Direct carbon electrochemical cell

一种电化学、电池的技术,应用在电化学电池领域,能够解决阳极反应复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

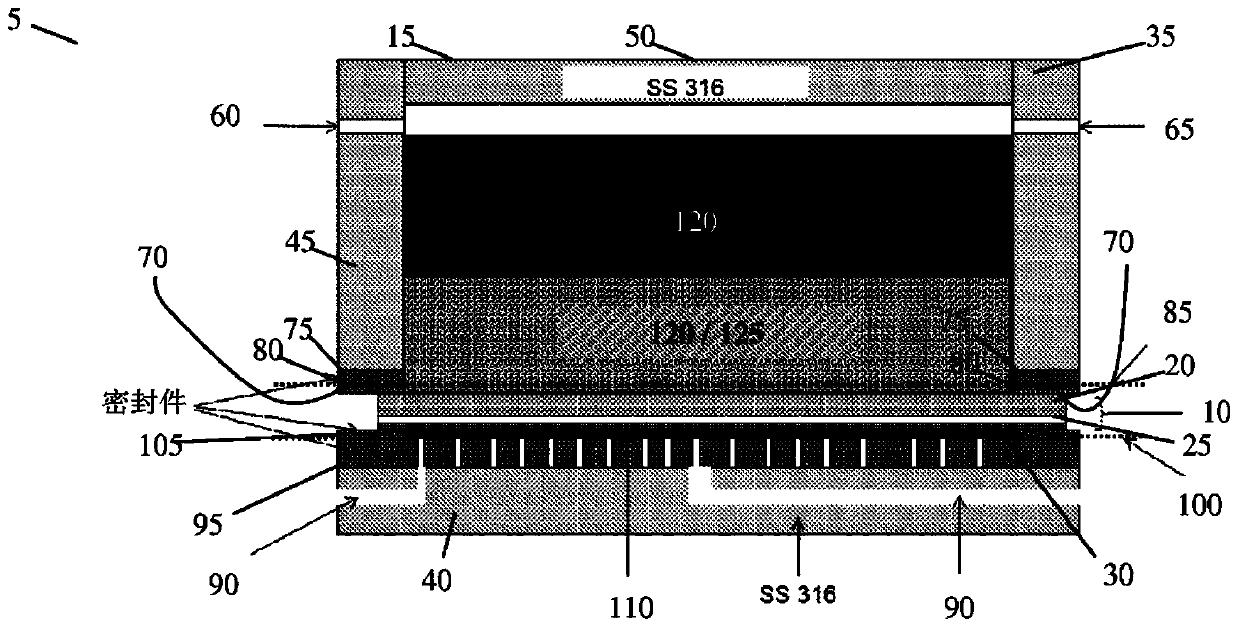

[0097] figure 1 Shown is a cross section of the direct carbon fuel cell system 5 . The system 5 includes a solid oxide electrochemical cell 10 provided within a cell housing 15 . The electrochemical cell 10 includes a solid oxide anode 20 , an ion-conducting solid oxide electrolyte 25 and a solid oxide cathode 30 .

