Nickel-lanthanum composite material cathode and direct carbon fuel cell and preparation method thereof

A composite material and fuel cell technology, which is applied in fuel cells, molten electrolyte fuel cells, battery electrodes, etc., can solve the problems of negative ion conductivity, low current density and power density, and high production cost that affect the catalytic activity of cathode oxygen dissociation reduction , to achieve the effect of low cost, high power density and current density, and easy control of composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

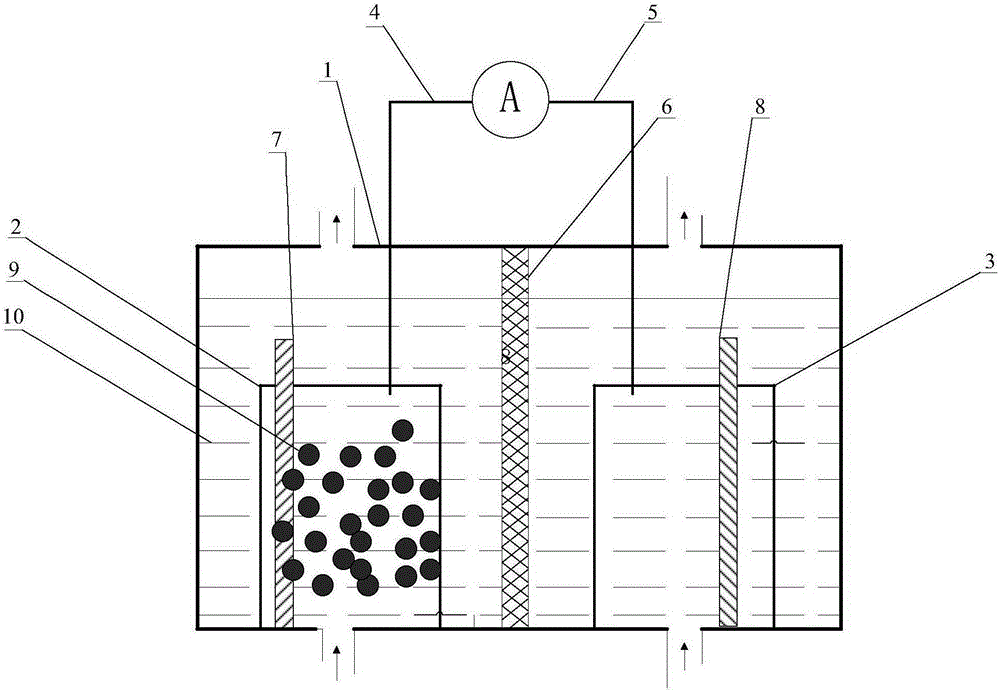

[0040] Such as figure 1 As shown, the direct carbon fuel cell of this embodiment includes: a reaction device 1, an anode compartment 2, a cathode compartment 3, an anode 7, a cathode 8, an anode current collector 4, a cathode current collector 5, and a microporous separator 6 , molten alkali electrolyte 10 and carbon fuel 9; wherein, in reaction device 1, be full of molten alkali electrolyte 10; Cylindrical anode plate bin 2 and cathode plate bin 3 are respectively arranged at the bottom of reaction device 1; Anode 7 and cathode 8 are respectively Placed in the anode plate bin 2 and the cathode plate bin 3; the anode current collector plate 4 and the cathode current collector plate 5 with holes penetrate and extend into the anode plate bin and the cathode plate bin from the top of the reaction device respectively; A microporous separator ...

PUM

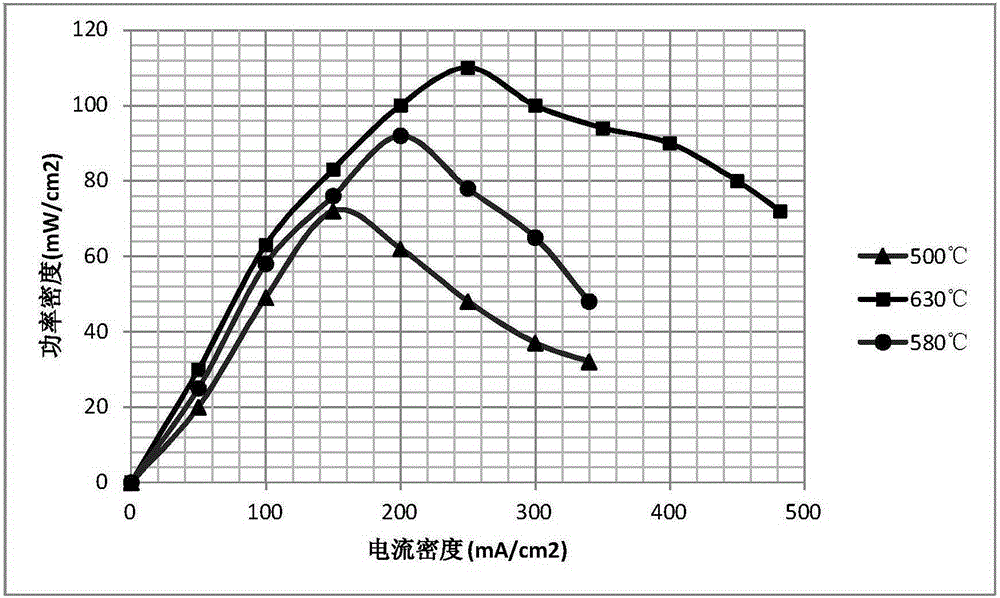

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com