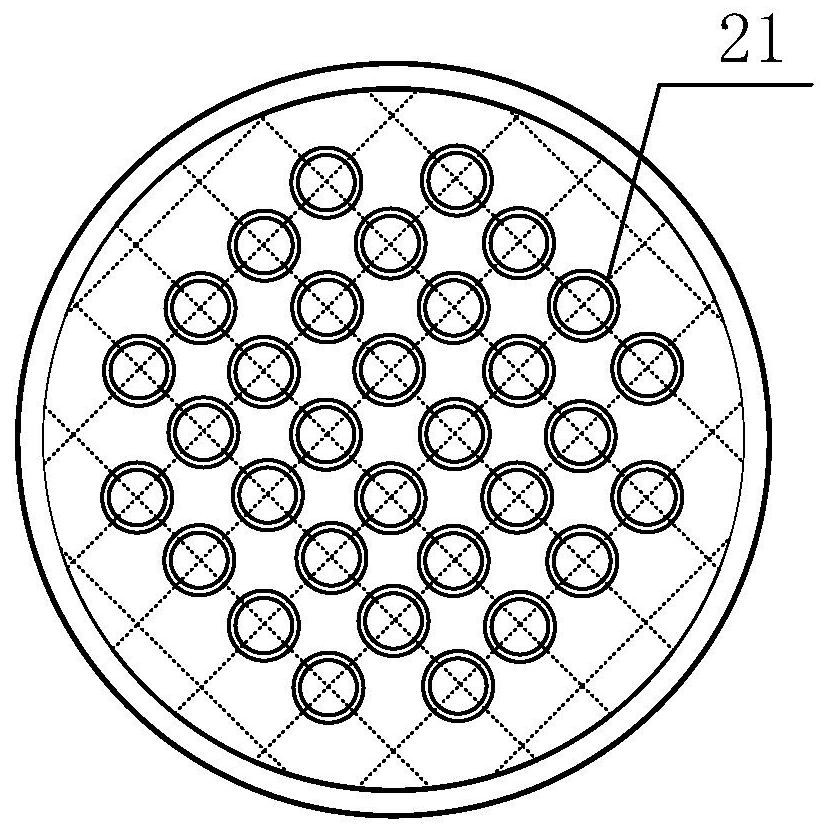

High-temperature heat pump system with water as working medium for industrial wastewater waste heat recovery and control method of high-temperature heat pump system

ActiveCN109798696AControl water temperatureDifferent exhaust pressureMechanical apparatusHeat pumpsWater useWastewater

The invention provides a high-temperature heat pump system with water as a working medium for industrial wastewater waste heat recovery and a method. The high-temperature heat pump system with the water as the working medium for the industrial wastewater waste heat recovery comprises an evaporator, a water steam compressor, a contact type condenser, a first heat exchanger, a second heat exchangerand an electric heating water tank; a steam outlet of the evaporator is connected with an inlet of the water steam compressor, and an outlet of the water steam compressor is connected with a bottom inlet of the contact type condenser; one way of industrial wastewater is connected with a heat exchange tube in the evaporator and flows out after being preheated and supplemented through the first heatexchanger, and the other way of the industrial wastewater is heated and supplemented; and one way of the heated supplemental water is sprayed into the evaporator, and the other way of the heated supplemental water enters the electric heating water tank and then is sprayed into the contact type condenser. The industrial wastewater waste heat recovery heat pump system uses the water as the workingmedium, nontoxicity, environmental protection and high efficiency are achieved, the industrial wastewater waste heat with the temperature above 50 DEG C can be recycled, and high-quality and high-temperature hot water used for living with the temperature above 80 DEG C can be provided.

