Mold stripping structure with buckles at two different angles

An angle and buckle technology, which is applied in the field of mold release structure, can solve the problems of increasing equipment loss, reducing production efficiency, and affecting the effect of mold release, so as to avoid equipment loss and ensure production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

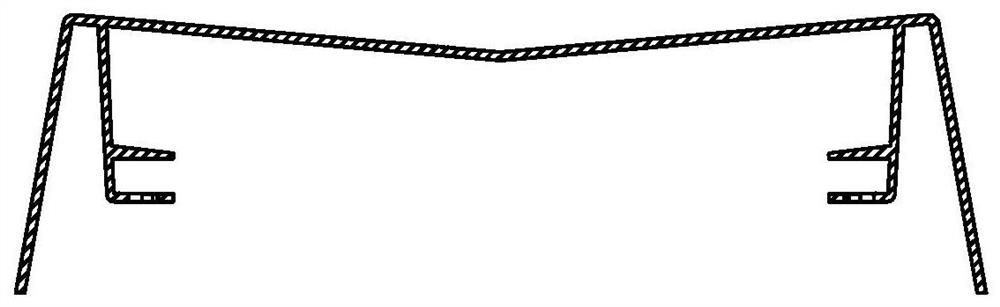

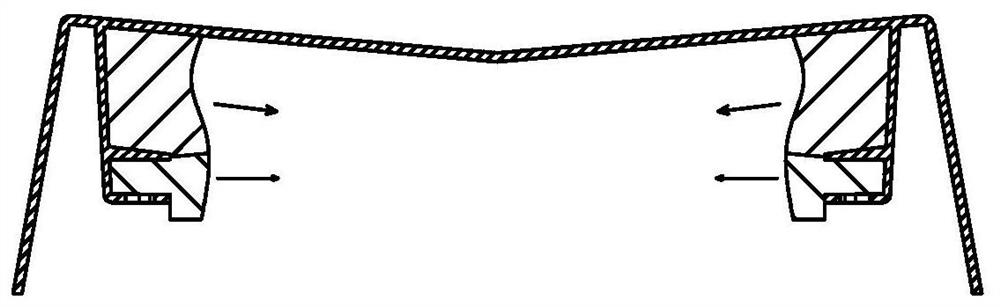

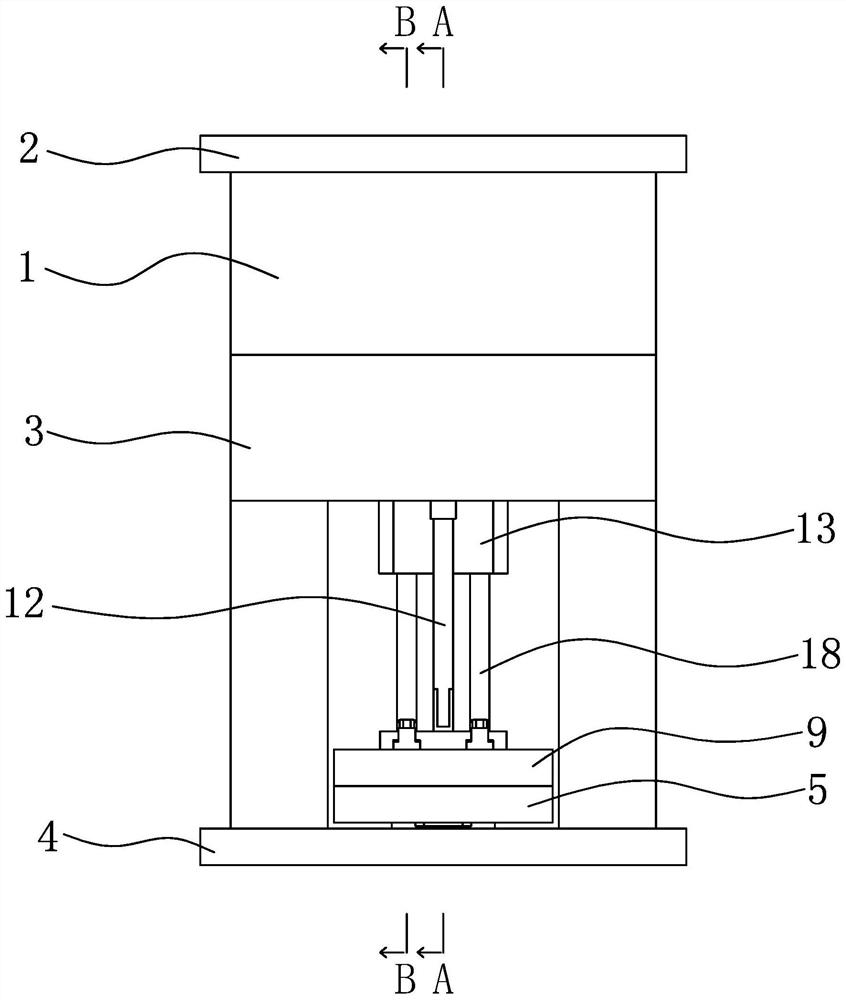

[0058] Specific embodiment one: as Figure 3 to Figure 7 As shown, a buckle has two different angles of ejection structure, including:

[0059] Upper mold 1, upper mold fixing plate 2, lower mold 3 and lower mold fixing plate 4;

[0060] Also includes:

[0061] The first ejector plate 5, the first ejector plate 5 is located above the lower mold fixing plate 4, the first ejector plate 5 is slid to be provided with a first slider 6; the first ejector plate 5 is provided with a jack block 7; the first ejector plate There is an ejector hole 8 on the top 5, and the ejector hole 8 runs through the first ejector plate 5 and the lower die fixing plate 4;

[0062] The second ejector plate 9, the second ejector plate 9 is located above the first ejector plate 5, and the second ejector plate 9 is provided with a second slide block 10; When the pull hook 11 hooks the top block 7;

[0063] The ejector pin 12, the ejector pin 12 is arranged at the lower part of the lower mold 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com