Method for making aqueous polyurethane elastic suede leather

A water-based polyurethane and suede technology, applied in textiles and papermaking, can solve problems such as human injury and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

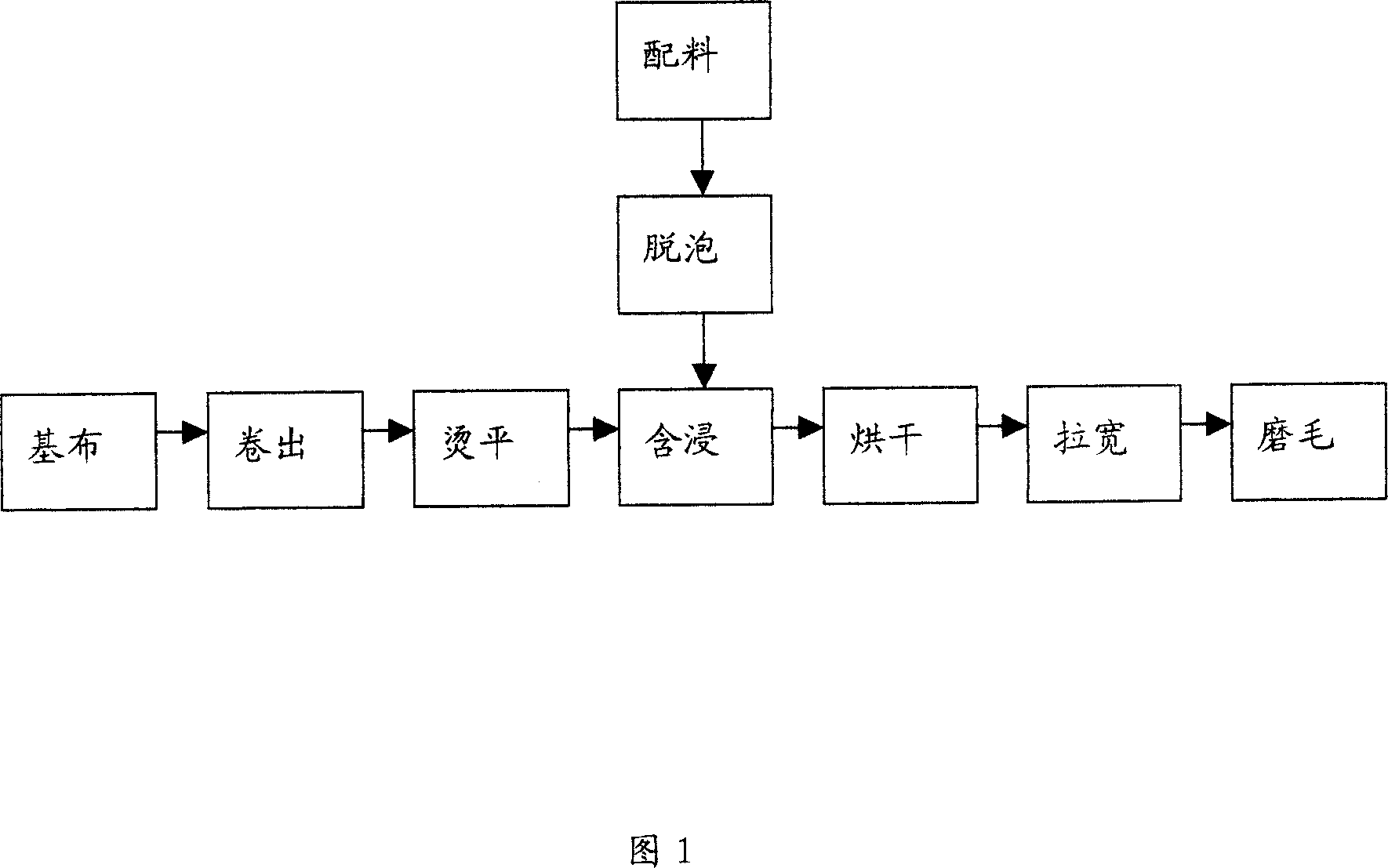

Method used

Image

Examples

Embodiment 1

[0029] 1. Ingredients

[0030] Waterborne polyurethane: UL-5020, solid content 20%, 100 parts;

[0031] Pure water: 10 parts;

[0032] Water-based colorant: orange-10 1.0 parts;

[0033] Thickener: 0.5 parts of HEUR-C;

[0034] 2. Impregnation speed: 5 m / min.

[0035] 3. Drying temperature: 120°C.

[0036] 4. Gap between impregnated rollers: 0.5mm.

Embodiment 2

[0038] 1. Ingredients

[0039] Waterborne polyurethane: UL-5020, solid content 20%, 100 parts;

[0040] Pure water: 50 parts;

[0041] Water-based colorant: orange-10 0.5 part;

[0042] Thickener: 0.3 parts of HEUR-C;

[0043] 2. Impregnation speed: 5 m / min.

[0044] 3. Drying temperature: 120°C.

[0045] 4. Gap between the impregnation rollers: 0.6mm.

Embodiment 3

[0047] 1. Ingredients

[0048] Waterborne polyurethane: UL-5020, solid content 20%, 100 parts;

[0049] Pure water: 100 parts;

[0050] Water-based colorant: orange-10 0.5 parts;

[0051] Thickener: 0.2 parts of HEUR-C;

[0052] 2. Impregnation speed: 5 m / min.

[0053] 3. Drying temperature: 120°C.

[0054] 4. Gap between the impregnation rollers: 0.6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com