Preparation method of carbon nanotube reinforced polyimide nano composite material

A nanocomposite material and carbon nanotube technology, applied in the direction of single-component synthetic polymer rayon, fiber chemical characteristics, textiles and papermaking, can solve the problem of reducing the length and structure of carbon nanotube fibers, structural damage, and mechanical performance enhancement and other problems, to achieve the effect of improving comprehensive mechanical properties, improving thermal stability, and improving toughness

Active Publication Date: 2011-06-15

TSINGHUA UNIV

View PDF4 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

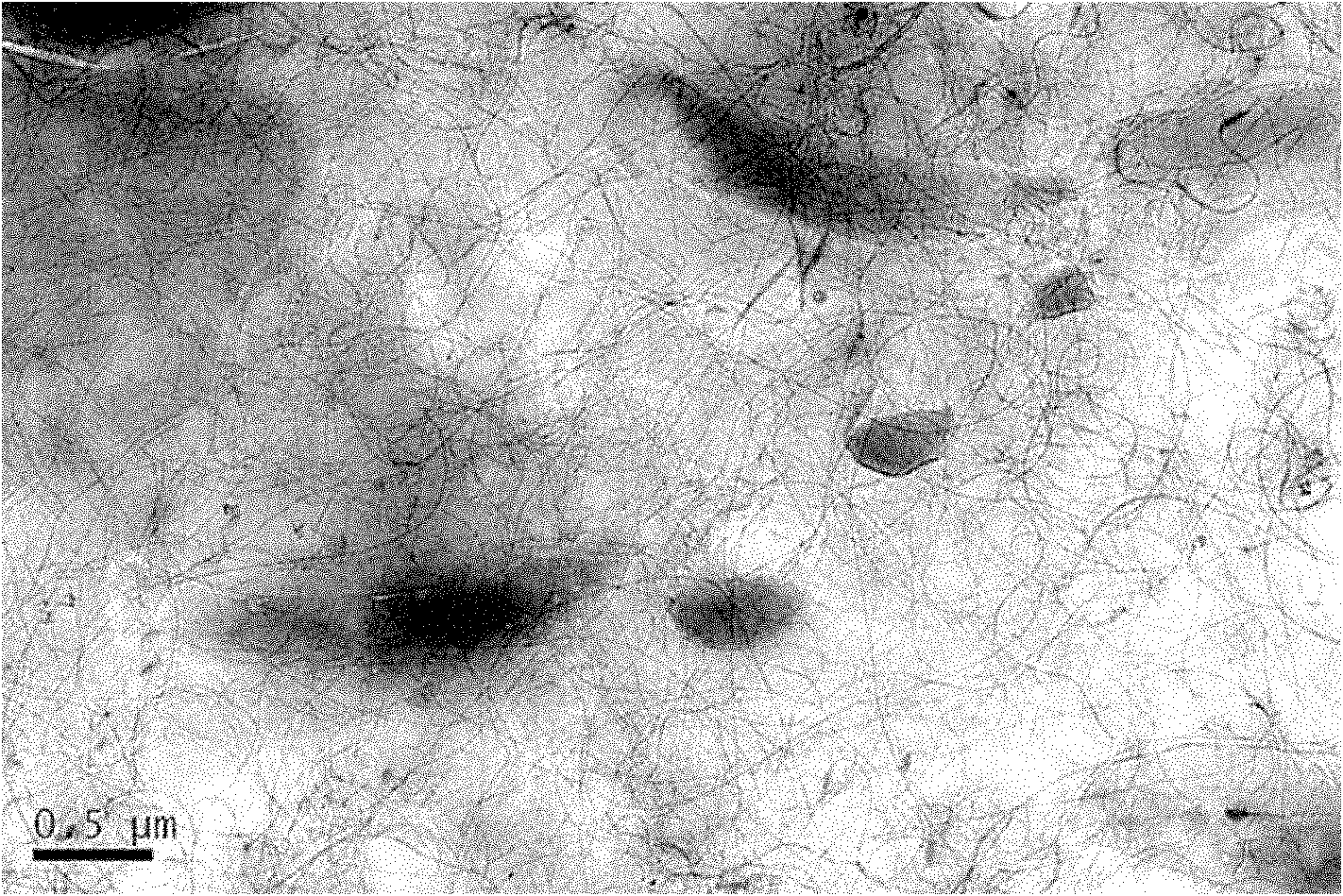

However, we can see that in the carbon nanotube-reinforced polymer composites reported in the above literature and most other literatures, the carbon nanotubes have relatively different structures due to their own defects, or in the process of mixed acid oxidation treatment or functional modification. The large degree of destruction greatly reduces the length and structure of carbon nanotube fibers, which makes the length of carbon nanotubes in the matrix mostly less than 5 microns, so the enhancement of mechanical properties is limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