Owner:JIANGSU UNIV OF SCI & TECH

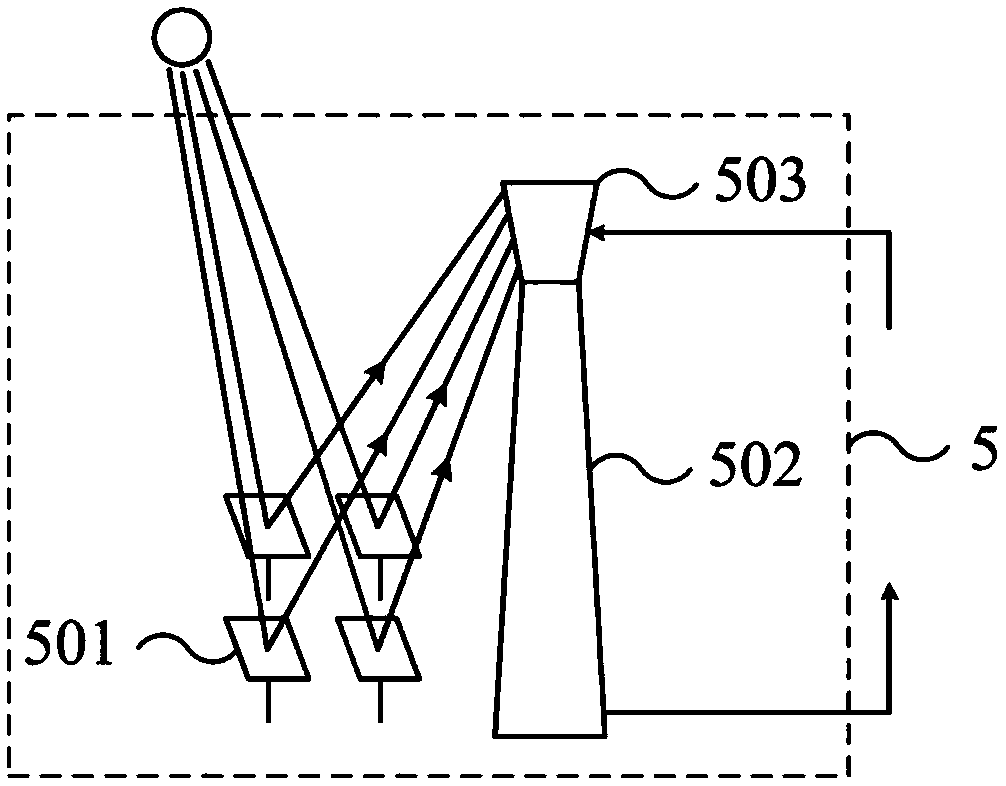

Secondary reheat type solar energy and coal-fired power plant complementary power generation system and operation method

ActiveCN109185085AImprove power generation efficiencyRaise the average endothermic temperatureSolar heating energyFrom solar energyElectricityElectronic systems

The invention discloses a secondary reheat type solar energy and coal-fired power plant complementary power generation system. The secondary reheat type solar energy and coal-fired power plant complementary power generation system comprises a solar heat collection field, a steam heating subsystem and a coal-fired power generation subsystem, wherein a steam conveying pipeline of the coal-fired power generation subsystem is in cooperation connection with the steam heating subsystem, and the steam heating subsystem is in cooperation connection with a high temperature heat exchange fluid conveyingpipeline of the solar heat collection field. The solar heat collection field can conduct secondary reheating on a part of the steam used for the coal-fired power generation subsystem through the steam heating subsystem. The secondary reheat type solar energy and coal-fired power plant complementary power generation system carries out secondary reheating on the coal-fired power generation subsystem through the solar heat collection field and the steam heating subsystem, the average heat absorption temperature of circulating working media in the Rankine cycle of the coal-fired power generationsubsystem is increased, and thus the power generation efficiency of a coal-fired power plant is improved. Meanwhile, the coal-fired power generation subsystem can improve the energy grade and work capacity of solar energy heat introduced into the coal-fired power generation subsystem, and the light-heat conversion efficiency of solar energy and the light-electricity conversion efficiency of the power plant are indirectly improved.

