Electrostatic spinning preparation method of cellulose nanofibers having hollow porous structures

A porous structure, nanofiber technology, applied in the direction of man-made filaments in cellulose solution, chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of cumbersome, multi-time, cumbersome preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Prepare mixed cellulose solution.

[0057] Cotton fibers were first activated by soaking in water, methanol, and dimethylacetamide (DMAc) for 1 hour in sequence, and then dissolved in a DMAc / LiCl (92:8) solvent system. Then add a certain amount of iron salts, ferric chloride, ferric nitrate, ferric sulfate, ferric acetate, etc. into the solution, and stir until they are evenly mixed.

[0058] (2) Preparation of functional fibers by electrospinning.

[0059] Fill the mixed cellulose solution into the syringe, and then spin it at a propulsion speed of 0.03mL / min, set the positive and negative voltages to 20KV and -1KV, respectively, and the rotating metal roller as a collection device. The cellulose coagulation bath is an alkaline solution with a certain concentration. Hollow porous nano-hybrid fibers can be produced.

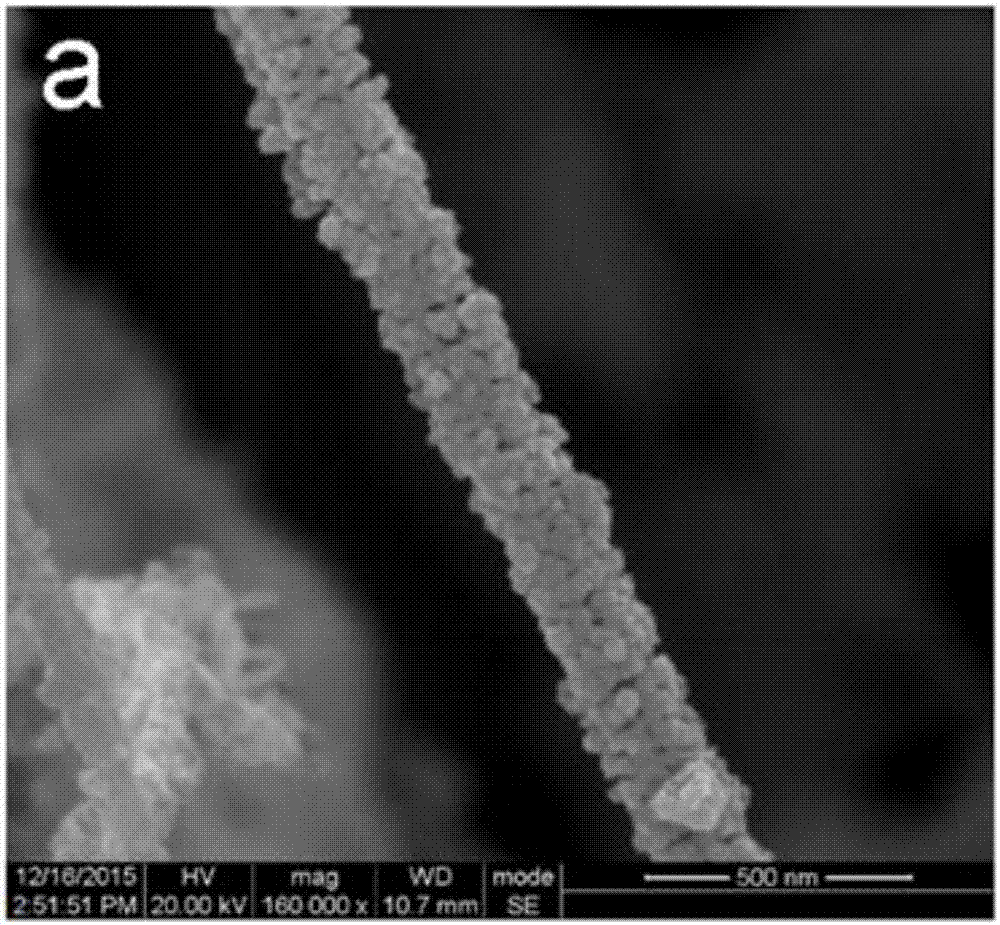

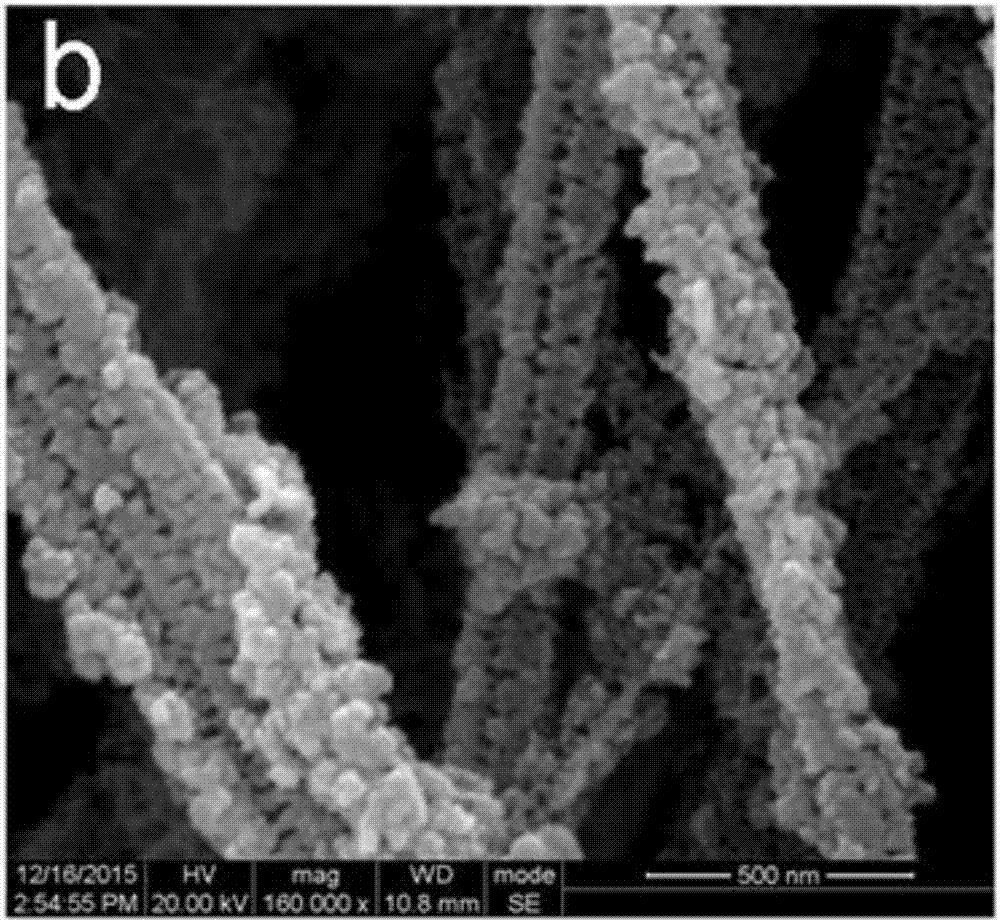

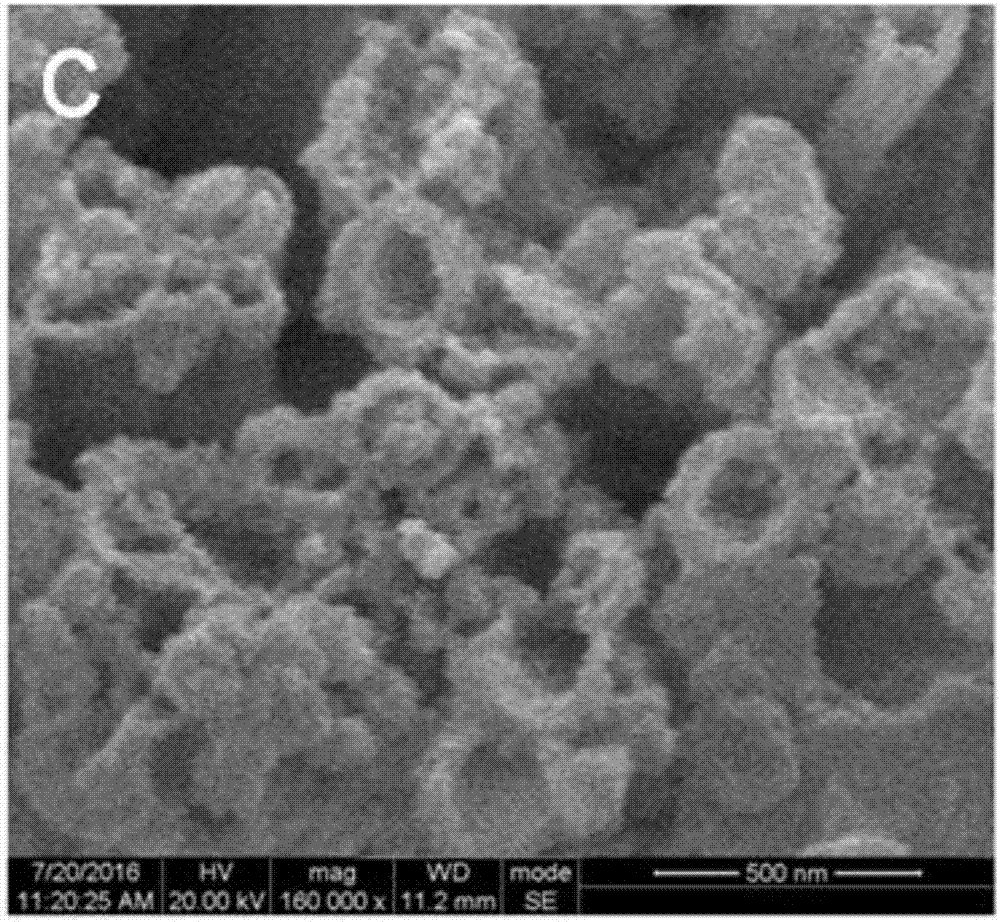

[0060] Figure 1 shows the one-step process of electrospinning to prepare hollow porous nanocellulose fibers loaded with Fe(OH) 3 The SEM picture. ...

Embodiment 2

[0062] Prepare the cellulose solution, then add a certain amount of aluminum salt into the solution, such as aluminum chloride, aluminum sulfate, aluminum nitrate, aluminum acetate, etc., stir until the mixture is uniform, then electrospin, and use the alkali solution as the coagulation bath, you can get Hollow nano-hybrid fibers. All the other processes are the same as in Example 1.

Embodiment 3

[0064] Prepare the cellulose solution, then add a certain amount of magnesium salt, magnesium chloride, magnesium sulfate, magnesium nitrate, magnesium acetate, etc. to the solution, stir until it is evenly mixed, and then electrospin, and use the alkali solution as the coagulation bath to obtain hollow nano-heterosomes. chemical fiber. All the other processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com