Polyamide 1012 serial thermoplastic elastomer material and preparation method thereof

A polyamide, C1-C18 technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of increased cost, harsh open-loop conditions, high product cost, etc., to achieve reduced production cost, good comprehensive performance, and good solvent resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] On the one hand, a polyamide 1012 series copolymer, the copolymer is a block copolymer formed of polyamide 1012 and polyether / polyester, and its molecular chain structure repeating unit is (A) or (B):

[0043]

[0044] Among them, n is an integer from 1 to 20, R 1 , R 3 C respectively 1 -C 18 Alkyl, R 2 , R 4 are respectively polyether units or polyester units, and X is an O atom or an N atom.

[0045] Preferably, n is an integer of 1-10.

[0046] The polyamide 1012 unit can be either carboxy-terminated or amino-terminated.

[0047] In one embodiment, in the copolymer molecule, the number average molar mass of the polyamide 1012 block is 500-5000 g / mol.

[0048] In another embodiment, in the copolymer molecule, the number average molar mass of the polyamide 1012 block is 500-2500 g / mol.

[0049] In the polyamide 1012 series copolymer of the present application, polyamide is used as a hard segment, and in order to adjust the molar mass of the hard segment, dic...

Embodiment 1

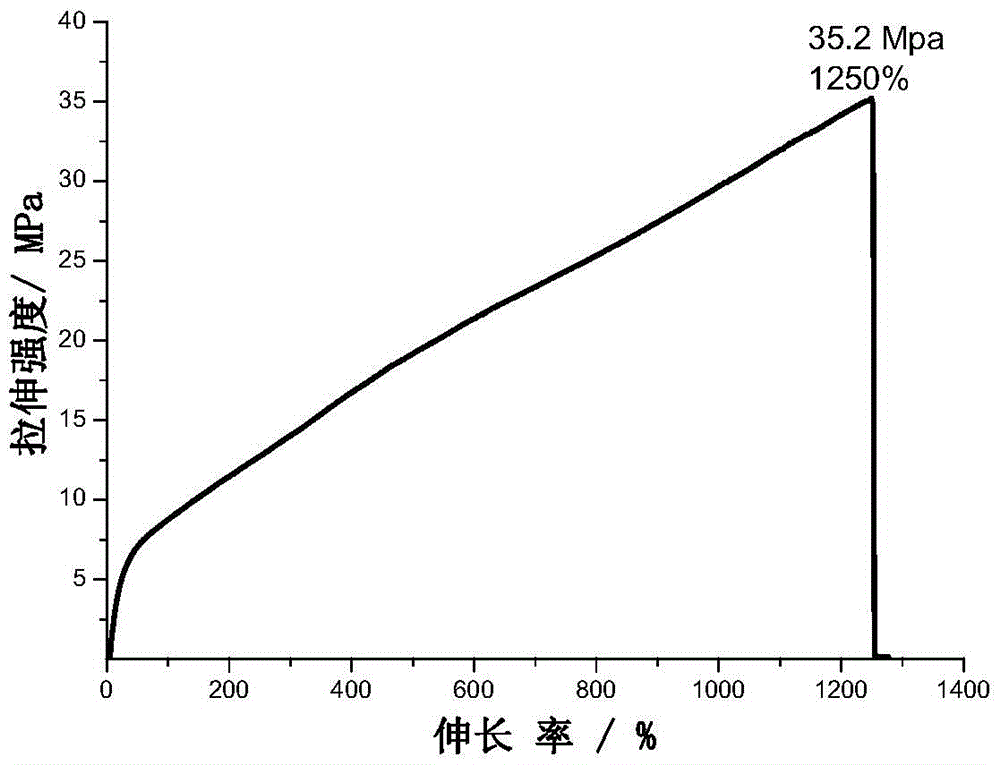

[0094] Add 7.20 g of dodecyl dibasic acid and 2.59 g of decanediamine into the reaction vessel, replace the air in the reaction vessel with nitrogen flow for 5 minutes, heat to 260° C. under nitrogen flow atmosphere, and turn off the nitrogen flow after 40 minutes. Keep the reaction vessel in a closed state, and react at 260°C for 2h. Then evacuate to reduce the pressure in the container, keep the pressure constant for 30min, and then stop evacuating. 10.68 g of polytetrahydrofuran glycol PTMEG2000 and 0.005 g of titanium tetraisopropoxide were added to the reaction vessel. After heating to 260°C under a nitrogen atmosphere, stir for 30 minutes, then gradually reduce the pressure in the reaction vessel to 400 Pa by vacuuming, and discharge after 6 hours of constant pressure reaction. The relative viscosity of the product is 0.11dL / g, the tensile strength is 35.2MPa, the elongation at break is 1250%, and the Shore hardness is 40D.