Owner:HUANENG CLEAN ENERGY RES INST

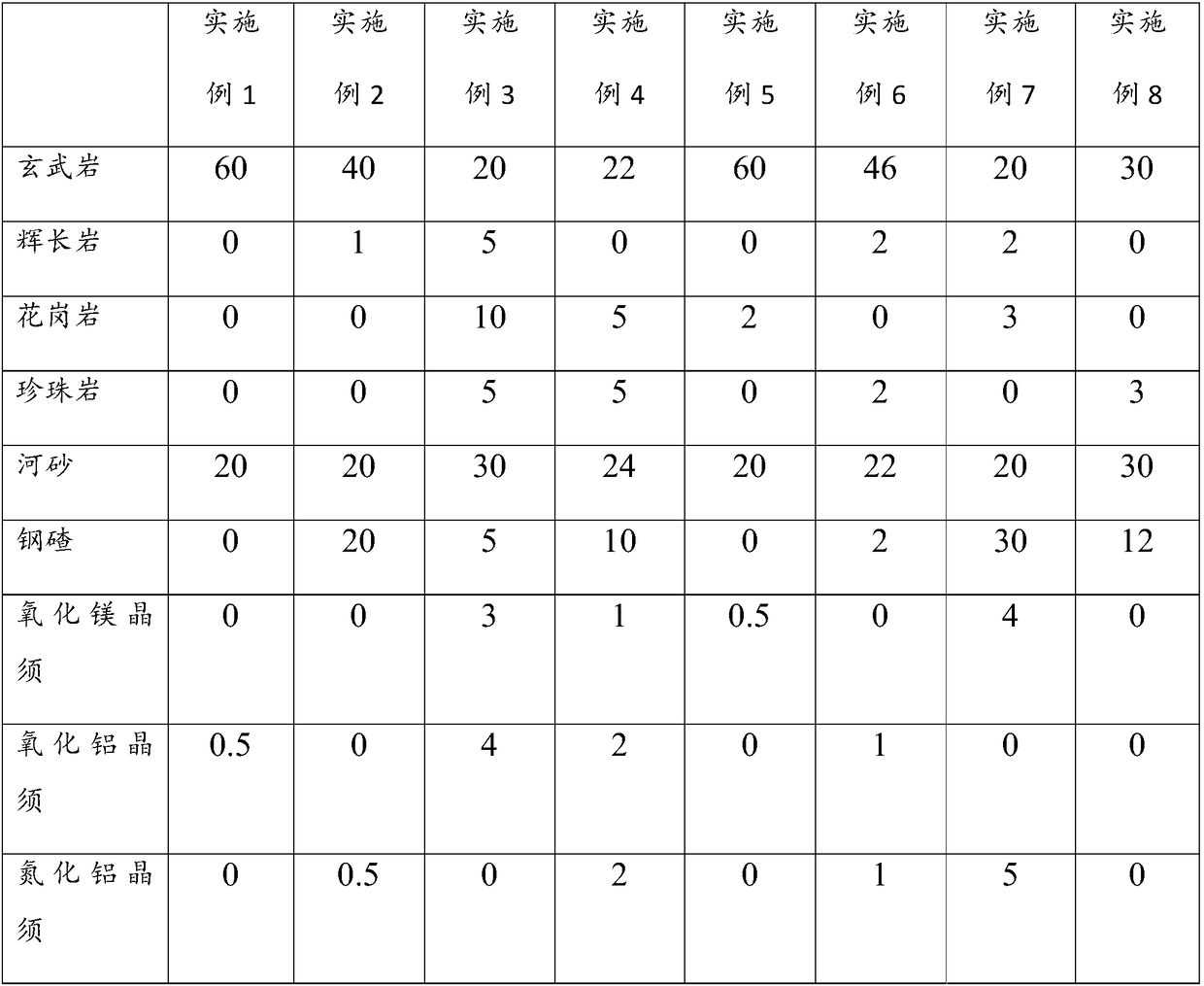

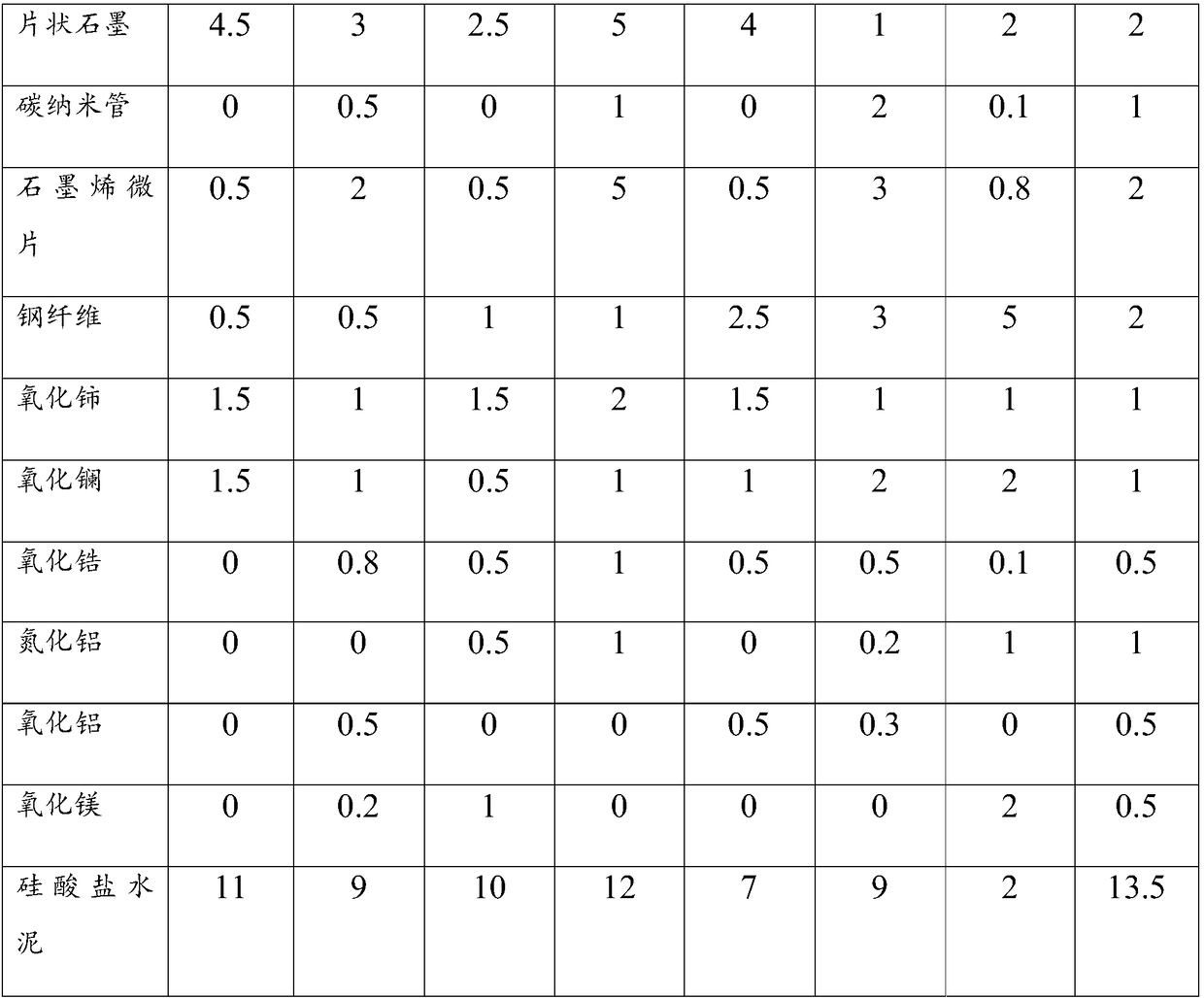

Energy storage composition, its preparation method and its application

The invention discloses an energy storage composition. The energy storage composition comprises the following components in parts by weight: 0.5 to 15 parts of common silicate cement, a rigid crystal material comprising 20 to 60 parts of basalt, 20 to 30 parts of river sand, a heat conduction modifier comprising 1 to 10 parts of graphite, an expansion coefficient modifier comprising 1 to 6 parts of rare earth oxides, and 0.2 to 5 parts of enhancer. The embodiment also provides a preparation method of the energy storage composition. The invention also provides a preparation method and applications of the energy storage composition. A solar energy storage module made of the energy storage composition has the advantages of large energy storage capacity, high energy storage temperature, and low manufacture cost, under the situation that the module strength is guaranteed, and the seasonal high efficient storage of solar energy is realized.

