Application of polyamide 5X as flame-retardant material

A flame retardant material and polyamide technology, which is applied in the application field of polyamide 5X as a flame retardant material, can solve the problems of unusability, corrosion, and insignificant effect, and achieve the effect of increasing the number of washings and good flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

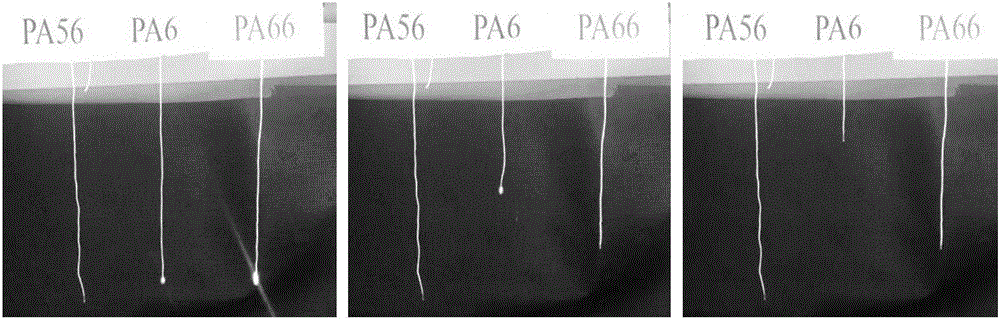

Image

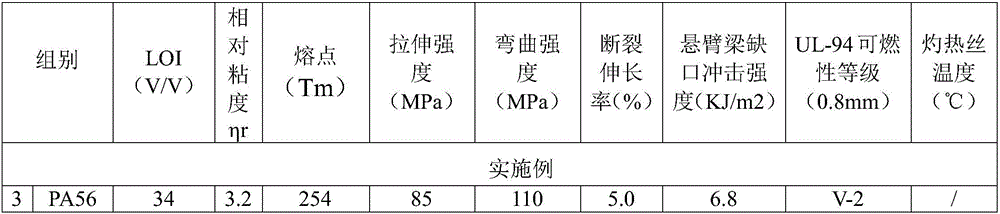

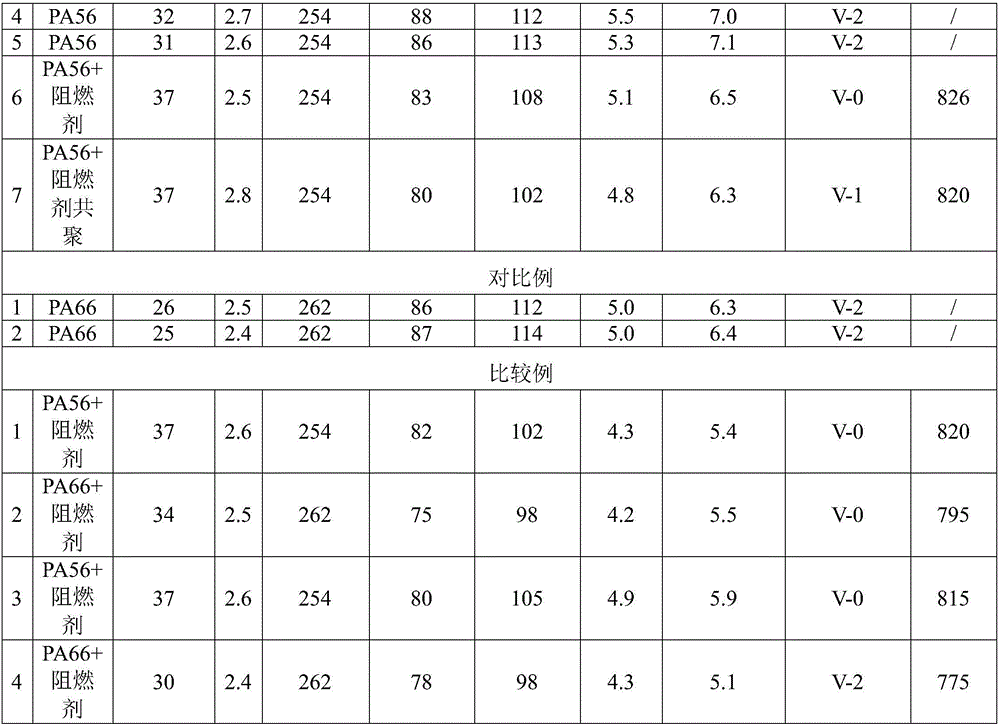

Examples

Embodiment 1

[0102] 1,5-Pentanediamine bioproduction:

[0103] The lysine fermentation stock solution is added in the reaction tank of 1000 liters, and the lysine content is 11%; The SO in the lysine fermentation stock solution 4 2- The concentration is about 0.23mol / kg, which also contains sugar and free NH 4 + , total sugar content 350ppm, free NH 4 + The content is 0.032mol / kg. Add lysine decarboxylase cell and coenzyme (5 '-pyridoxal phosphate) in this lysine fermentation stock solution again, decarboxylase cell addition and lysine weight ratio 0.021 in the lysine fermentation stock solution, coenzyme concentration ( The ratio of the amount of coenzyme added to the weight of all reaction materials except coenzyme) is 0.15mmol / kg; the reaction is stirred at 36°C for 2h; the content of pentamethylenediamine in the solution after the reaction is 61.5g / kg.

Embodiment 2

[0104] Embodiment 2 mixed fermentation

[0105] The Escherichia coli strain with the preservation number CCTCC M 2013100 was cultured in a shaker flask. The shaker flask was 500ml, the liquid volume was 30ml, the shaker speed was 180rpm, the fermentation temperature was 35°C, and the formula of the fermentation medium was as follows. The initial pH of the fermentation was 7.0. After inoculation, culture was carried out for 50 hours, and the strain Hafnia alvei which was capable of producing lysine decarboxylase produced by Kaiser Company was inserted, and the culture was continued at 30° C. for 30 hours.

[0106] Component

[0107] After the fermentation was finished, the content of 1,5-pentanediamine in the fermentation broth was determined to be 5.3 g / L.

Embodiment 3

[0109] Preparation of polyamide 56:

[0110] (1) Mix adipic acid, 1,5-pentanediamine and water evenly in the reactor, wherein the weight of dibasic acid and diamine accounts for 50% of the total weight of the solution, take a small amount of salt solution and dilute to 10 %Detected at 25°C, the pH value was 8.03, and made a polyamide 56 salt solution with a mass percentage concentration of 50%;

[0111] (2) Add 40ppm of heat stabilizer sodium hypophosphite (accounting for the total weight of dibasic acid and diamine) to polyamide 56 salt solution to obtain polyamide 56 salt mixed solution. Concentrated to a concentration of 75% under conditions;

[0112] (3) Heating the system, gradually increasing the pressure to 1.0MPa, and maintaining the pressure for prepolymerization until the system temperature reaches 250°C;

[0113] (4) gradually reduce pressure to normal pressure, and the system temperature reaches 285 ° C;

[0114] (5) The system is maintained at normal pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com