Supercritical heat accumulating type organic Rankine cycle exhaust afterheat comprehensive utilization device

A Rankine cycle, supercritical technology, applied in exhaust devices, steam engine devices, mufflers, etc., can solve the problems of inefficient utilization of mechanical energy of waste heat, low utilization rate of waste heat from exhaust gas, narrow window for suitable temperature, etc. Work conversion efficiency, improved implementation, effect of low-quality energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

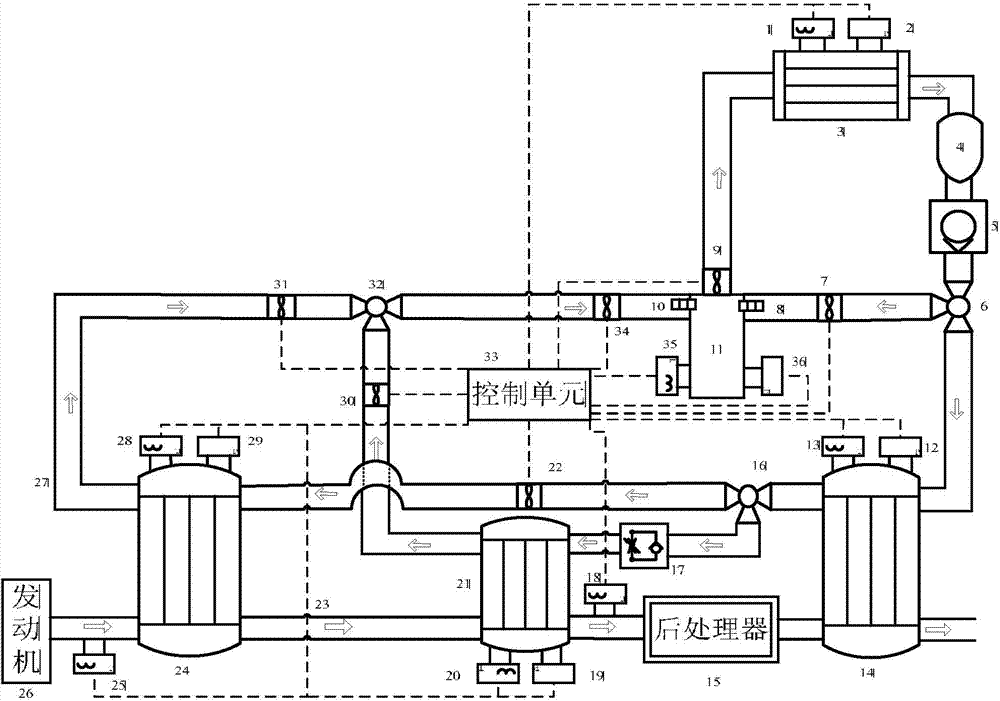

[0023] The following is attached figure 1 Further elaborate on the technical solution of the present invention: the present invention consists of a temperature sensor I1, a pressure sensor I2, a condenser 3, a working medium storage tank 4, a working medium pump 5, a tee joint I6, a working medium injection solenoid valve I7, and a working medium nozzle Ⅰ8, solenoid valve Ⅰ9, working medium nozzle Ⅱ10, expander 11, pressure sensor Ⅱ12, temperature sensor Ⅱ13, preheater 14, postprocessor 15, tee joint Ⅱ16, flow control valve 17, temperature sensor Ⅲ18, pressure sensor Ⅲ19 , temperature sensor Ⅳ20, supercritical heat accumulator 21, solenoid valve Ⅱ22, exhaust pipe 23, superheated evaporator 24, temperature sensor Ⅴ25, engine 26, working medium circulation pipe 27, temperature sensor Ⅵ28, pressure sensor Ⅳ29, solenoid valve Ⅲ30 , Solenoid valve Ⅳ31, tee joint Ⅲ32, control unit 33, working medium injection solenoid valve Ⅱ34, temperature sensor Ⅶ35 and pressure sensor Ⅴ36.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com