Heat-insulation anti-ultraviolet automobile membrane and preparation method thereof

A car film and anti-ultraviolet technology, which is applied in the field of heat-insulating and anti-ultraviolet car film and its preparation, and can solve the problems of reduced mechanical strength, high cost, and complicated process of polyvinyl chloride film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

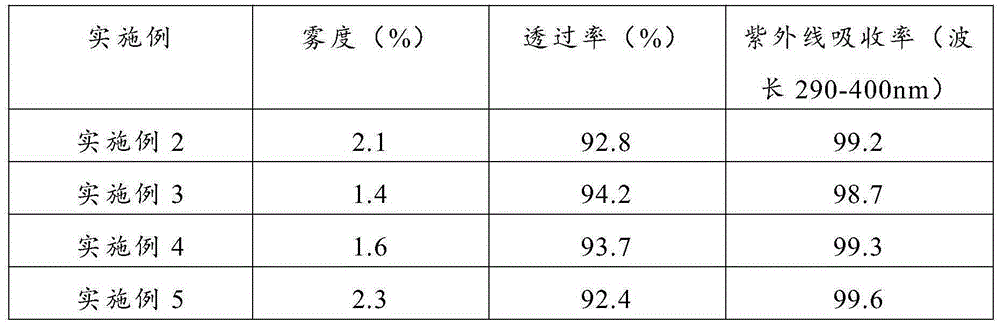

Examples

preparation example Construction

[0021] The embodiment of the present invention discloses a preparation method of an anti-ultraviolet and anti-aging nanocomposite material, comprising the following steps: dispersing 5-10 parts of nano-zinc oxide into absolute ethanol, then adding 10-15 parts of cerium chloride, stirring Obtain the first mixed solution; Add acetylacetone dropwise to the first mixed solution, place it after sealing and stirring, centrifuge, wash and dry to obtain zinc oxide coated with nano-cerium dioxide; Zinc oxide of cerium is dispersed in the mixed solution of deionized water and absolute ethanol, add 5-15 parts of low molecular weight sodium polyacrylate, then drop 3-6 parts of silane coupling agent, adjust the pH value to 9-10 after stirring After ultrasonic dispersion, continue to stir for 30-40 minutes, centrifuge and dry to obtain anti-ultraviolet and aging-resistant nanocomposites.

[0022] In the above technical scheme, the present invention utilizes the sol-gel method to coat a laye...

Embodiment 1

[0056] This embodiment provides a method for preparing an anti-ultraviolet and anti-aging nano-composite material, in parts by weight, comprising the following steps:

[0057] Disperse 8 parts of nano zinc oxide into 200 parts of absolute ethanol, then add 15 parts of cerium chloride, and stir for 10 minutes.

[0058] Then 3-5 parts of acetylacetone are added dropwise to the above-mentioned solution, stirred at room temperature for 2 hours, and aged for 2 hours to obtain zinc oxide (ZnOCeO2) coated with nano-cerium dioxide. 2 ).

[0059] The above ZnOCeO 2 Centrifuge, repeatedly add 1,2 propylene glycol and ethanol to wash, and dry.

[0060] The above prepared ZnOCeO 2 Disperse in a mixed solution of 100 parts of deionized water and 200 parts of absolute ethanol.

[0061] Add 12 parts of low-molecular-weight sodium polyacrylate, then dropwise add 5 parts of silane coupling agent, stir thoroughly for 10 minutes, adjust the pH of the solution to 9-10, ultrasonicate for 5 min...

Embodiment 2

[0063] This embodiment provides a method for preparing a heat-insulating and anti-ultraviolet automotive film, in parts by weight, comprising the following steps:

[0064] 1. Mix 60 parts of polyethylene terephthalate, 15 parts of polytrimethylene terephthalate, 8 parts of polyimide, 9 parts of molybdenum disulfide, 10 parts of plasticizer and 2-3 parts of ethylene- Put the α-olefin copolymer into a high-speed mixer and stir for 10-20 minutes at 800-1100 rpm.

[0065] 2. Heat the above mixture to 105°C, add 5 parts of carboxymethyl cellulose and 8 parts of nano silicon dioxide, and continue to stir for 25 minutes.

[0066]3. Add the mixture obtained in step 2 into a twin-screw extruder for melt blending, extrusion, cooling, and granulation to obtain film masterbatches. The blending and extrusion temperature of the twin-screw extruder is: 175°C in the first zone, The second zone is 180°C, the third zone is 19°C, the fourth zone is 205°C, the fifth zone is 215°C, the head is 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com