Absorption and hydration coupling device and method for separating ethylene and ethane in catalytic cracking dry gas or ethylene pyrolysis gas

An ethylene cracking and catalytic cracking technology, applied in the ethane combined plant, chemical industry, and ethylene fields, can solve the problems of low concentration separation, such as uneconomical economy, and achieve high efficiency separation, improved purity and yield, and reduced energy grade. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

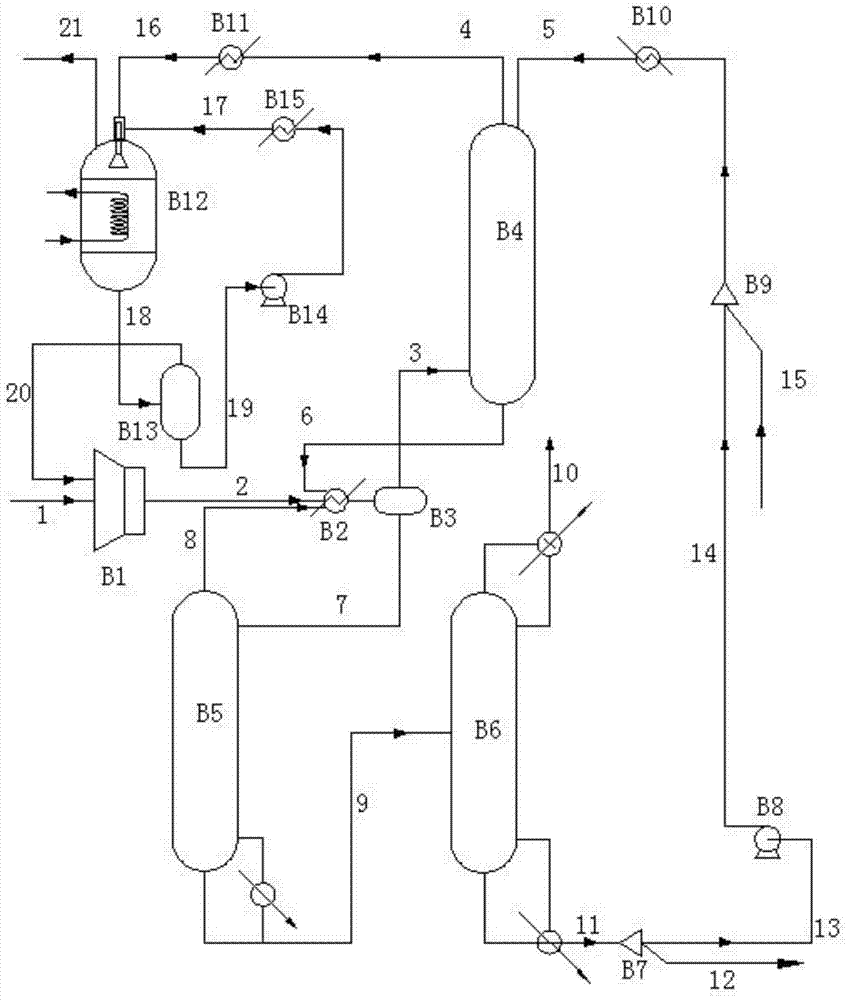

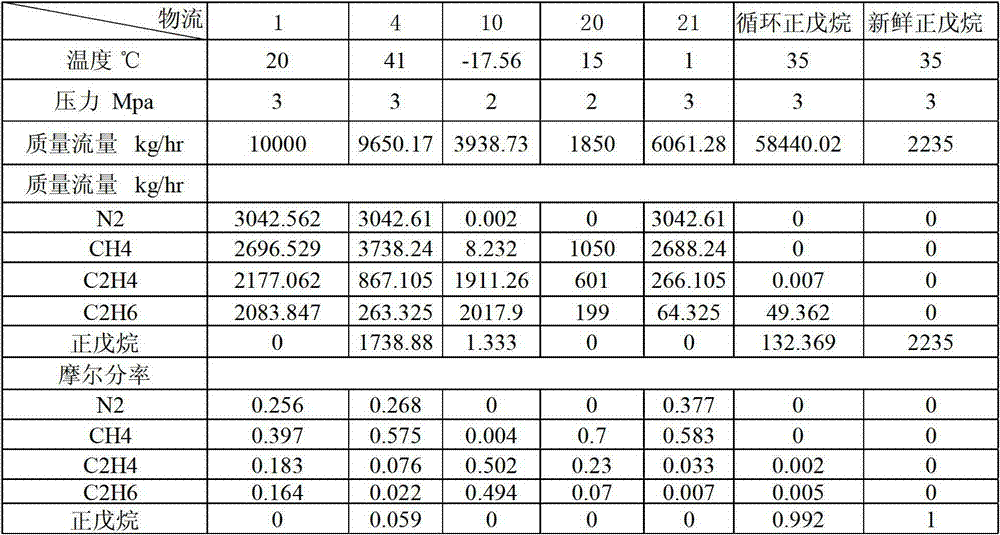

[0029] The molar composition of the feed gas is 25.64%N2+39.68%CH4+18.32%C2H4+16.36%C2H6, the mass flow rate is 10000kg / h, and the feed temperature is 20℃. In the absorption process, the circulating amount of n-pentane used by the absorbent is 46605kg / h, and 1894kg / h of n-pentane is supplemented per hour. Pure water is used in the hydration separation process, and the gas-liquid ratio is 140:1 under standard conditions.

