Preparation method of cellulose nanofiber

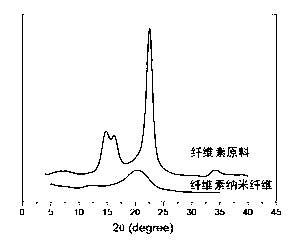

A nanofiber and cellulose technology, applied in the field of agricultural engineering, can solve the problems of inability to obtain cellulose nanofibers, and achieve the effect of improving mechanical properties, thermal properties, and excellent dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

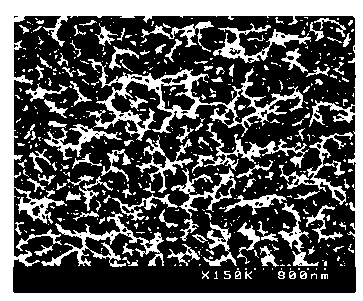

[0032] Cool the solvent system composed of 5-10wt% NaOH, 0.1-20wt% urea and the rest of water to 0-15°C, add cellulose and stir to dissolve to obtain 50g of 0.5wt% cellulose solution. Slowly add distilled water dropwise to the cellulose solution under stirring until the cellulose is completely regenerated from the solution to obtain a cellulose nanofiber suspension. The cellulose nanofiber suspension is placed in a dialysis bag and dialyzed to neutrality, and then treated with a cell disruptor for 10 minutes to obtain a cellulose nanofiber aqueous dispersion. After freeze-drying, white fluffy cellulose nanofibers were obtained.

Embodiment 2

[0034] Cool the solvent system composed of 5-10wt% NaOH, 0.1-20wt% urea and the rest of water to 0-15°C, add cellulose and stir to dissolve to obtain a 1wt% cellulose solution. Slowly add methanol dropwise to the cellulose solution under stirring until the cellulose is completely regenerated from the solution to obtain a cellulose nanofiber suspension. The cellulose nanofiber suspension is placed in a dialysis bag and dialyzed to neutrality, and then treated with a homogenizer for 10 minutes to obtain a cellulose nanofiber aqueous dispersion. After freeze-drying, white fluffy cellulose nanofibers were obtained.

Embodiment 3

[0036] Cool the solvent system composed of 5-10wt% NaOH, 0.1-20wt% urea and the rest of water to 0-15°C, add cellulose and stir to dissolve to obtain a 1wt% cellulose solution. Slowly add hydrochloric acid dropwise to the cellulose solution under stirring until the cellulose is completely regenerated from the solution to obtain a cellulose nanofiber suspension. The cellulose nanofiber suspension is placed in a dialysis bag and dialyzed to neutrality, and then treated with a homogenizer for 10 minutes to obtain a cellulose nanofiber aqueous dispersion. The white fluffy cellulose nanofibers were obtained by replacing the water with ethanol and drying at the critical point.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com