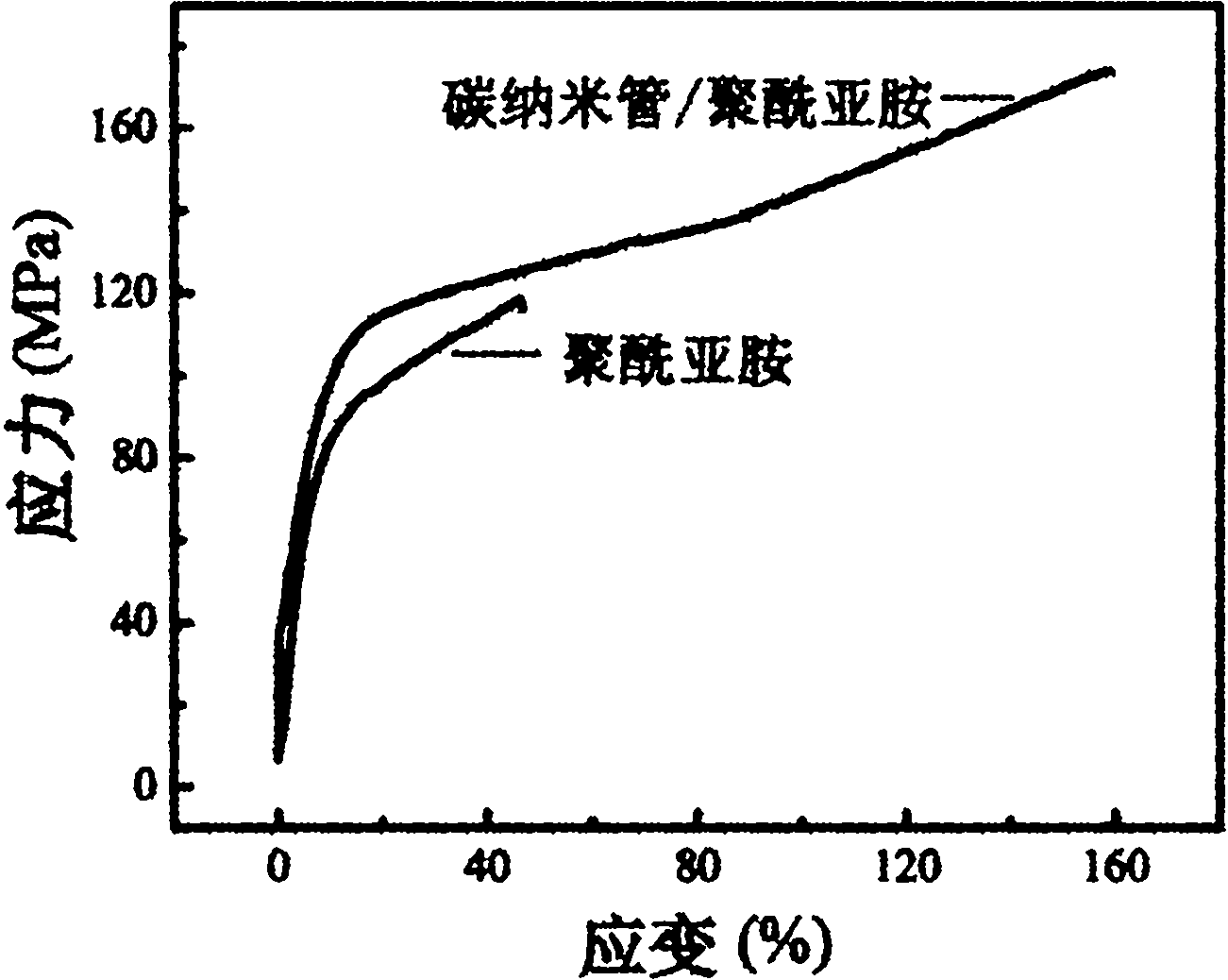

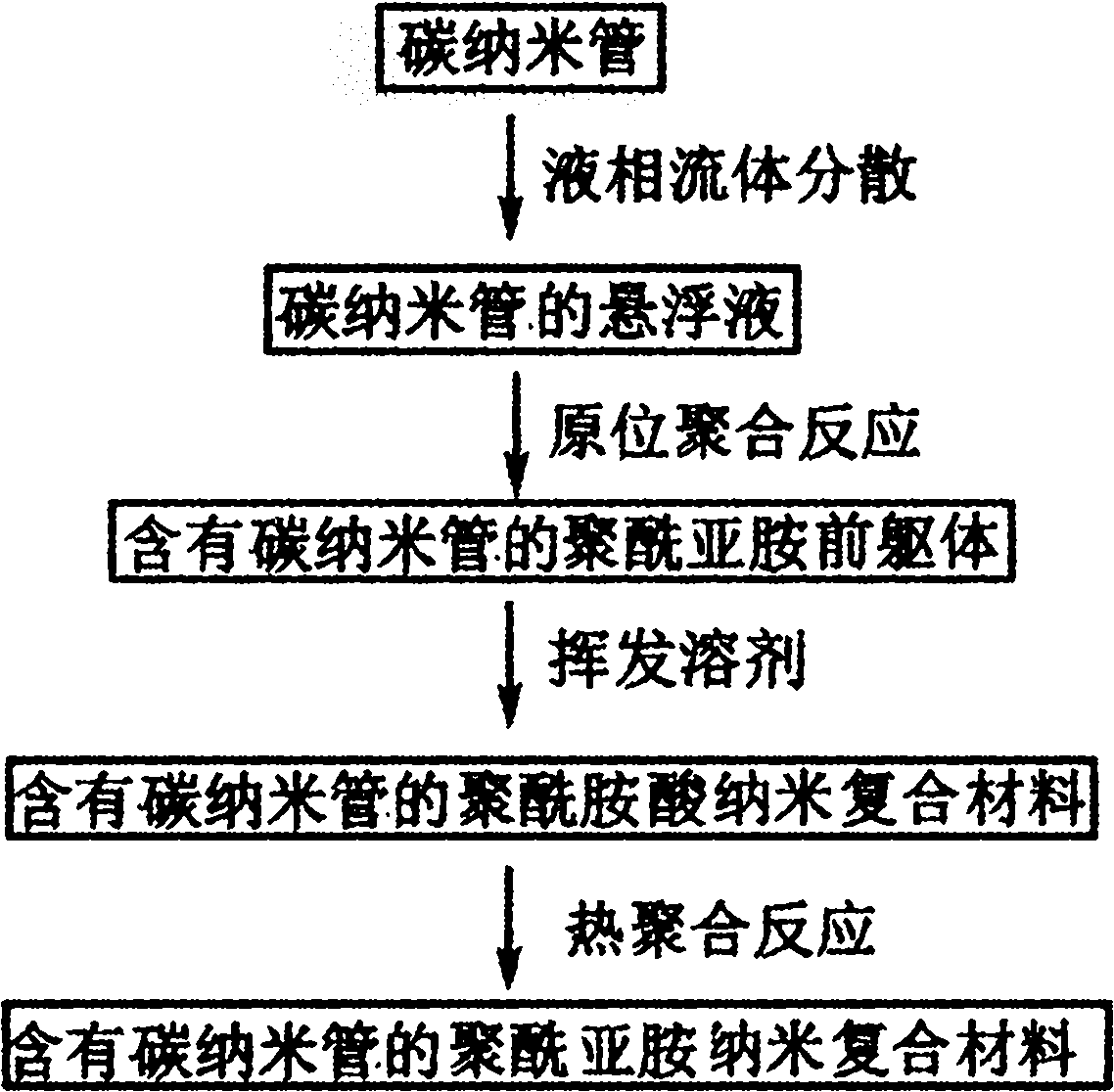

The invention relates to a preparation method of a carbon nanotube reinforced polyimide nano composite material, which comprises the following steps: carrying out liquid-phase shearing dispersion on 10-10000 micrometer long carbon nanotubes in an organic solvent; adding 4,4-diaminodiphenyl ether and pyromellitic dianhydride into the dispersed carbon nanotube slurry to carry out an in-situ polymerization reaction; and carrying out vacuum degasification to obtain a thin film or fibers, volatilizing the solvent, and carrying out heat treatment to obtain the carbon nanotube / polyimide nano composite material. By using the high-length-diameter ratio carbon nanotubes to provide interfaces for adequate slip of polyimide molecules and favorable interface combination, the composite material has excellent mechanical properties, thereby being hopefully applied to fields such as aerospace, automobiles, flexible substrates and the like.

Description

A kind of preparation method of carbon nanotube reinforced polyimide nanocomposite material technical field The invention relates to a preparation method for carbon nanotubes to enhance the performance of polymer materials, and belongs to the field of preparation of nanocomposite materials. Background technique Polyimide is an engineering plastic widely used in fields such as microelectronics and aerospace due to its good thermal stability, mechanical properties and flexibility. Due to differences in raw materials, the tensile strength of pure polyimide is mostly 80-110MPa, and the elongation at break is mostly 10-50%, so the toughness is limited. However, the rise of nanocomposites has made it possible to further improve the mechanical properties of polyimides. Among them, carbon nanotubes have excellent mechanical properties, such as high strength close to 100GPa, high modulus of 1TP, low density, and excellent electrical conductivity and heat transfer properties, so th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L79/08C08K7/00C08K3/04D01F6/94C08G73/10

Inventor 魏飞贾希来张强徐光辉赵梦强黄佳琦

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com