A cathode material for direct carbon fuel cell and its manufacture method

A fuel cell cathode and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems that the interior of the battery and structural parts are corroded by electrolytes, hinder the practical application of DCFC, and have high requirements for electrode materials, and achieve low manufacturing costs. , The effect of promoting industrialization and high output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

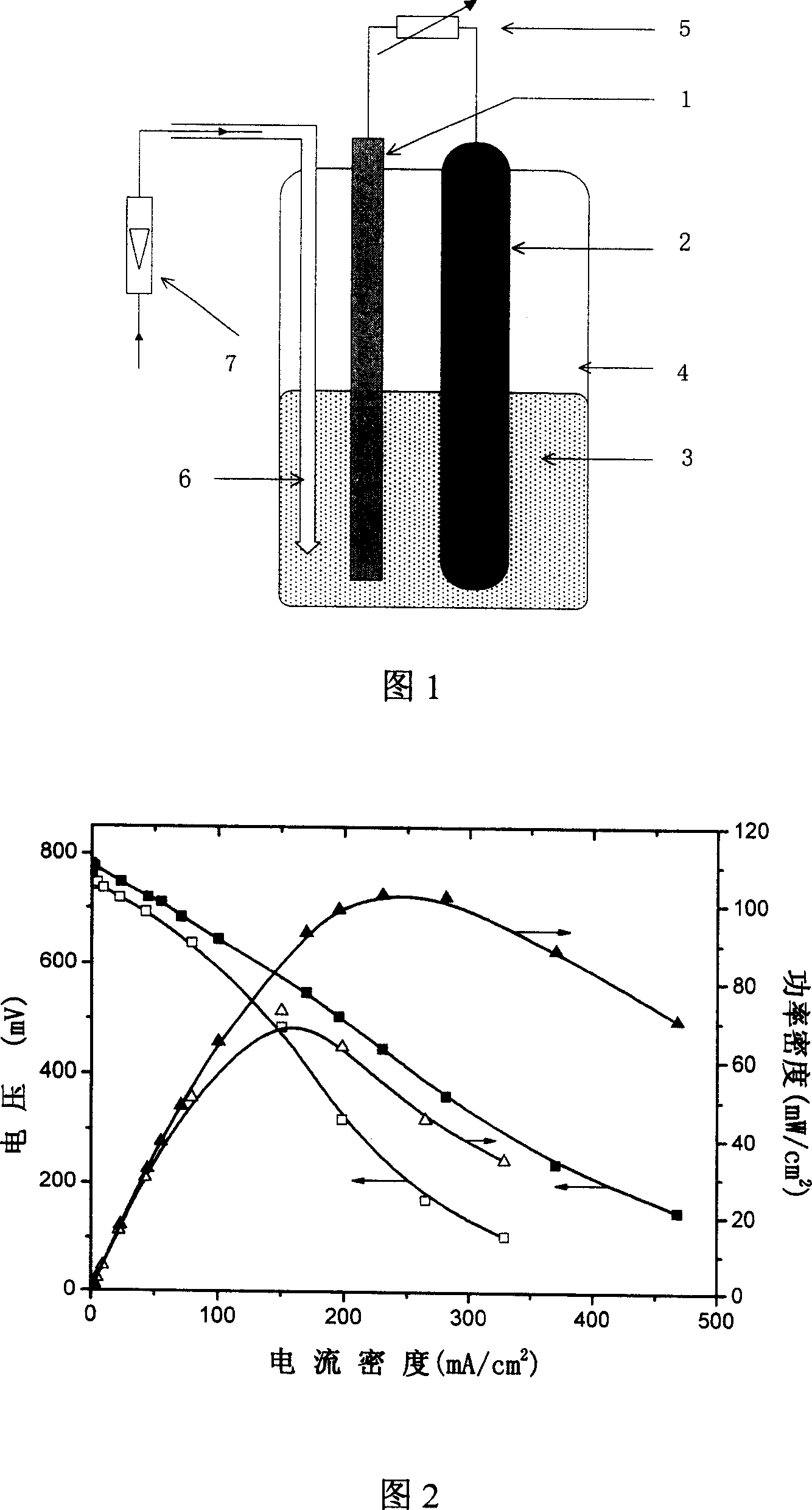

[0033] Embodiment 11 constructs DCFC unit cell

[0034] Weigh analytically pure NaOH, LiOH, KOH, Al(OH)3 , Y 2 o 3 , mixed according to the mole percentage of the electrolyte, NaOH 20-30%, LiOH 10-20%, KOH 40-50%, Al(OH) 3 10-30%, Y 2 o 3 1-15%, after fully mixing, take out and dry as electrolyte. The distance between the anode and the cathode is 0.5-5cm, and the air flow rate of the cathode is 10-100ml / min. The anode material is graphite, and the cathode is the materials of Examples 1-10 respectively. The working temperature is 500℃~630℃. The structure of a direct carbon fuel cell unit cell is shown in Figure 1.

Embodiment 12

[0035] Embodiment 12 power density test

[0036] The rare earth oxide composite cathode material of Example 3 was placed in a DCFC unit cell to test the DCFC volt-ampere characteristic curve. The variation curves of DCFC power density and open circuit voltage with current density were measured at 500°C and 630°C, respectively. Electrode effective area 3.23cm 2 . The volt-ampere characteristics of the battery are shown in Figure 2. It can be seen that the maximum power density of DCFC at 500°C is 70mW / cm 2 , the maximum current density is 328mA / cm 2 ;The maximum power density of DCFC at 630℃ is 102mW / cm 2 , the maximum current density is 467mA / cm 2 . Table 2 shows the experimental parameters and battery performance data of DCFC at 500°C and 630°C.

[0037] Table 2. 500°C and 630°C DCFC parameters and performance

[0038] Operating temperature

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Maximum current density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com