Polyamide 56 material prepared from bio-based 1,5-pentamethylene diamine

A technology of polyamide and pentamethylene diamine, which is applied in the field of polyamide materials, can solve the problems affecting the application of flame-retardant polyamide materials, the high cost of flame-retardant materials, and the increase of potential safety hazards, and achieves wide industrial application prospects and excellent resistance. Burning effect, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

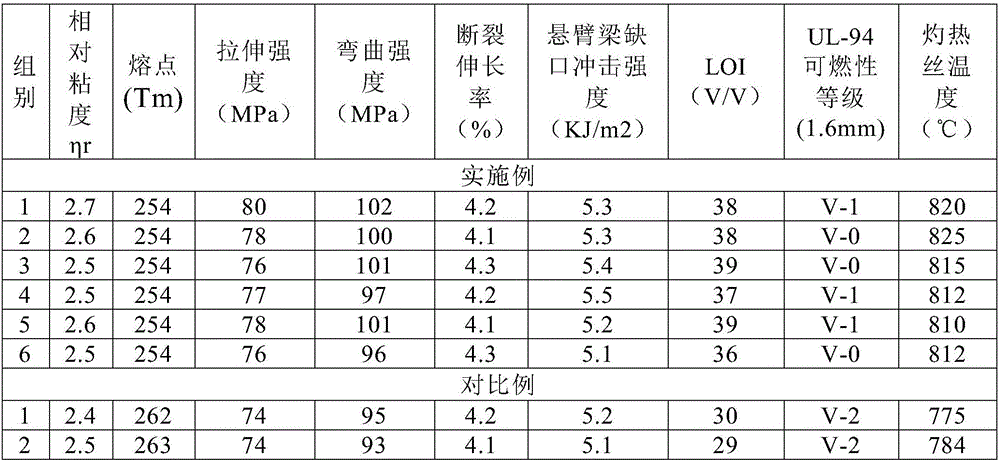

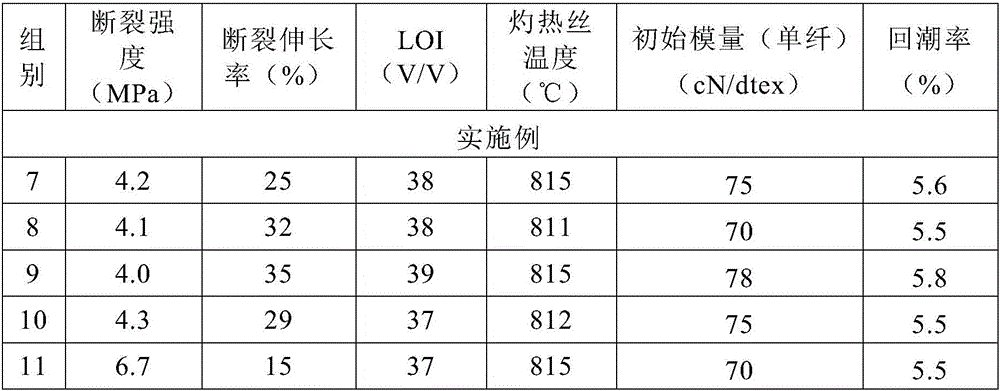

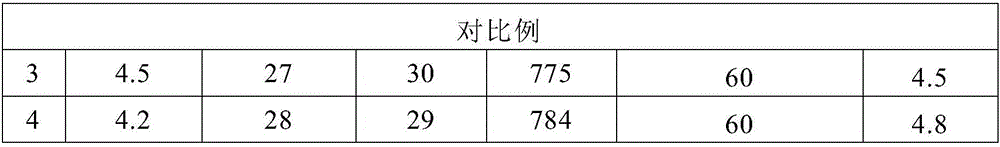

Examples

Embodiment 1

[0086] The preparation of embodiment 1 polyamide 56 flame retardant material

[0087] (1) Mix adipic acid, 1,5-pentanediamine, melamine cyanurate (MCA) and water in the reactor evenly, wherein the weight sum of dibasic acid and diamine accounts for 50% of the total weight of the solution %, take a small amount of salt solution and dilute to 10% and detect that the pH value is 8.22 at 25°C to make a polyamide 56 salt solution with a mass percent concentration of 50%; wherein, the addition of MCA is 3% (percentage is 3% of polyamide 56% by mass of flame retardant material);

[0088] (2) The polyamide 56 salt solution is concentrated to a polymer concentration of 80% under the conditions of a pressure of 0.3 MPa and a temperature of 120°C;

[0089] (3) Heating the system, gradually increasing the pressure to 1.8MPa, and maintaining the pressure for prepolymerization until the system temperature reaches 245°C;

[0090] (4) Gradually reduce the pressure until the vacuum degree re...

Embodiment 2

[0094] Preparation of embodiment 2 polyamide 56 flame retardant material

[0095] (1) Mix adipic acid, 1,5-pentanediamine, melamine phosphate and water in the reactor, wherein the sum of dibasic acid and diamine accounts for 60% of the total weight of the solution, and both The molar ratio is 1:1.1, and the addition amount of melamine phosphate is 5% (the percentage is the mass percentage accounting for the polyamide 56 flame retardant material);

[0096] (2) The polyamide 56 salt solution is concentrated to a polymer concentration of 70% under the conditions of a pressure of 0.15 MPa and a temperature of 150°C;

[0097] (3) Heating the system, gradually increasing the pressure to 1.5MPa, and maintaining the pressure for prepolymerization until the system temperature reaches 255°C;

[0098] (4) Gradually reduce the pressure until the vacuum degree reaches -0.1MPa (gauge pressure), and the system temperature reaches 275°C;

[0099] (5) The system is maintained at -0.1MPa, and...

Embodiment 3

[0102] Preparation of embodiment 3 polyamide 56 flame retardant material

[0103] (1) Adipic acid, 1,5-pentanediamine, melamine polyphosphate and water are mixed uniformly in a reactor, wherein the weight sum of dibasic acid and diamine accounts for 60% of the total weight of the solution, and two The molar ratio is 1:1.1, and the addition of melamine polyphosphate is 5% (percentage is the mass percentage accounting for polyamide 56 flame retardant material);

[0104] (2) The polyamide 56 salt solution is concentrated to a polymer concentration of 80% under the conditions of a pressure of 0.1 MPa and a temperature of 120°C;

[0105] (3) Heating the system, gradually increasing the pressure to 1.6MPa, and maintaining the pressure for prepolymerization until the system temperature reaches 250°C;

[0106] (4) Gradually reduce the pressure until the degree of vacuum reaches -0.09MPa (gauge pressure), and the system temperature reaches 240°C;

[0107] (5) The system is maintained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com