Owner:北京晖丰能源科技有限公司

Method for separating acetic acid from water by acetic acid dehydration tower

ActiveCN102452924BImprove stabilityAvoid direct accessChemical industryCarboxylic compound separation/purificationHigh energyGas phase

The invention relates to a method for separating acetic acid from water by an acetic acid dehydration tower, which mainly solves the problems of high energy consumption and high equipment manufacturing cost in an acetic acid dehydration process in the prior art. In the invention, distillation and dehydration are carried out by pressurizing the acetic acid dehydration tower, water is used as a heat exchange medium in heat pump circulation, the heat released by condensing the discharged material at the top of the acetic acid dehydration tower is absorbed by a heat exchange medium in a closed heat pump process, the heat exchange medium after absorbing the energy of the discharged material at the top of the tower is compressed by a compressor so as to raise temperature, the high-temperature superheated steam is firstly desuperheated by a desuperheater to form saturated steam, and then the saturated steam is transferred into a tower kettle reboiler to carry out heat exchange with the discharged material at the bottom of the tower; and the steam subjected to heat exchange in the tower kettle enters a gas-liquid separation tank after throttling decompression, the separated liquid phase enters a condenser at the top of the tower to carry out heat exchange, and the separated gas phase is mixed with the gas at the outlet of the condenser at the top of the tower to enter the compressor, thereby being used for carrying out heat exchange again with the tower kettle. The technical scheme provided by the invention better solves the problems and can be applied to industrial production for separating acetic acid from water.

Owner:CHINA PETROLEUM & CHEM CORP +1

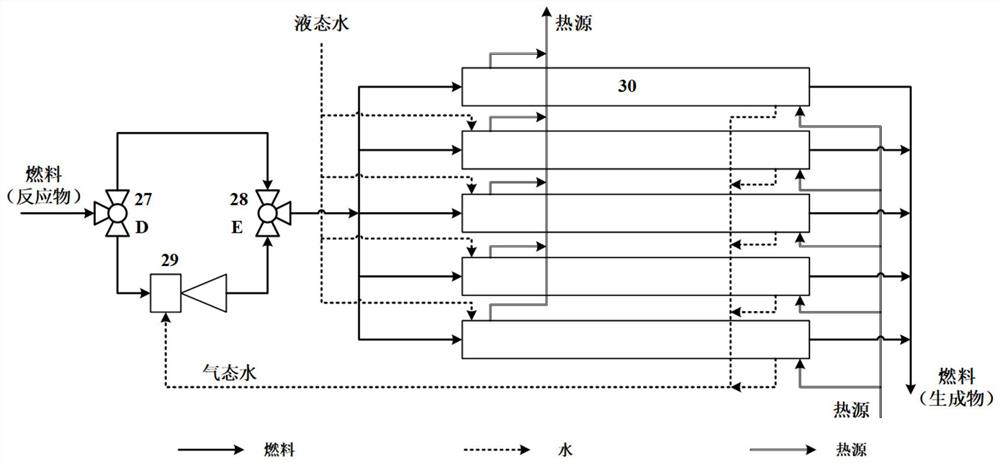

Zero-carbon-emission combined cooling heating and power system based on solar energy methanol decomposition synthesis cycle and method

ActiveCN113530667AAchieving zero emissionsAchieve self-sufficiencySolar heating energyInternal combustion piston enginesOrganic Rankine cycleInternal combustion engine

The invention discloses a zero-carbon-emission combined cooling heating and power system based on solar energy methanol decomposition synthesis cycle and a method, and belongs to the field of distributed energy sources. According to the method, methanol is heated and decomposed by solar energy to obtain carbon monoxide and hydrogen, and low-grade solar energy is converted into high-grade chemical energy to be stored; in an synthesis gas internal combustion engine, carbon monoxide and hydrogen are combusted to generate carbon dioxide and water, a rotating crankshaft drives a generator to generate electric energy to supply power, multi-stage waste heat generated by the system can supply heat, an absorption refrigeration device can supply cold, and low-temperature waste heat can be utilized to generate power through an organic Rankine cycle device; and power is supplied to a load and an electrolytic cell through a photovoltaic device, the electrolytic cell electrolyzes water generated in the synthesis gas internal combustion engine to produce hydrogen, methanol is synthesized again with carbon dioxide generated in the synthesis gas internal combustion engine, and carbon circulation is achieved. The system inputs solar energy and outputs cold and hot electric energy, expensive energy storage equipment is not needed, the energy efficiency is high, and carbon emission is zero.

Owner:ZHEJIANG UNIV

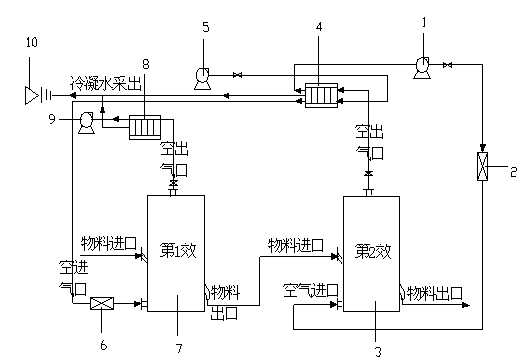

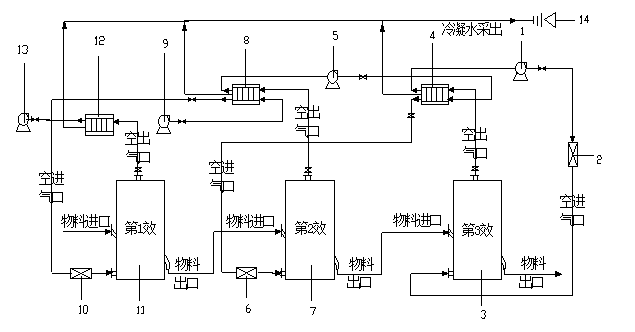

Multiple-effect drying technology

InactiveCN102636014BImprove energy gradeIncrease temperatureDrying gas arrangementsSimulated moving bedProcess engineering

