Method for separating acetic acid from water

A technology of acetic acid dehydration and acetic acid aqueous solution, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of high operating costs and high energy consumption of acetic acid dehydration, reduce operating costs, improve device operation stability, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

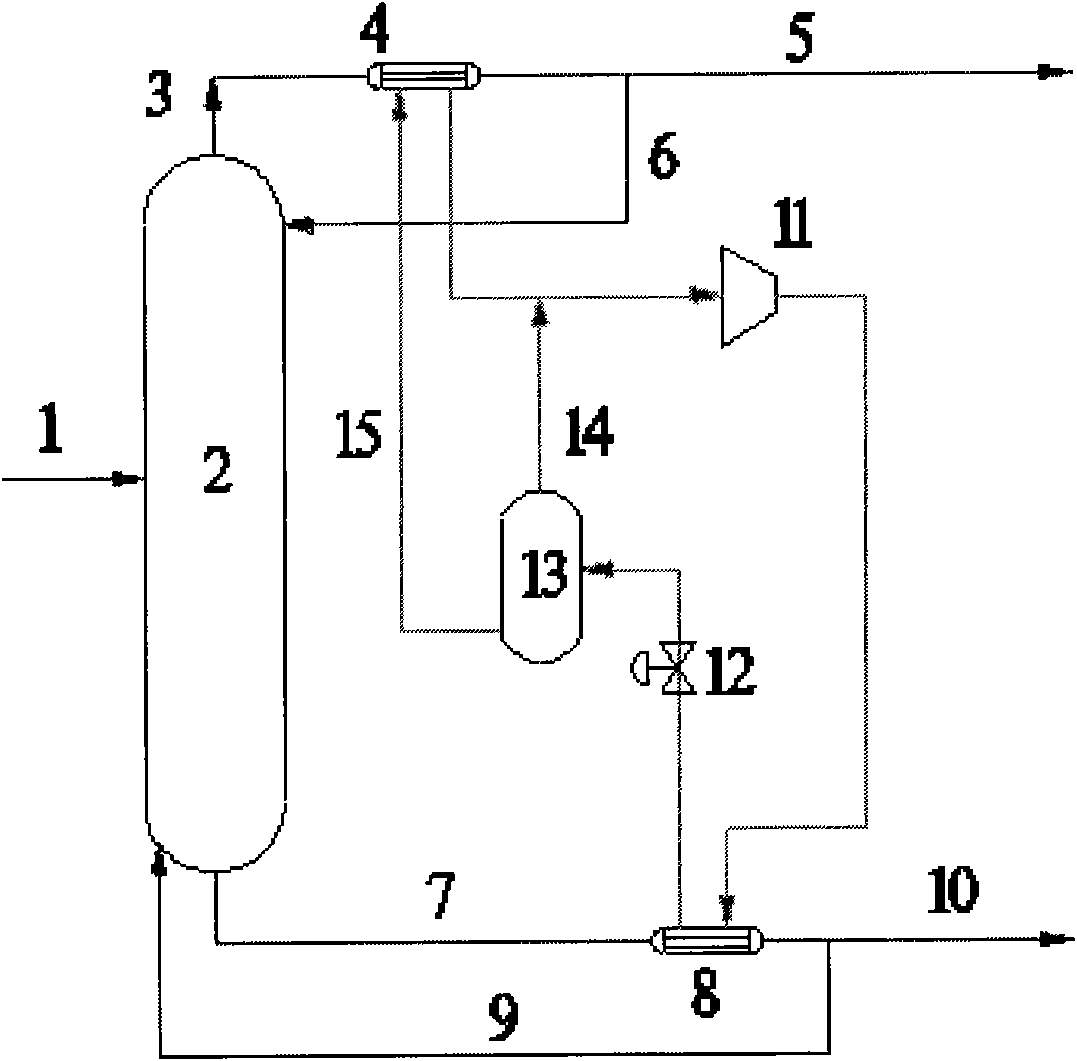

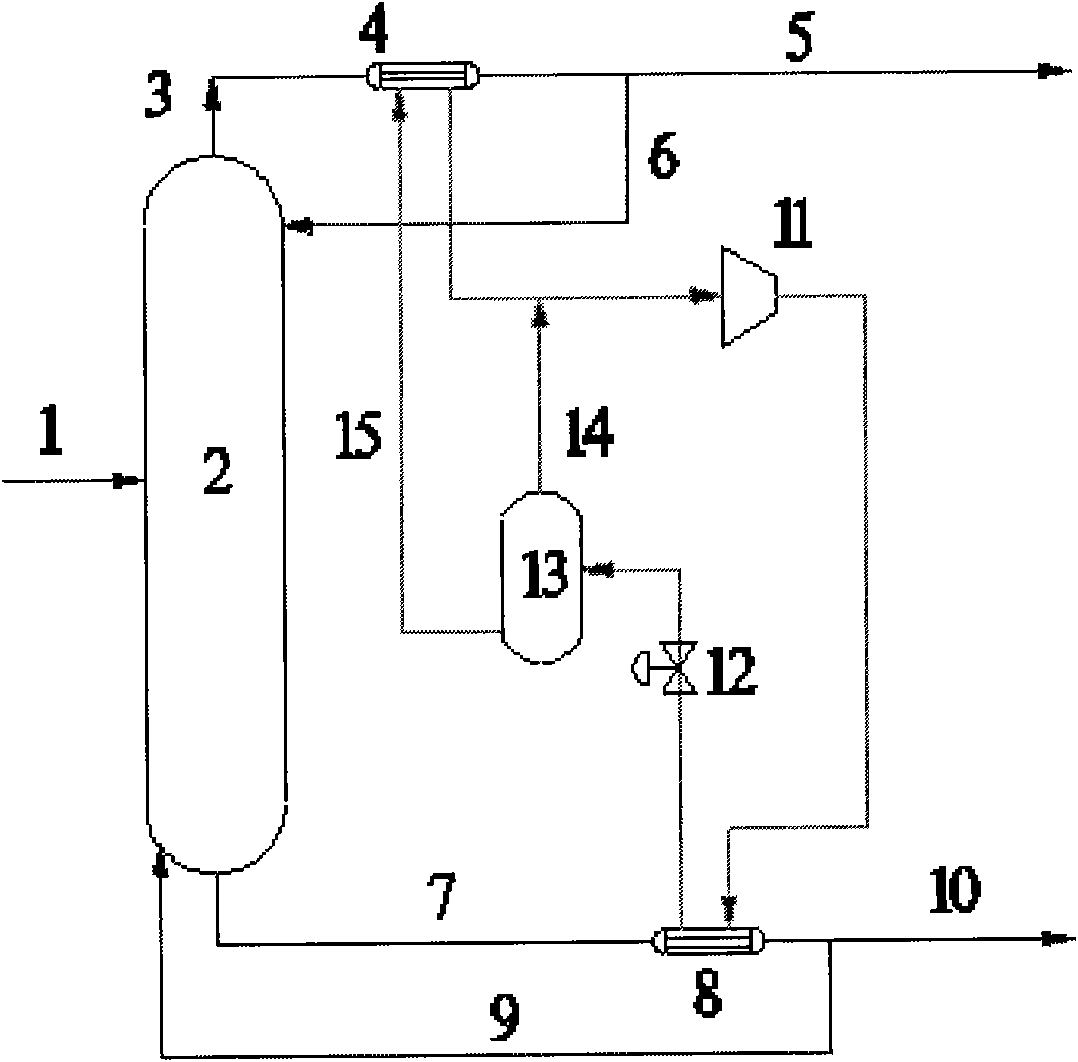

[0026] Adopt flow process shown in Fig. 1, acetic acid aqueous solution 1 (wherein acetic acid concentration is 38 mass %) enters acetic acid dehydration tower 2 from the middle, after rectifying separation, tower top obtains gaseous phase stream 3, tower still obtains liquid phase stream 7; Stream 3 After heat exchange and condensation in the condenser 4, it is divided into a stream 5 and a stream 6. The stream 5 enters the follow-up process as a tower top product discharge, and the stream 6 returns to the top of the acetic acid dehydration tower 2; It is logistics 9 and logistics 10, logistics 9 returns to the bottom of 2, and logistics 10 enters the subsequent process as the output of the tower kettle product. The concentration of acetic acid in the discharge from the bottom of the acetic acid dehydration tower is greater than 94% by mass, and the concentration of acetic acid in the discharge from the top of the tower is less than 0.1% by mass.

[0027] The heat exchange me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com