Bio-based polyethylene/starch blending modified film blowing material and preparation method thereof

A blending modification and bio-based technology, which is applied in the field of bio-based polyethylene/starch blended modified blown film materials and its preparation, can solve the problem of mechanical performance degradation, low bio-based content of starch/polyethylene plastic materials, unfavorable Problems such as popularization and application, to achieve the effect of lowering melt index, improving production performance and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

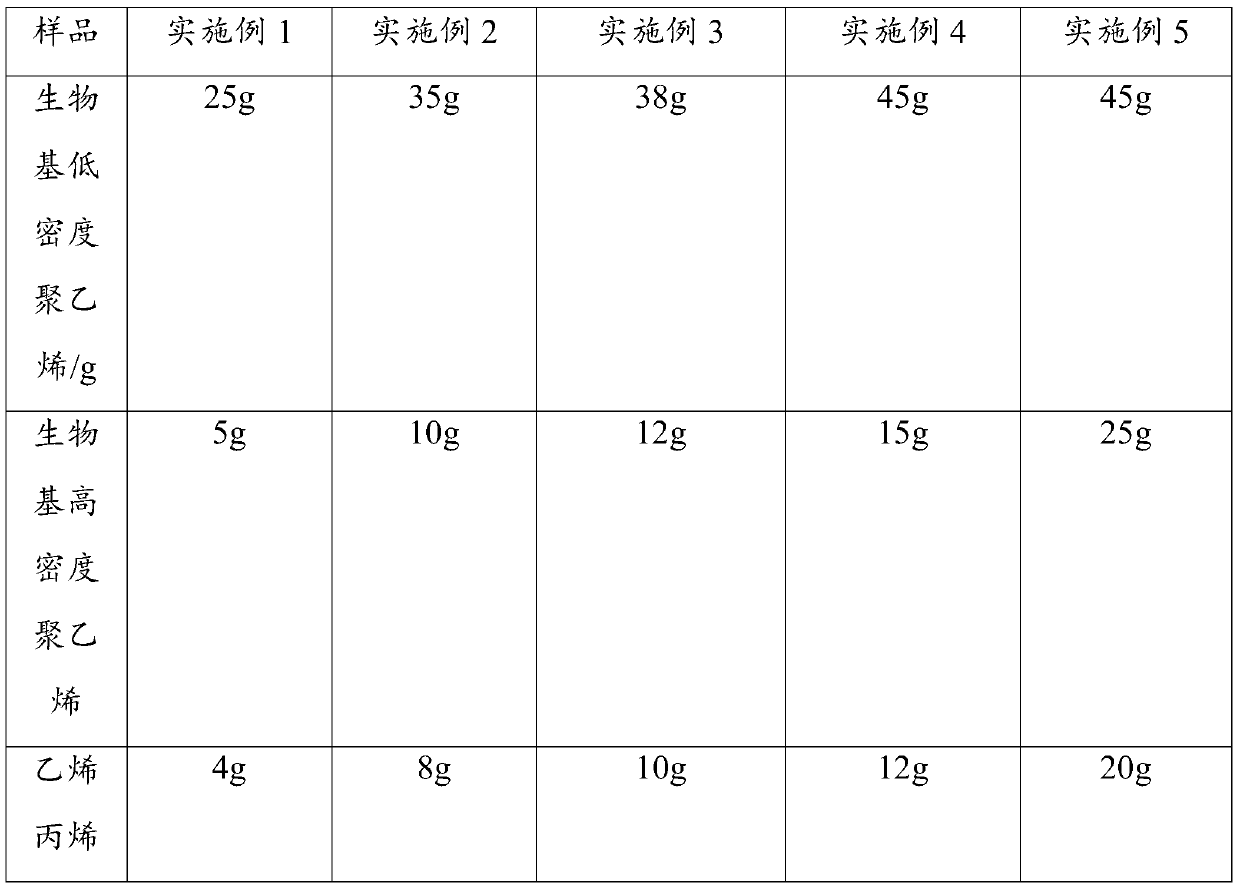

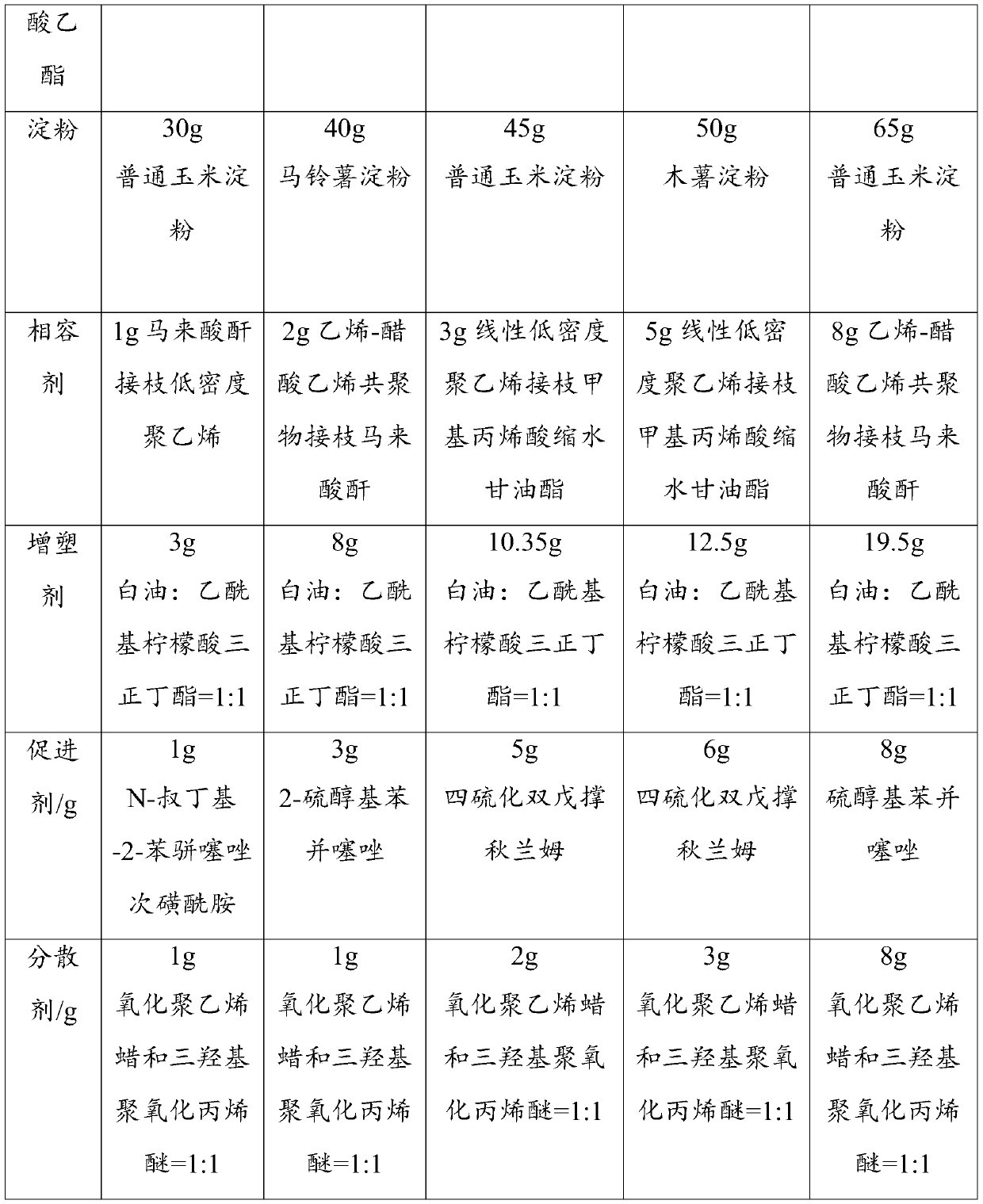

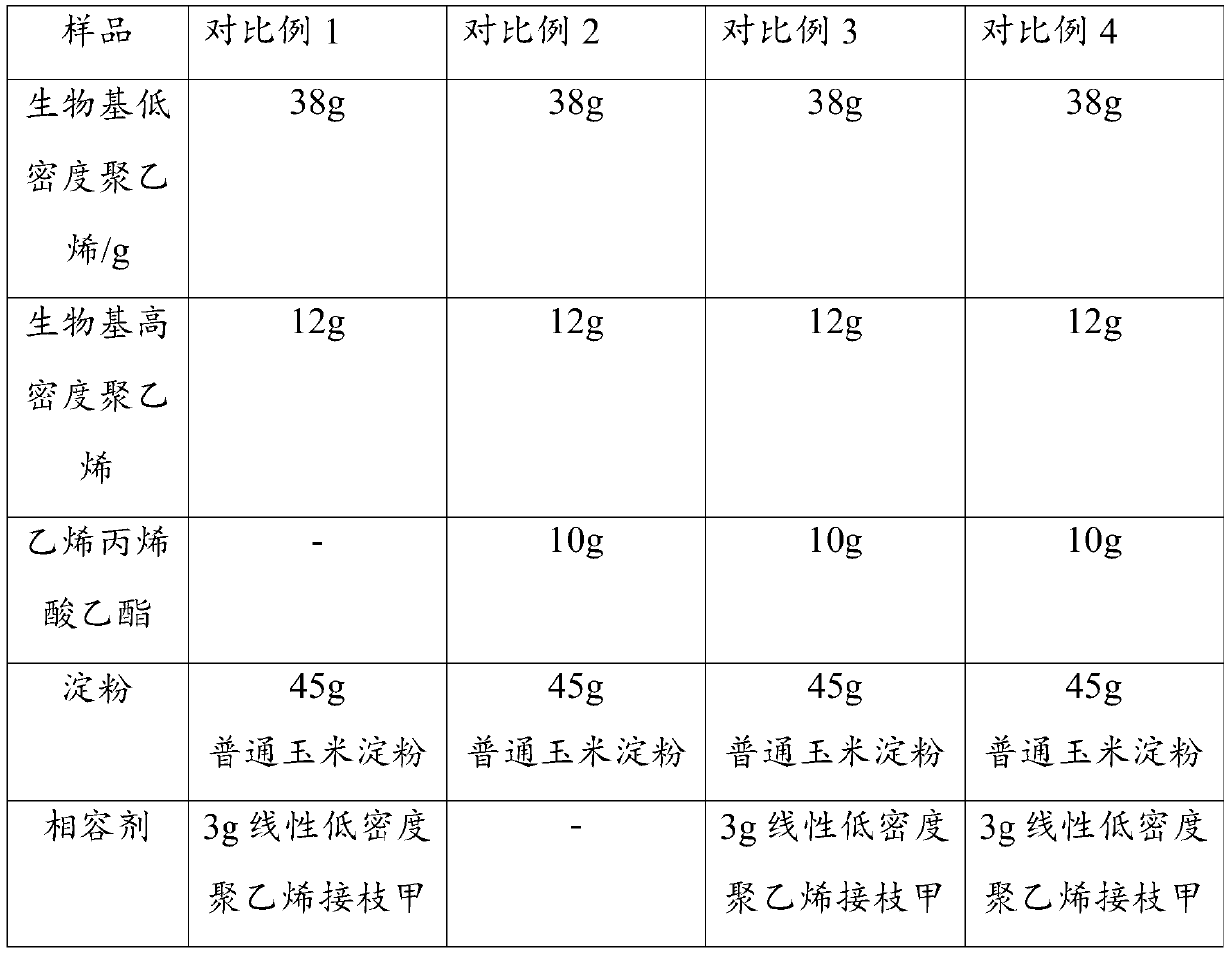

[0030] Example 1-5 Components and preparation of polyethylene / thermoplastic starch blending modified blown film material

[0031] Examples 1-5, the components of polyethylene / thermoplastic starch blended modified blown film material are shown in the following table.

[0032] Table 1

[0033]

[0034]

[0035] Embodiment 1-5, the preparation method of polyethylene / thermoplastic starch blending modified blown film material, the steps are as follows:

[0036] S1. First add starch into the reaction kettle, set the temperature to 150°C, turn on the stirring shaft, rotate speed 800rpm / min, and time 30min, so that the starch moisture is controlled within 0.5%, and then add plasticizer through the solid feeding port at the upper end of the reaction kettle , the accelerator continues to mix for 25min to obtain thermoplastic starch;

[0037]S2. Add bio-based low-density polyethylene, bio-based high-density polyethylene, and ethylene ethyl acrylate to the reaction kettle, mix for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com