The invention relates to a multiple-effect drying technology which is characterized in that air serves as drying medium and directly contacts with material to be dried to take away moisture and provide heat; multiple stags of drying chambers connected with a heater and a heating device are connected in series to form a simulated moving bed operation mode; air lead out of the last stage is subjected to heat exchange by an air heat exchanger to heat dry medium of the last but one stage; air led out of the last but one stage is subjected to heat exchange by the air heat exchanger to heat the drying medium of the last but two stage; and the rest can be deduced by analogy. The multiple-effect drying technology has the advantages of energy saving and high efficiency, is efficient and quick and is simple to manufacture.

Owner:QINGDAO HAILIN ELECTRONICS MATERIALS TECH

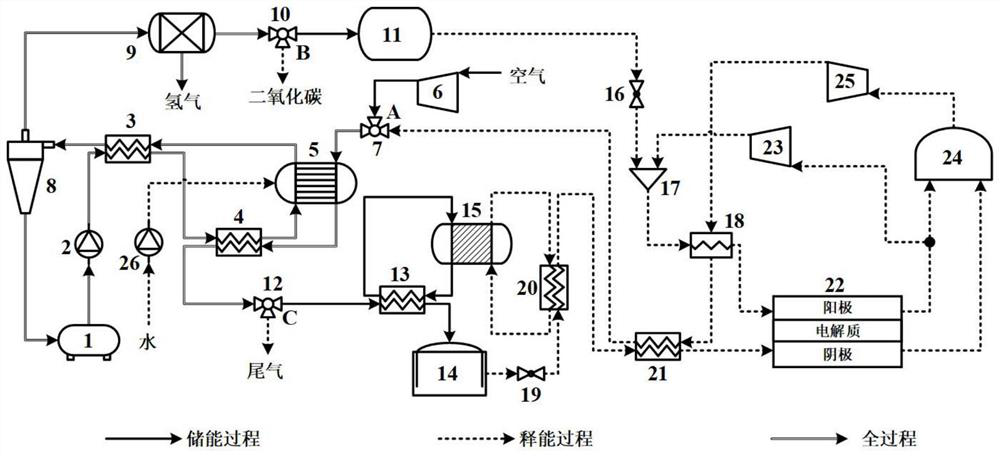

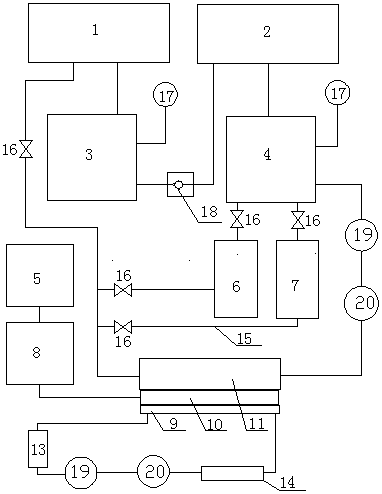

Method and system for integrating compressed air thermochemical process and fuel cell energy storage hydrogen production

ActiveCN113948738AIncrease power generationImprove energy efficiencyFuel cell heat exchangeEnergy inputChemical reactionHeat energy

The invention discloses a method and a system for integrating a compressed air thermochemical process and fuel cell energy storage hydrogen production. In an energy storage stage, compressed air is coupled with a heat absorption type chemical reaction, so that not only is the mixed storage of physical / chemical energy realized, but also the energy grade of compression heat can be improved; in an energy release stage, a solid oxide fuel cell-turbine system matched with compressed air energy storage pressure is adopted, and stored chemical energy and pressure energy are efficiently converted into electric energy; and in the energy storage stage and the energy release stage, hydrogen serves as an energy carrier to achieve conversion from low-grade heat energy to high-grade chemical energy, and the energy utilization efficiency of the system is improved while the energy storage and hydrogen production integrated application mode is achieved.

Owner:XI AN JIAOTONG UNIV

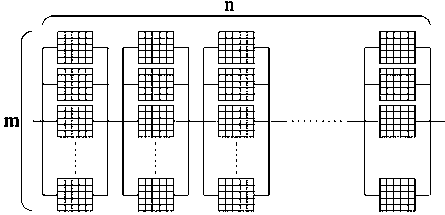

A multi-heat source thermoelectric power generation system

InactiveCN106655894BIncrease output powerImprove conversion efficiencyGenerators/motorsEngineeringTemperature difference

The invention discloses a multi-heat-source thermoelectric power generation system. The multi-heat-source thermoelectric power generation system comprises a multi-heat-source heat collection module, a thermoelectric power generation module and a cooling module, wherein the multi-heat-source heat collection module and the cooling module are connected with the thermoelectric power generation module respectively to form a heat source circuit and a cold source circuit. According to the multi-heat-source thermoelectric power generation system, heat energy in sunlight is collected by using a solar heat collection and thermoelectric power generation technology, the heat energy is stored, and an integrated power generation system of various heat sources is realized through uninterrupted power generation of a thermoelectricity conversion system, so that the system is simple in structure, convenient to dismount and move, wide in application range, stable in operation, long in service and diversified in functions, and is suitable for power generation of various heat sources.

