Direct carbon fuel cell using eutectic fusible hydroxide mixture as electrolyte

A fuel cell and hydroxide technology, used in molten electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of strong corrosiveness and high reaction temperature of molten hydroxide, avoid consumption and improve electrochemical reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

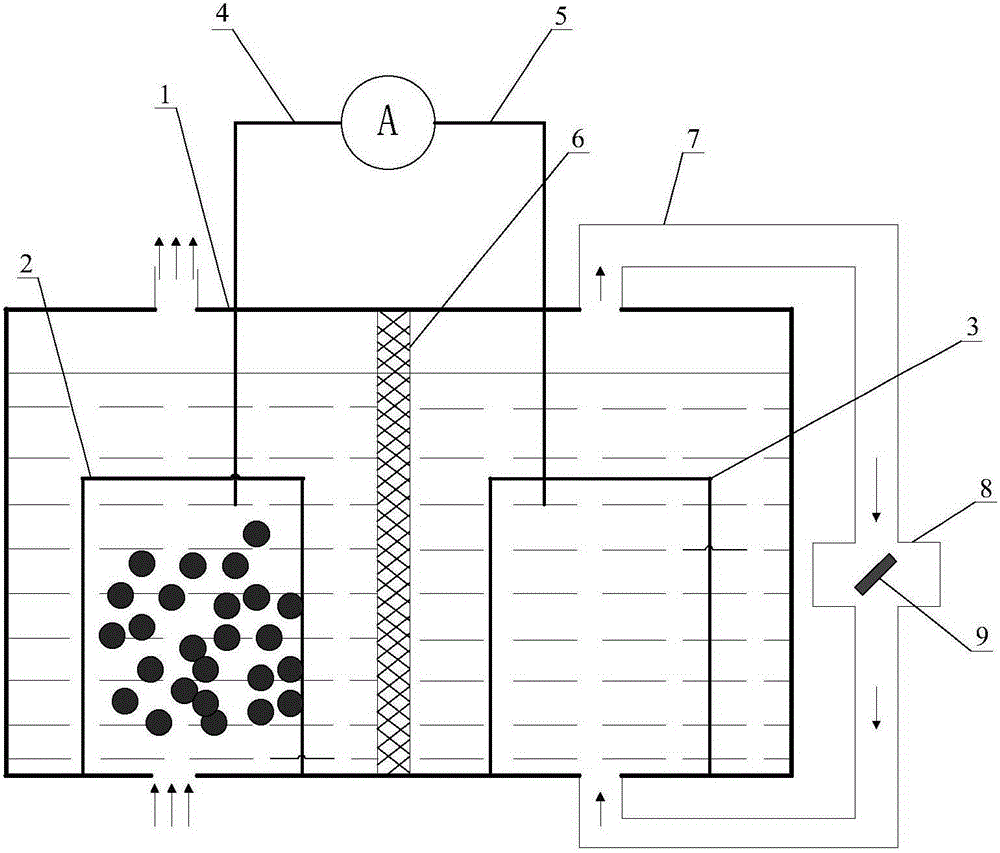

[0029] Such as figure 1 As shown, the direct carbon fuel cell of this embodiment includes: reaction device 1, anode plate bin 2, cathode plate bin 3, anode current collector plate 4, cathode current collector plate 5, microporous separator 6, cathode pipeline 7, air Circulation device 8, throttle plate 9, electrolyte and carbon fuel; wherein, the reaction device 1 is filled with electrolyte; the cylindrical anode plate warehouse 2 and the cathode plate warehouse 3 are respectively arranged at the bottom of the reaction device 1; the anode current collector with holes Plate 4 and cathode current collecting plate 5 penetrate respectively from the top of the reaction device and extend into the anode plate warehouse and the cathode plate warehouse; a microporous separator 6 is set between the anode plate warehouse and the cathode plate warehou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com