Blending fire retardant -type terylene industrial filament and its manufacturing technique

A production process and flame-retardant technology, which is applied in the field of polyester industrial filaments, and can solve the problem of the blank of flame-retardant polyester industrial filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiment of the present invention: blending flame-retardant polyester industrial filaments is obtained by blending and modifying inorganic flame retardant masterbatches, and the mass percentage distribution of flame retardant masterbatches and polyester masterbatches is as follows:

[0023] Polyethylene terephthalate 90-95%;

[0024] Inorganic flame retardant masterbatch 5.0-10.0%.

[0025] The inorganic flame retardant masterbatch contains 20%-30% of aluminum hydroxide, magnesium hydroxide or zinc borate inorganic flame retardant, and 70%-80% of polyester, calculated by mass percentage.

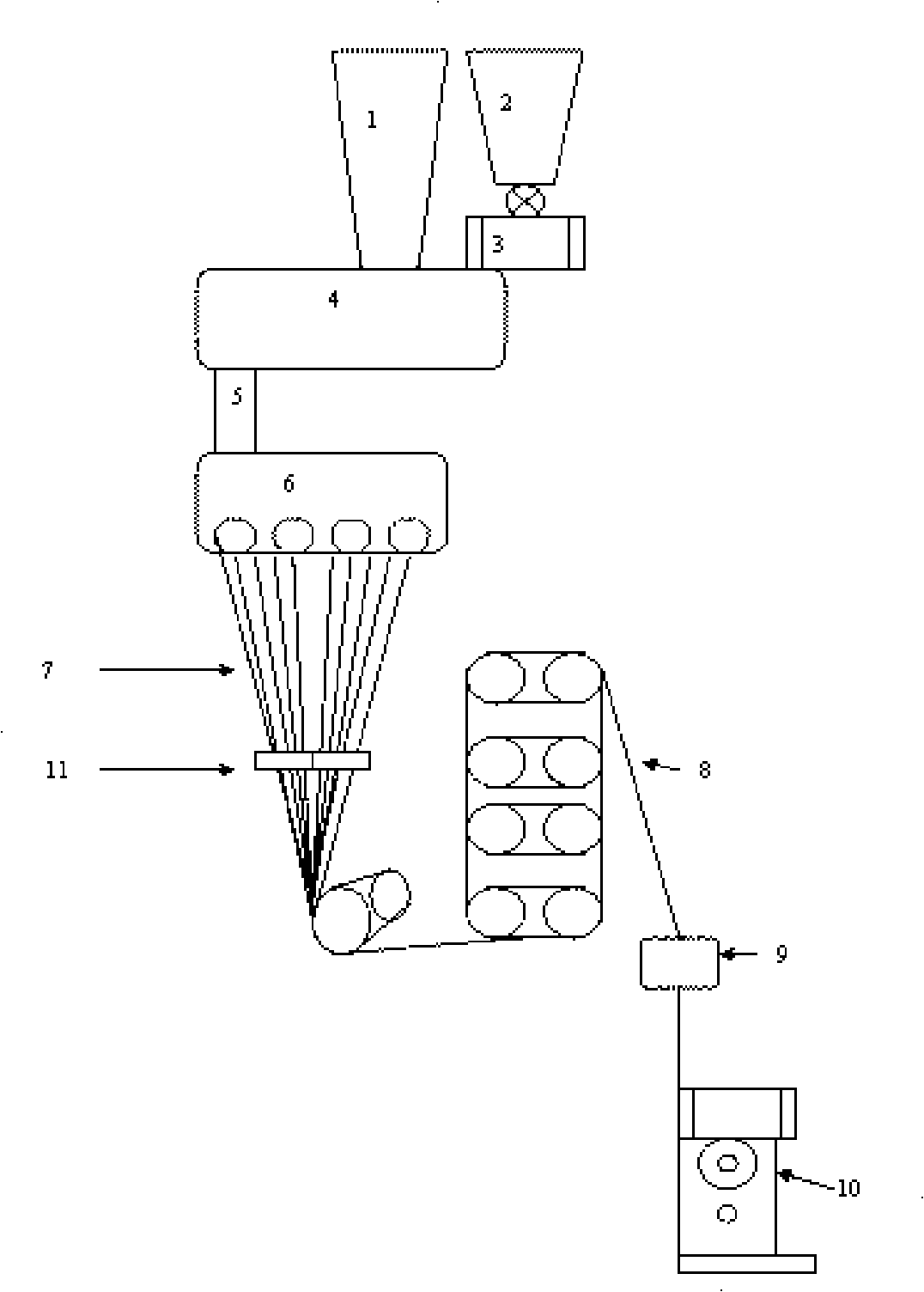

[0026] The production process of the described copolymerized flame-retardant polyester industrial filament includes solid phase polymerization, spinning and drawing heat setting process, such as figure 1 As shown, the specific steps are described as follows:

[0027] A. Solid-state polymerization: Feed low-viscosity polyester chips with a conventional original viscosity between 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com