Owner:SHAOYANG UNIV

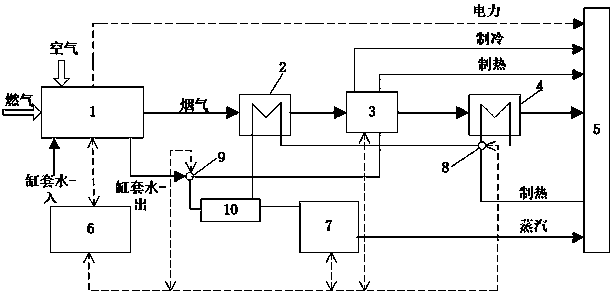

Distributed energy waste heat utilization system and working method thereof

PendingCN110219748AImprove energy gradeGuaranteed adjustment qualityInternal combustion piston enginesClimate change adaptationElectricityFlue gas

The invention relates to a distributed energy waste heat utilization system and a working method thereof. A water-air heat exchanger is connected with a prime motor, the prime motor is connected withthe user side, a flue gas outlet of the prime motor is connected with a lithium bromide unit, a cylinder liner water outlet of the prime motor is connected with a first distributor, the first distributor is connected to a heat pump and the lithium bromide unit, the heat pump is connected to the user side, a flue gas outlet of the lithium bromide unit is connected with a flue gas-water heat exchanger, the flue gas-water heat exchanger is connected with the user side, the flue gas-water heat exchanger is also connected with a second distributor, and the second distributor is connected with the heat pump and the user side; and the lithium bromide unit is connected with the user side, the lithium bromide unit is also connected with a third distributor, the third distributor is connected to theuser side and the water-air heat exchanger, the third distributor is also connected to an electric refrigerator, and the electric refrigerator is connected to the user side. By means of the distributed energy waste heat utilization system and the working method, the distributed energy waste heat quality is effectively improved, and the problem about safety and economical efficiency reduction of aworking condition system in summer is solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

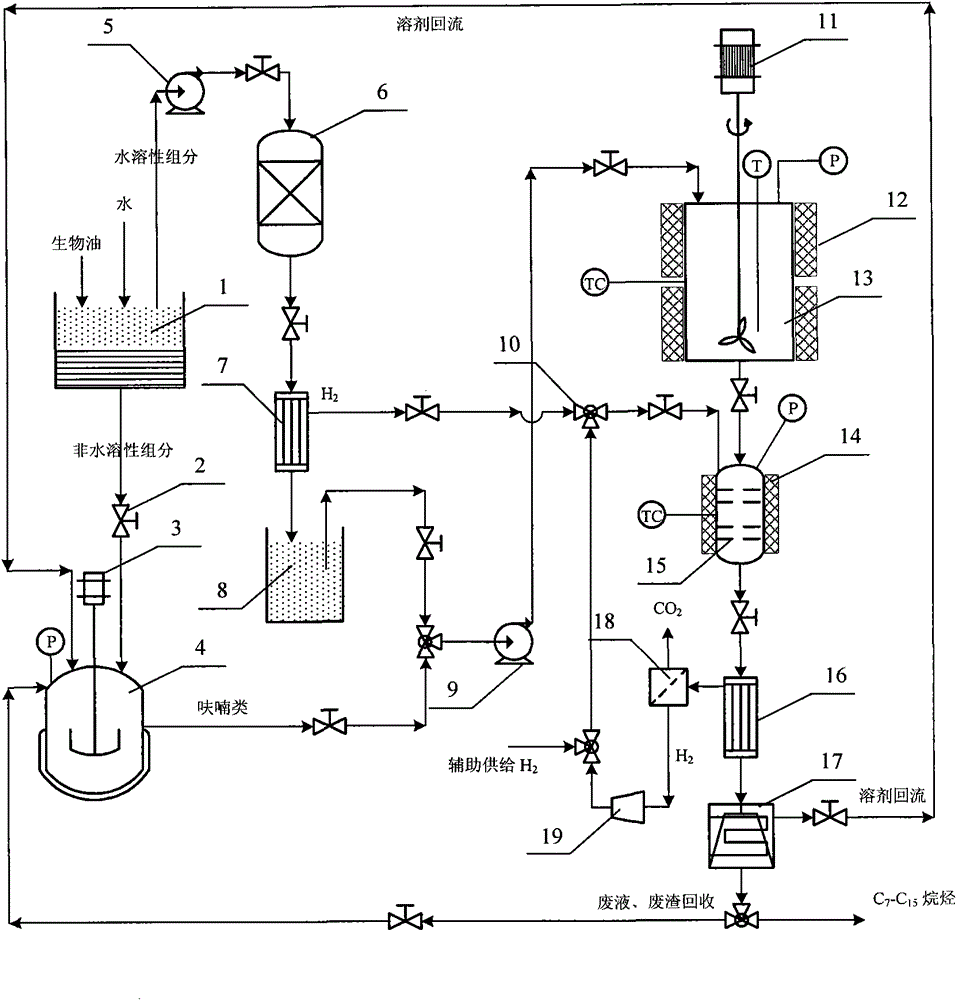

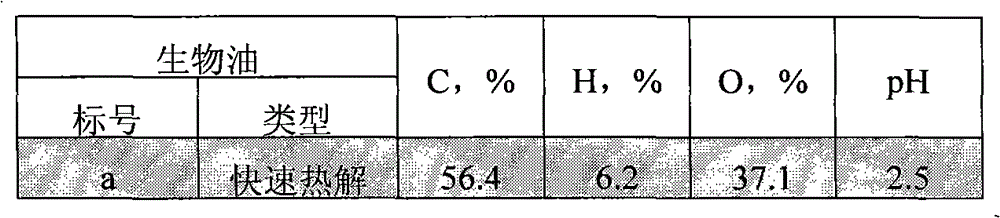

Method for preparing liquid alkane fuel by upgrading bio-oil in aqueous phase catalytic mode

