Efficient internal and external work exchanging table of thermal spraying

A technology for exchanging tables and thermal energy, which is applied in the direction of spraying booths, spraying devices, etc., can solve the problems of losing advantages and reducing the application value of thermal spraying processing technology, achieve good sound insulation effect, improve thermal spraying production efficiency, avoid ineffective energy consumption and The effect of equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

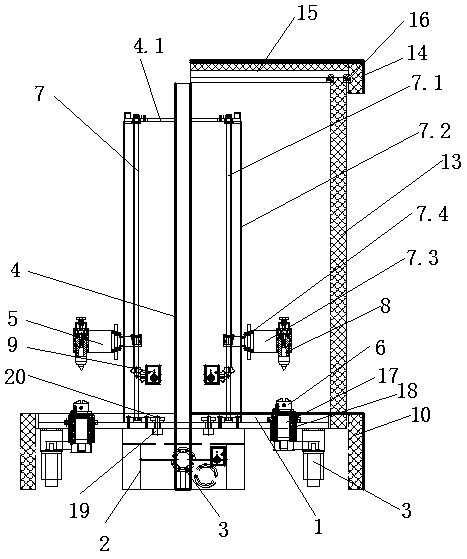

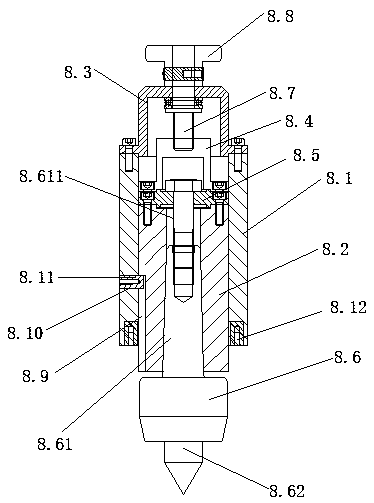

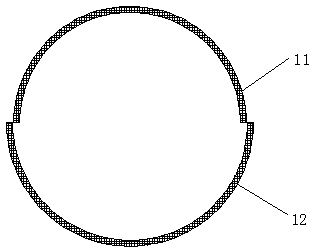

[0022] Embodiment 1: A high-efficiency thermal energy spraying internal and external work exchange table, including a circular turntable 1, the bottom of the circular turntable 1 is provided with a bottom support 2, and the bottom support 2 is provided with a motor 3 that drives the rotation of the circular turntable 1, The top of the circular turntable 1 is provided with a vertically arranged soundproof wall 4 that divides the upper part of the circular turntable 1 into two areas, the bottom support 2 is provided with two cylinders 19, and the circular turntable 1 is provided with a hole for inserting the piston rod of the cylinder 19. Inserting sleeve 20, inserting sleeve 20 is respectively located in two regions. Both areas are provided with a clamp assembly 5, the clamp assembly 5 includes a lower clamp 6 located on the circular turntable 1, a vertically arranged guide mechanism 7, an upper clamp 8 located on the guide mechanism 7, and pushes the upper clamp 8 to move up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com