Comprehensive sludge treating method based on hydrothermal carbonization and fast microwave pyrolysis

A hydrothermal carbonization and comprehensive treatment technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of high water content in sludge and achieve a high degree of resource utilization , Overcoming the effect of low calorific value and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

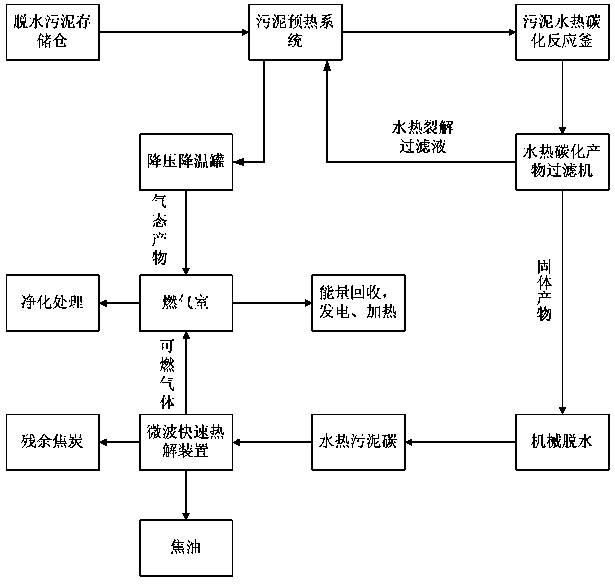

Method used

Image

Examples

Embodiment 1

[0034] (1) Send dewatered sludge with a mass of 100g and a moisture content of about 76.2wt% to the sludge preheating system to preheat to 90°C;

[0035] (2) The preheated sludge is pumped into the sludge hydrothermal carbonization reactor for hydrothermal carbonization reaction. The hydrothermal reaction temperature is 180 °C, the autogenous pressure is 2.2 MPa, the reaction time is 0.5 h, the rotation speed is 120 rpm, and the Into nitrogen to ensure that the reaction is carried out in an inert atmosphere;

[0036] (3) The obtained hydrothermal carbonization product is subjected to solid-liquid separation with a filter. The hydrothermal cracking filtrate (170 ℃) enters the pipeline of the sludge preheating system to preheat the dewatered sludge; the separated solids are mechanically dehydrated to obtain 36.9g of hydrothermal sludge carbon with a moisture content of 37.6 wt%;

[0037] (4) After the hydrothermal cracking filtrate preheats the dewatered sludge, it enters the d...

Embodiment 2

[0040] (1) Send dewatered sludge with a mass of 100g and a moisture content of about 76.2wt% to the sludge preheating system to preheat to 110 °C;

[0041] (2) The preheated sludge is pumped into the sludge hydrothermal carbonization reactor for hydrothermal carbonization reaction. The hydrothermal reaction temperature is 220 °C, the autogenous pressure is 4.5 MPa, the reaction time is 1.0 h, the rotation speed is 150 rpm, and the Into nitrogen to ensure that the reaction is carried out in an inert atmosphere;

[0042] (3) The obtained hydrothermal carbonization product is subjected to solid-liquid separation with a filter. The hydrothermal cracking filtrate (200 ℃) enters the pipeline of the sludge preheating system to preheat the dewatered sludge; the separated solids are mechanically dehydrated to obtain 33.2g of hydrothermal sludge carbon with a moisture content of 31.2wt%;

[0043] (4) After the hydrothermal cracking filtrate preheats the dewatered sludge, it enters the ...

Embodiment 3

[0046] (1) Send dewatered sludge with a mass of 100g and a moisture content of about 76.2wt% to the sludge preheating system to preheat to 125 °C;

[0047] (2) The preheated sludge is pumped into the sludge hydrothermal carbonization reactor for hydrothermal carbonization reaction. The hydrothermal reaction temperature is 250 °C, the autogenous pressure is 7.5 MPa, the reaction time is 1.5 h, the rotation speed is 200 rpm, and the Into nitrogen to ensure that the reaction is carried out in an inert atmosphere;

[0048] (3) The obtained hydrothermal carbonization product is subjected to solid-liquid separation with a filter. The hydrothermal cracking filtrate (230 ℃) enters the sludge preheating system pipeline to preheat the dewatered sludge; the separated solids are mechanically dehydrated to obtain 31.3g of hydrothermal sludge carbon, with a moisture content of 27.5wt%,;

[0049] (4) After the hydrothermal cracking filtrate preheats the dewatered sludge, it enters the depre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com