ActiveCN101870881BReduce cokingHigh recovery rateLiquid hydrocarbon mixture productionBio-feedstockAlkaneDesorption

The invention provides a method for preparing liquid alkane fuel by upgrading bio-oil in an aqueous phase catalytic mode. The method comprises the following steps of: 1) pretreating the bio-oil to obtain a water-soluble component and a water-insoluble component; 2) performing a pressurized acid hydrolysis process on a furan compound of the water-insoluble component to prepare the furan compound; 3) performing a reforming and hydrogen production reaction on the water-soluble component; 4) mixing the furan compound with a liquid-phase product separated from the step 3) to perform an aldol condensation reaction to increase carbon chains; and 5) performing a hydrogenation and dehydration reaction on an aldol condensation product to obtain liquid linear alkane. The method has the advantages that: an upgrading process, which is performed in a double-phase system, can effectively contribute to the desorption of an intermediate product from the surface of a catalyst and the mass transfer of an upgraded product, and can reduce the risk of carbon deposition on the surface of the catalyst; the quality of oil obtained by the method is high; the energy density and the energy grade of the bio-oil are improved greatly; and the liquid alkane fuel can be obtained from all kinds of bio-oil so as to partially substitute for the conventional widely-used fossil gasoline and diesel oil fuel.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for separating acetic acid from water by acetic acid dehydration tower

ActiveCN102452924AImprove stabilityAvoid direct accessChemical industryCarboxylic compound separation/purificationHigh energyGas phase

The invention relates to a method for separating acetic acid from water by an acetic acid dehydration tower, which mainly solves the problems of high energy consumption and high equipment manufacturing cost in an acetic acid dehydration process in the prior art. In the invention, distillation and dehydration are carried out by pressurizing the acetic acid dehydration tower, water is used as a heat exchange medium in heat pump circulation, the heat released by condensing the discharged material at the top of the acetic acid dehydration tower is absorbed by a heat exchange medium in a closed heat pump process, the heat exchange medium after absorbing the energy of the discharged material at the top of the tower is compressed by a compressor so as to raise temperature, the high-temperature superheated steam is firstly desuperheated by a desuperheater to form saturated steam, and then the saturated steam is transferred into a tower kettle reboiler to carry out heat exchange with the discharged material at the bottom of the tower; and the steam subjected to heat exchange in the tower kettle enters a gas-liquid separation tank after throttling decompression, the separated liquid phase enters a condenser at the top of the tower to carry out heat exchange, and the separated gas phase is mixed with the gas at the outlet of the condenser at the top of the tower to enter the compressor, thereby being used for carrying out heat exchange again with the tower kettle. The technical scheme provided by the invention better solves the problems and can be applied to industrial production for separating acetic acid from water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Test method and device for half cell of fluid bed electrode direct carbon fuel cell

InactiveCN102004225BHigh activitySimple structureFuel cell auxillariesElectrical testingElectrical batteryReaction temperature

The invention provides a test method and device for half cell of fluid bed electrode direct carbon fuel cell. The method comprises the following steps: firstly, arranging a current collector and the mixture of carbon fuel and catalyst granules in a half cell; secondly, fixing a porous plate in a preset position, and sequentially adding an auxiliary electrode, a reference electrode and carbonate; then, introducing nitrogen gas into the half cell, heating the nitrogen gas to a preset reaction temperature, regulating the flow of the nitrogen gas, and introducing oxygen gas and carbon dioxide into the reference electrode to balance the gas; and finally, connecting to an external circuit to start experiment. The device for realizing the testing method is a half-cell reaction device and comprises a half-cell reactor and a gas preheater, two electric heating devices are respectively used for carrying out temperature control on the half-cell reactor and the gas preheater, and a rotatable support structure is used for supporting and fixing the half-cell reaction device and the electric heating devices and realizing the dumpage of molten carbonate in the half cell. By making full use of theadvantages of the fluid bed electrode and the direct carbon fuel cell, the performance of the cell can be improved.

Owner:SOUTHEAST UNIV

Selective absorption-compression composite heat pump circulating device and method based on chemical reaction

ActiveCN112254372AGood thermal effectImprove the coefficient of performanceMechanical apparatusClimate change adaptationChemistryExothermic reaction

The invention discloses a selective absorption-compression composite heat pump circulating device and method based on a chemical reaction. The device is mainly composed of an exothermic reactor, a heat absorption reactor, an absorber, a generator, a compressor, a Roots blower, a solution heat exchanger and the like. According to the device, a gas cycle working medium is used for synthetic reactionin the exothermic reactor to heat heating medium water, and a synthetic reactant is used for decomposition reaction in the heat absorption reactor to absorb low-grade heat energy; and mixed gas generated by decomposition is subjected to primary pressure boosting through the Roots blower and then separated through absorption, selective absorption gas is subjected to secondary pressure boosting through thermal compression, and absorbed residual gas leaves from the upper part of the absorber, enters the compressor to increase pressure and enters the reactor to form circulation. According to thedevice and the method, compression is carried out to required working pressure after selective absorption, electric compression and thermal compression are combined for use, the main driving energy islow-grade heat energy driving, and the primary energy utilization rate of the system is improved.