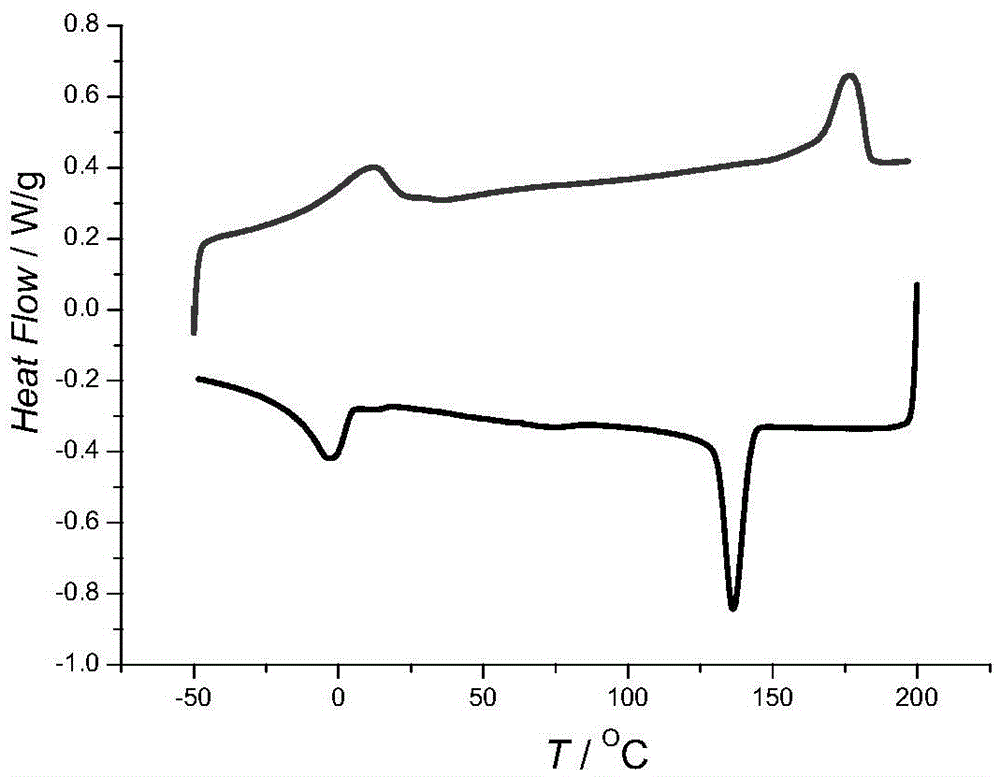

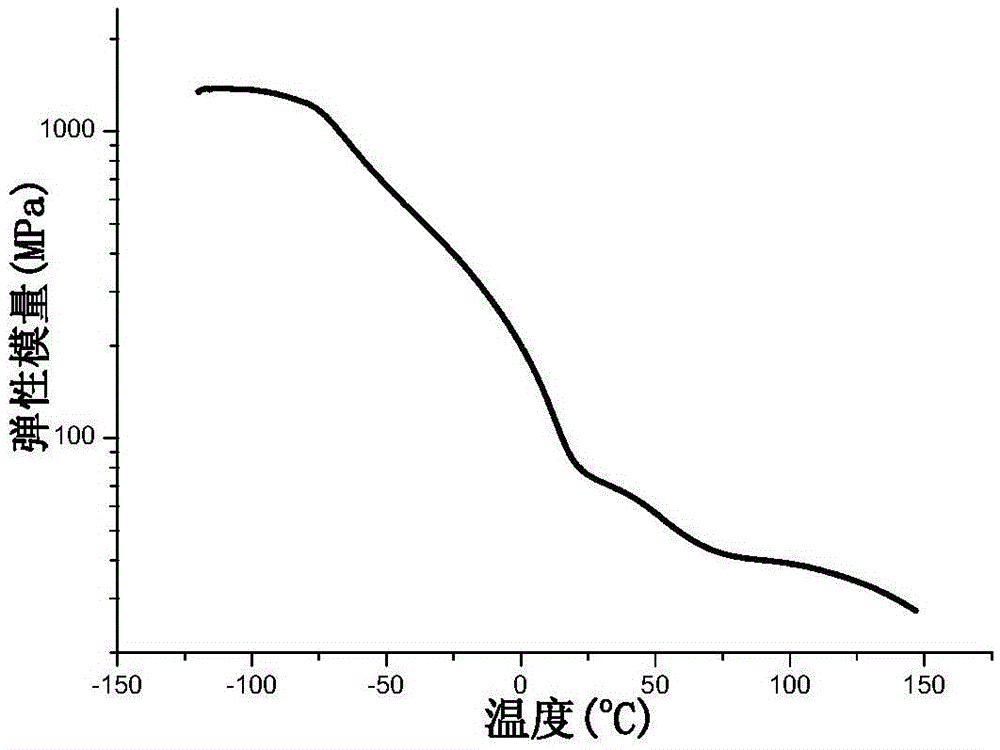

[0095] DSC test, tensile test and elastic m...

Embodiment 2

[0100] Add 7.20 g of dodecyl dibasic acid and 2.59 g of decanediamine into the reaction vessel, replace the air in the reaction vessel with nitrogen flow for 5 minutes, heat to 260° C. under nitrogen flow atmosphere, and turn off the nitrogen flow after 40 minutes. Keep the reaction vessel in a closed state, and react at 260°C for 2h. Then vacuumize to reduce the pressure in the container to 400Pa, keep the pressure constant for 30min, and then stop vacuumizing. 5.34 g of polytetrahydrofuran glycol PTMEG1000 and 0.005 g of titanium tetraisopropoxide were added to the reaction vessel. After heating to 250°C under a nitrogen atmosphere, stir for 30 minutes, then vacuumize and gradually reduce the pressure in the reaction vessel to 400 Pa, react at constant pressure for 8 hours, and discharge. The relative viscosity of the product is 0.31dL / g, the tensile strength is 38.5MPa, the elongation at break is 750%, and the Shore hardness is 55D.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com