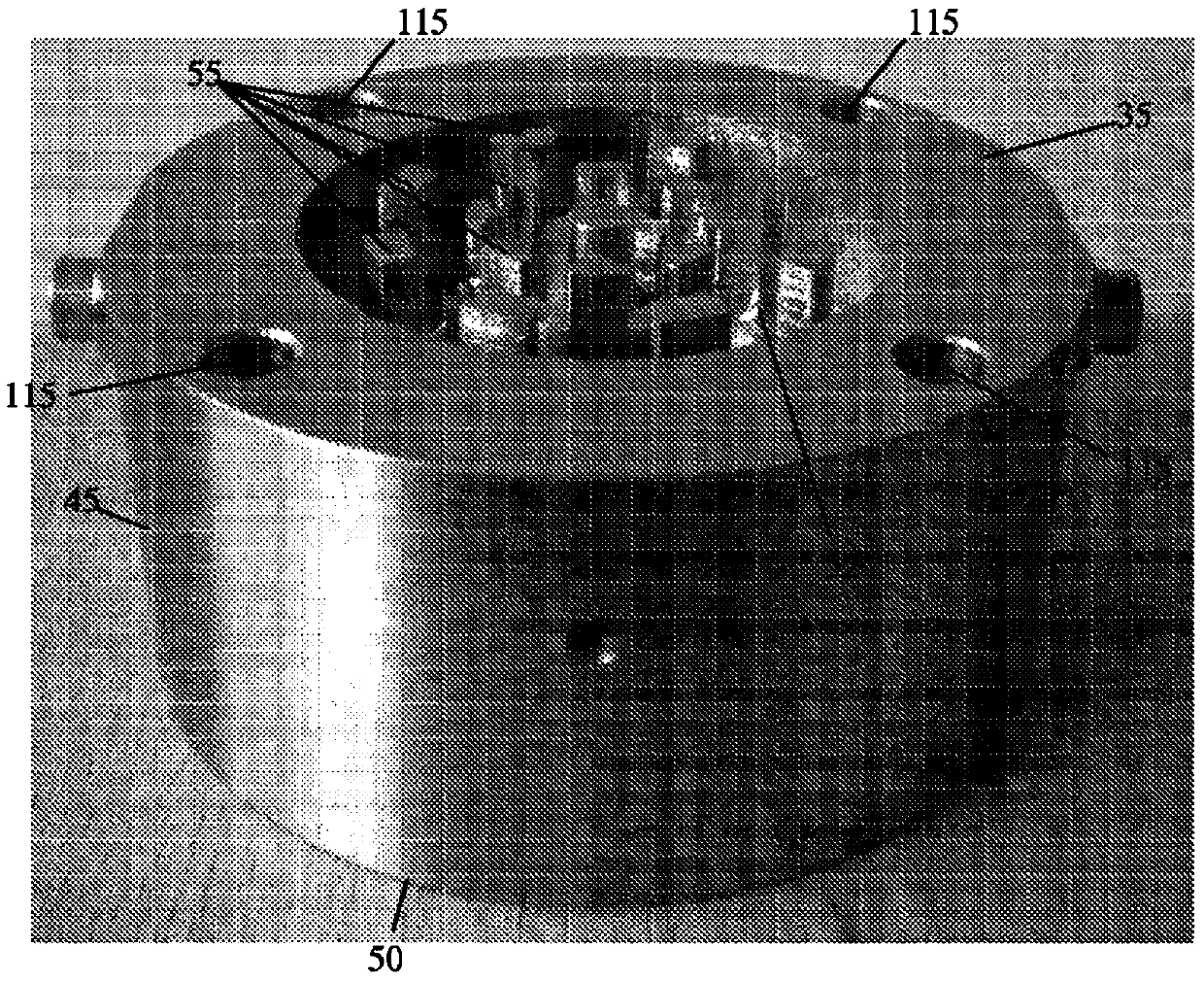

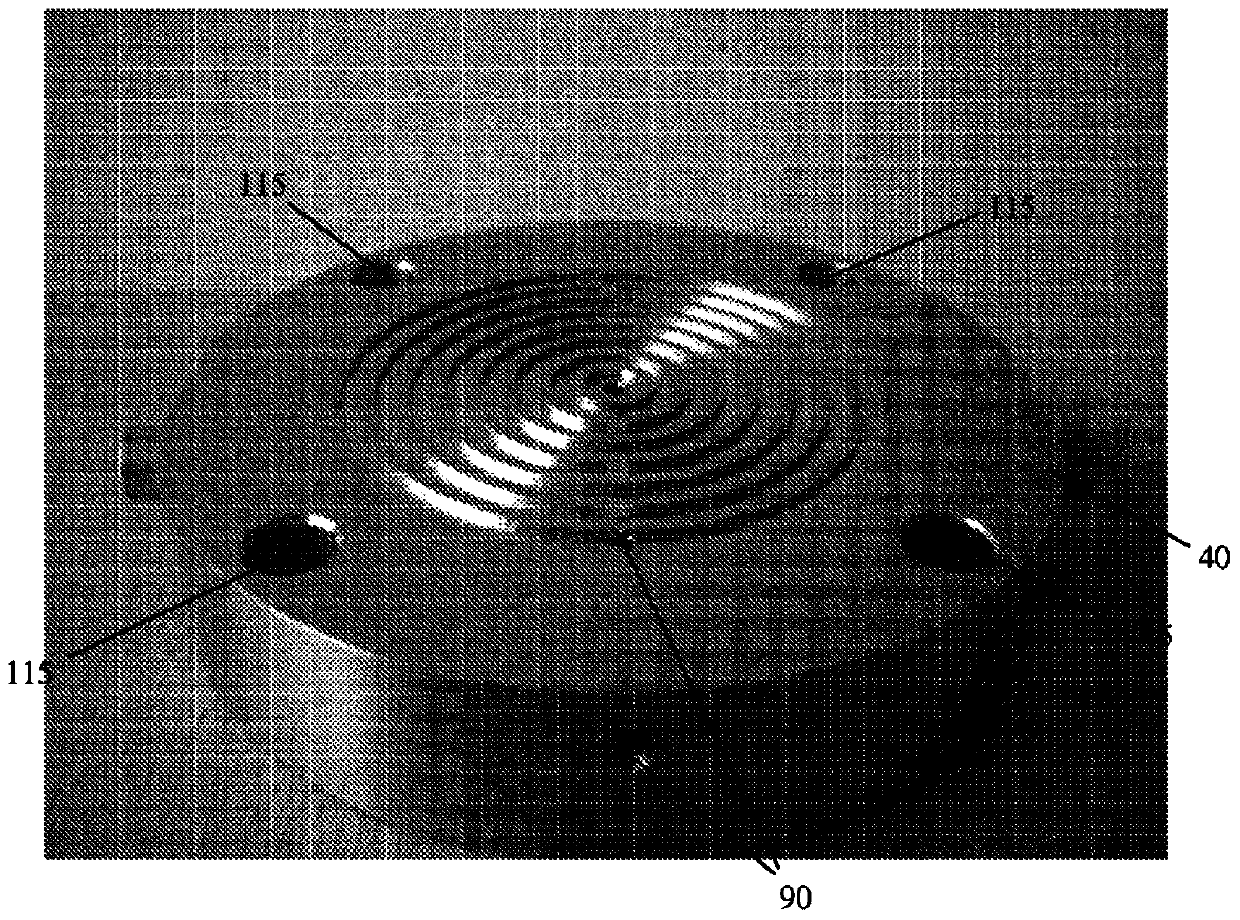

[0098] The housing 15 includes two distinct parts 35, 40, such as figure 2 and 3 As shown, anode casing 35 and cathode casing 40 are compressed and sealed together to sandwich cell 10 with anode 20 of cell 10 facing anode casing 35 and cathode 30 of cell 10 facing cathode casing 40 . In use, the cell 10 is arranged such that the anode casing 35 forms the upper end or top of the system 5 and the cathode casing 40 forms the lower end or bottom of the system 5 . The anode casing 35 is larger than the cathode casing and is configured to carry a mixture of fuel, catalyst and a second electrolyte (molten at operating temperature).

[0099] Anode side current colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com