Owner:SOUTHEAST UNIV

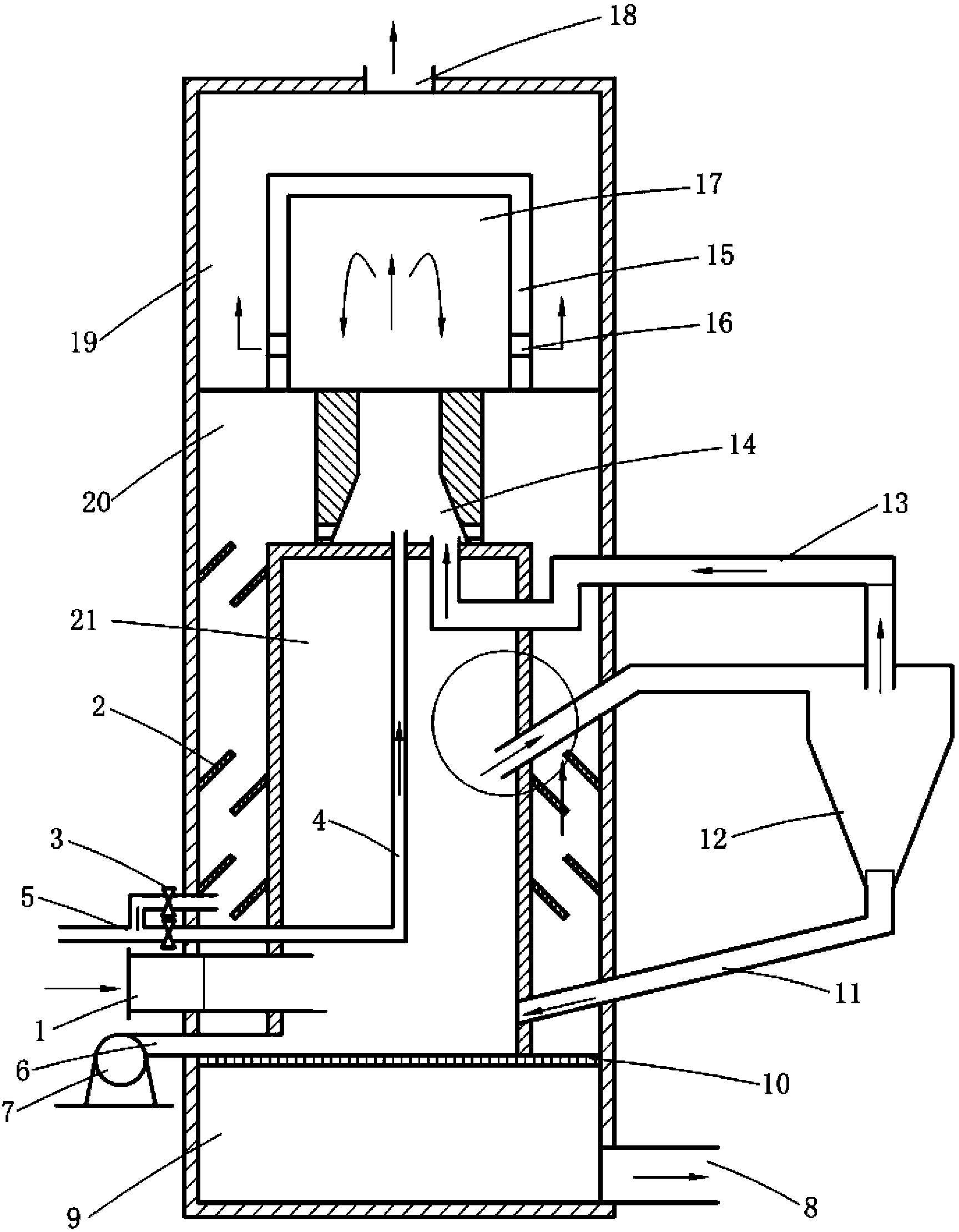

Biomass fuel boiler

ActiveCN102777890BRealize Cyclone CombustionImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberSlag

Owner:HEFEI UNIV OF TECH

Zero-carbon emission cogeneration system and method based on solar methanol decomposition synthesis cycle

ActiveCN113530667BAchieving zero emissionsAchieve self-sufficiencySolar heating energyInternal combustion piston enginesElectrolysisOrganic Rankine cycle

Owner:ZHEJIANG UNIV

Method for separating acetic acid and water

ActiveCN102452926BIncrease the heat exchange areaReduce dosageCarboxylic compound separation/purificationAcetic acidState of art

The invention relates to a method for separating acetic acid and water, mainly solving the problems in the prior art that the energy consumption is high in acetic acid dehydrating process and equipment manufacturing cost is high. The technical scheme of the method is as follows: rectifying and dehydrating by adding pressure to an acetic acid dehydrating tower; using water as a heat-transfer medium during a heat pump cycle; absorbing heat released from condensation on materials discharged from the acetic acid dehydrating tower top by the heat-transfer medium in a closed heat pump flow; compressing the heat-transfer medium having absorbed the energy of the materials discharged from the tower top by a compressing machine, wherein the temperature of the medium is raised then; desuperheating the high temperature superheated steam by a desuperheating device to form saturated steam, and filling the steam in a tower kettle reboiler to exchange heat with the discharged materials from the tower bottom. The method with the above technical scheme better solves the problems in the prior art, and can be applied in industrial production for separating acetic acid and water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com