[0030] The heat exchanger B2 heats the streams 2, 6, and 8 to 35°C. The temperature of the balance tank B3 is 35℃ and the pressure is 3MPa. The absorption tower B4 is operated at 3MPa, 10 trays, an intermediate condenser is set between the 3rd and 4th trays, the liquid phase temperature is set to 35℃, and the temperature of the top absorbent It is 35°C. The desorption tower B5 has an operating pressure of 3MPa and a bottom temperature of 143.6°C. An intermediate reboiler is set between the 5th and 6th trays with a temperature of 85°C and a pressure of 3MPa. A...

Embodiment 2

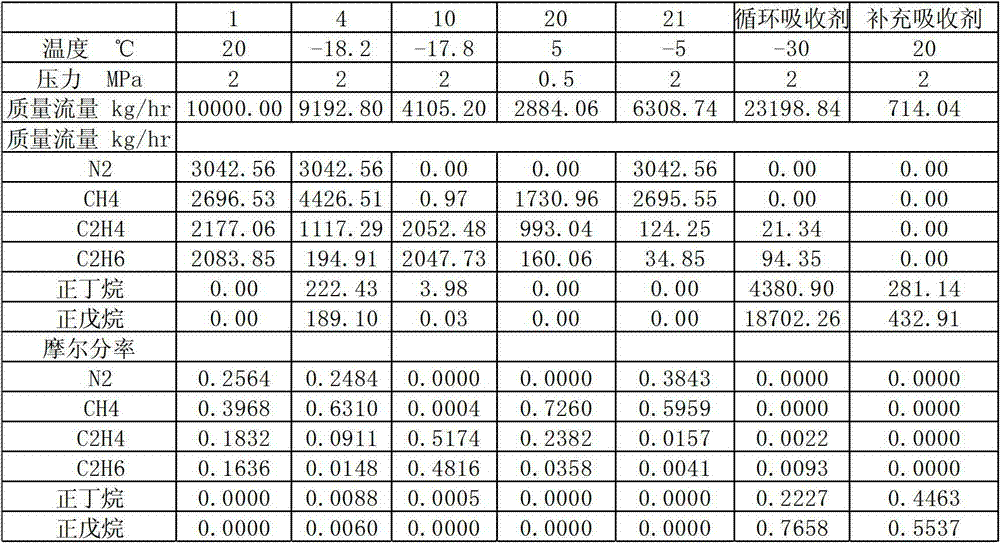

[0035] The molar composition of the feed gas is 25.64%N2+39.68%CH4+18.32%C2H4+16.36%C2H6, the mass flow rate is 10000kg / h, and the feed temperature is 20℃. In the absorption process, a mixed solvent of n-butane and n-pentane is used as the absorbent, and the circulation amount is 23198.84 kg / h, supplemented with n-butane 281.14 kg / h, and supplemented with n-pentane 432.91 kg / h. Pure water is used in the hydration separation process, and the gas-liquid ratio is 140:1 under standard conditions.

[0036] The heat exchanger B2 heats the streams 2, 6, and 8 to -30°C. The temperature of the balance tank B3 is -30℃ and the pressure is 2MPa. The absorption tower B4 is operated at 2MPa, with 10 trays, an intermediate condenser is set between the 3rd and 4th trays, the liquid phase temperature is set to -30℃, and the top absorption The temperature of the agent is -30°C. The desorption tower B5 has an operating pressure of 2MPa and a bottom temperature of 49.2°C. Absorbent regeneration t...

Embodiment 3

[0041] The molar composition of the feed gas is 25.64%N2+39.68%CH4+18.32%C2H4+16.36%C2H6, the mass flow rate is 10000kg / h, and the feed temperature is 20℃. In the absorption process, a mixed solvent of n-butane and n-pentane is used as the absorbent. The circulation amount is 24348.69 kg / h, supplemented with n-butane 328.16 kg / h, and supplemented with n-pentane 603.73 kg / h. Pure water is used in the hydration separation process, and the gas-liquid ratio is 140:1 under standard conditions.

[0042] The heat exchanger B2 heats the streams 2, 6, and 8 to 0°C. The temperature of the balance tank B3 is 0℃ and the pressure is 4MPa. The absorption tower B4 is operated at 4MPa, 10 trays, an intermediate condenser is set between the 3rd and 4th trays, the liquid phase temperature is set to 0℃, and the temperature of the top absorbent It is 0°C. The desorption tower B5 has an operating pressure of 4MPa and a bottom temperature of 118.3°C. Absorbent regeneration tower B6 has an operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com