Water source heat pump and sludge anaerobic assimilation integration method and system

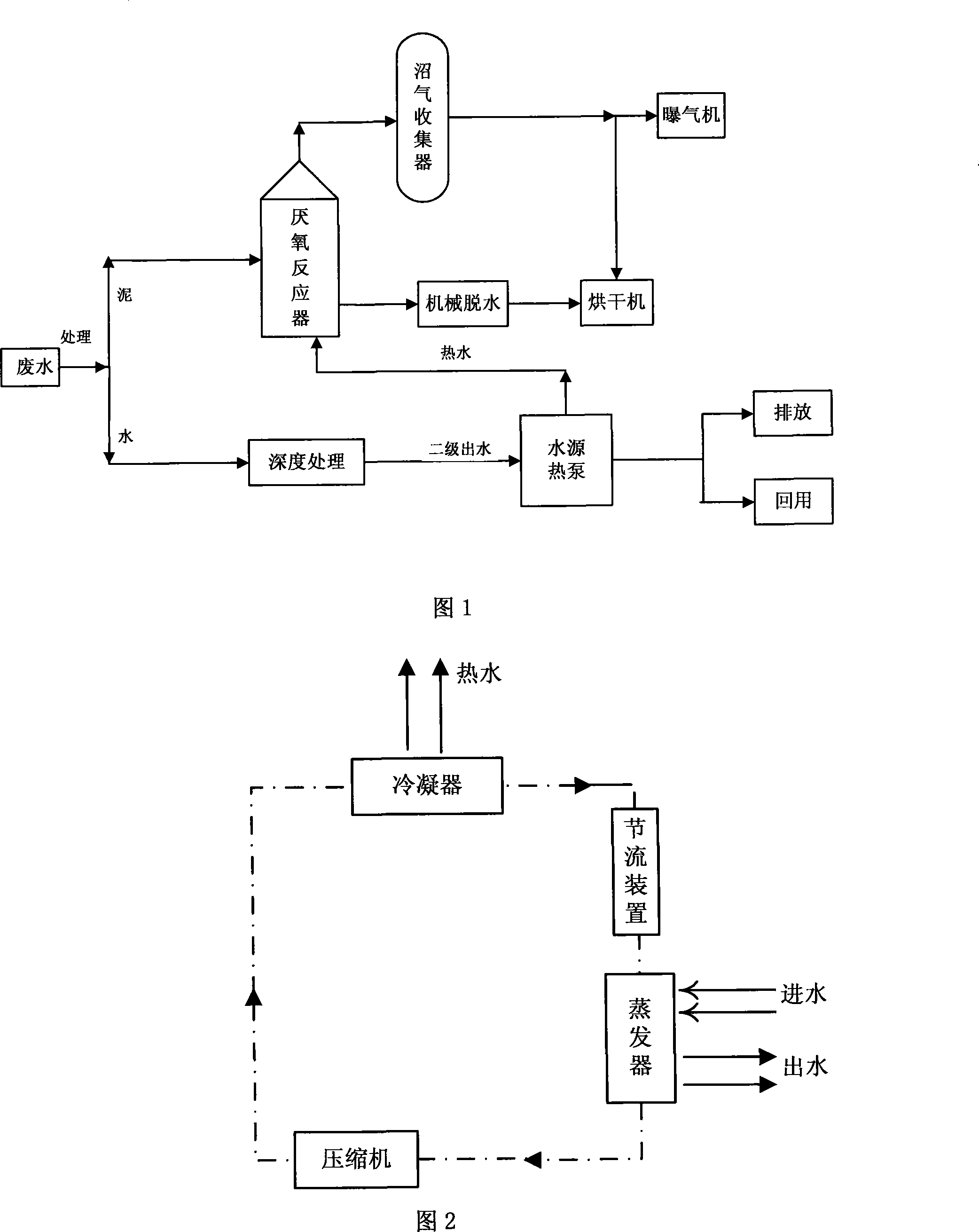

A water source heat pump, anaerobic digestion technology, applied in heat recovery system, dehydration/drying/concentrated sludge treatment, heat pump and other directions, can solve the problems of high cost application, low efficiency of normal temperature sludge anaerobic digestion, etc., to achieve no pollution Environment, energy saving, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A sewage treatment plant with a scale of 10,000t / d produces about 36m of sludge with a water content of 96% 3 , the secondary effluent temperature is 18°C, and the heat required for anaerobic digestion of sludge at medium temperature (about 35°C) is 3.024×10 6 kJ, the heat that the heat pump can extract from the secondary effluent is 140×10 6 kJ (assuming that the water temperature is lowered by 5°C), assuming that the conversion efficiency of the heat pump to provide energy for sludge digestion is 80%, it can be seen from the above data that the heat generated by the heat pump absorbing waste heat from sewage can far meet the needs of sludge anaerobic digestion heat. At the same time, the biogas generated by the anaerobic digestion of the remaining sludge can be used to dry the sludge and / or drive the aeration blower.

[0026] Existing data show that the power consumption of urban sewage treatment plants accounts for about 60% to 90% of the total energy consumption, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com