Method for separating acetic acid from water by acetic acid dehydration tower

A technology of acetic acid dehydration and acetic acid aqueous solution, which is applied in the separation/purification of carboxylic acid compounds, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of high energy consumption, high operating cost and high equipment manufacturing cost for acetic acid dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

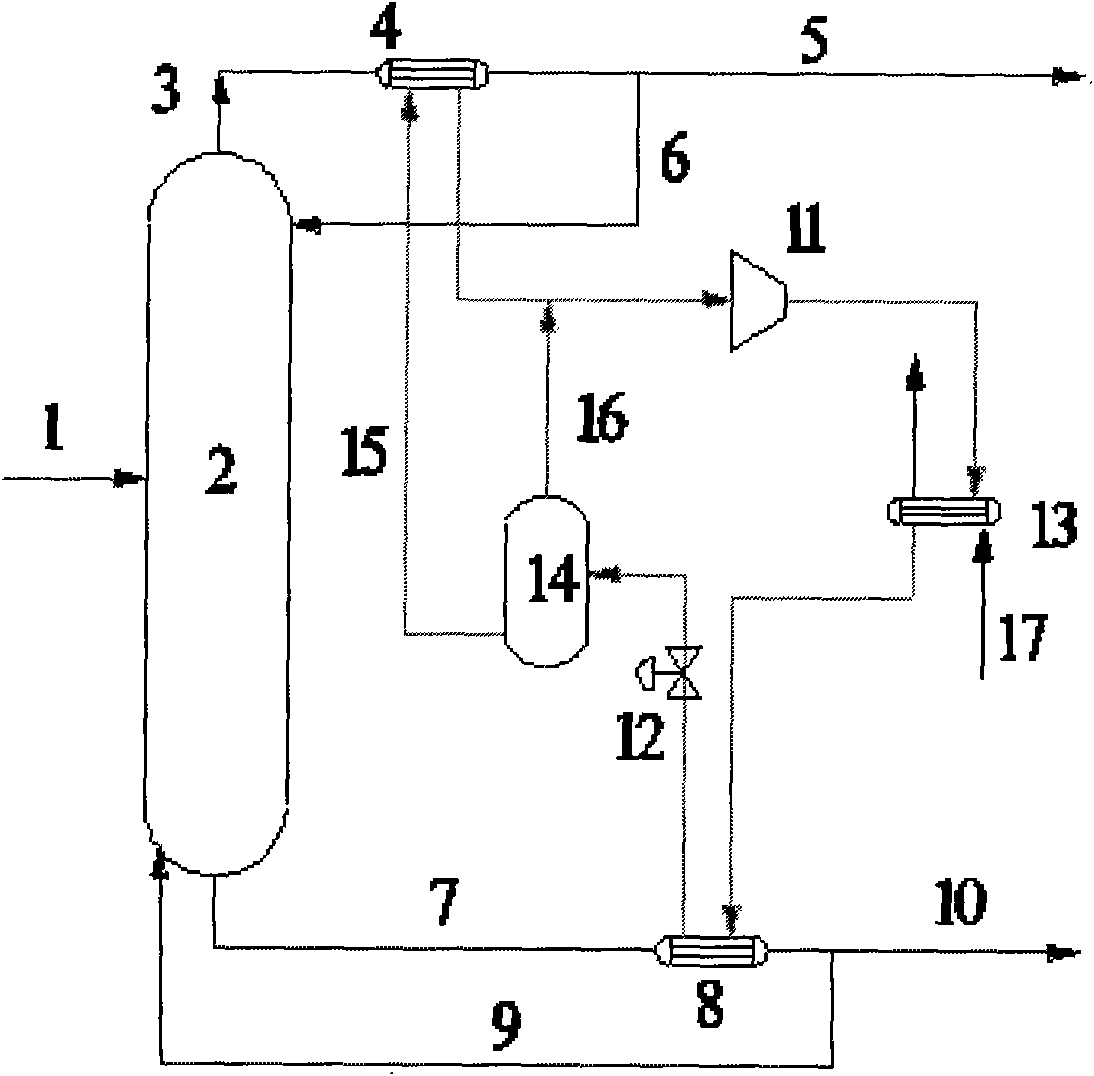

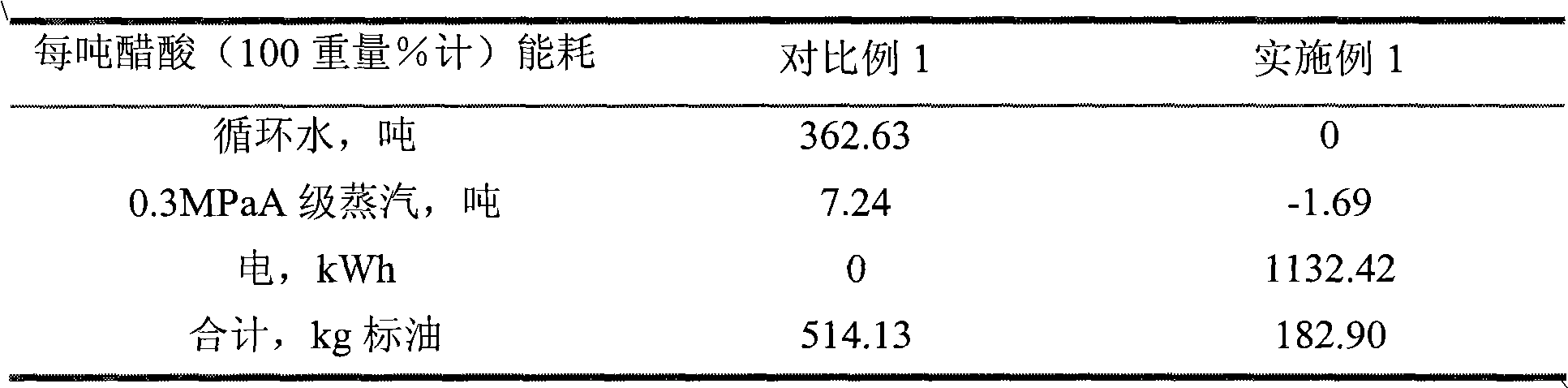

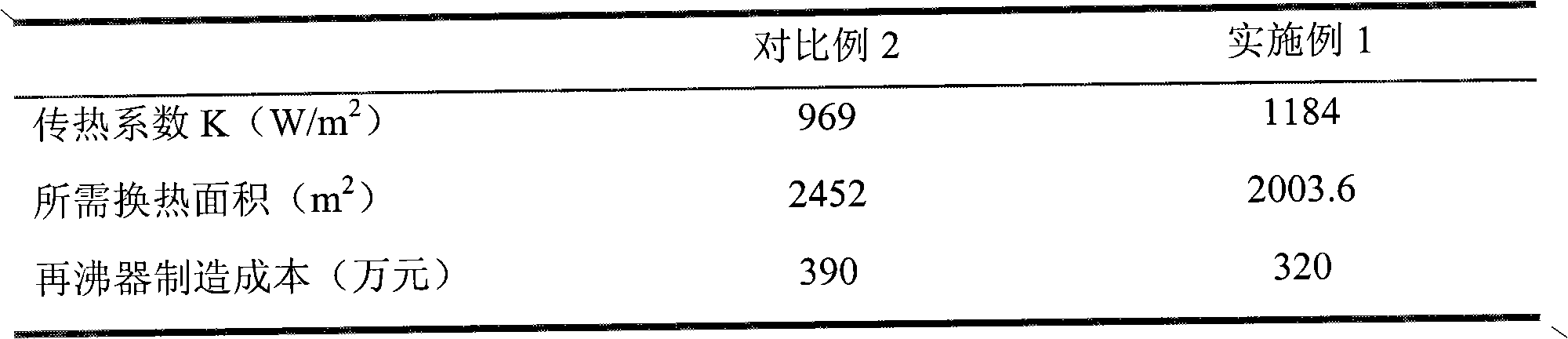

[0026] use figure 1 As shown in the flow process, the acetic acid aqueous solution 1 (wherein the acetic acid concentration is 38% by mass) enters the acetic acid dehydration tower 2 from the middle, and after being separated by rectification, the gaseous phase stream 3 is obtained at the top of the tower, and the liquid phase stream 7 is obtained at the bottom of the tower; the stream 3 passes through the condenser 4 After heat exchange and condensation, it is divided into logistics 5 and logistics 6. Logistics 5 enters the follow-up process as the tower top product discharge, and logistics 6 returns to the top of acetic acid dehydration tower 2; after the heat exchange of reboiler 8, logistics 7 is divided into logistics 9 And logistics 10, logistics 9 returns to the bottom of 2, and logistics 10 enters the follow-up process as the output of the tower kettle product. The concentration of acetic acid in the discharge from the bottom of the acetic acid dehydration tower is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com