Pretreatment method for purifying extract liquor

A technology of extraction liquid and extraction instrument, which is applied in chemical/physical processes, ion exchange treatment devices, instruments, etc., can solve the problems of high cost of analysis samples, heavy labor workload, high price, etc., to reduce the broadening of chromatographic bands, reduce Efforts to ensure effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

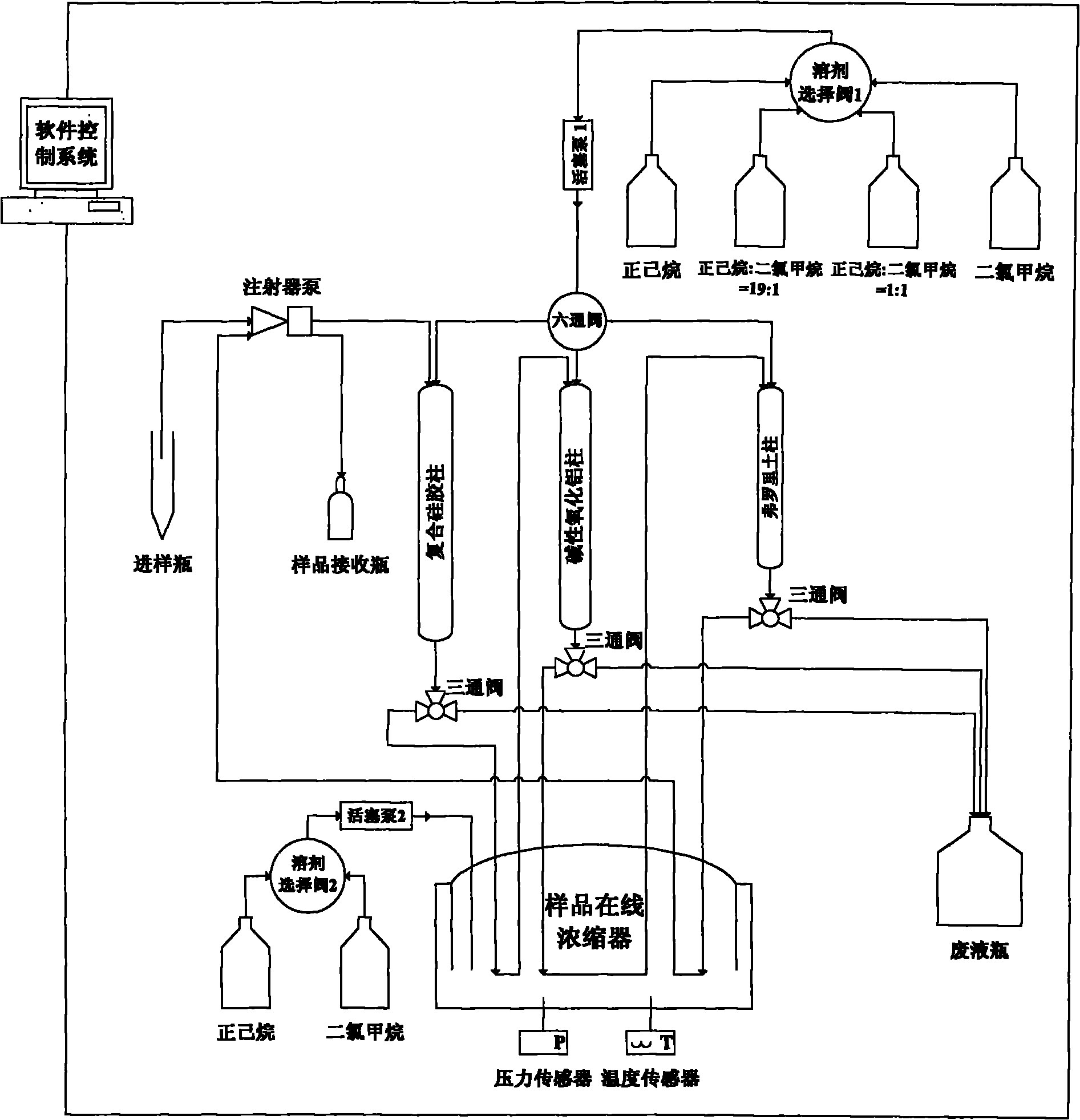

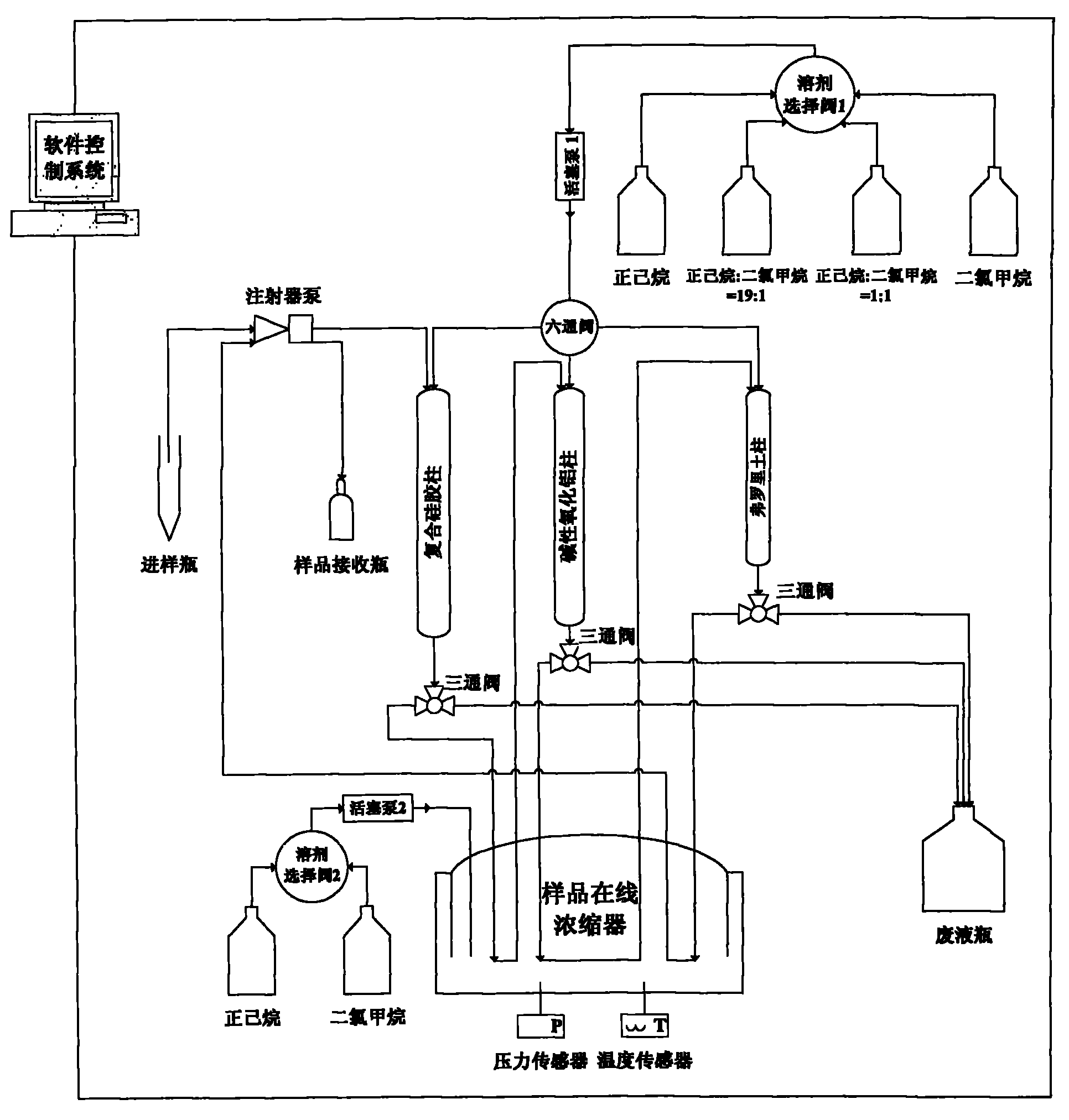

[0019] The present invention is based on automatic solid phase extraction instrument (SPE, J 2 scientific PrepLinc)'s automatic purification of PCDD / Fs, PCBs and PBDEs pre-analysis technology in sample extracts.

[0020] The technical scheme that the present invention adopts comprises following five parts:

[0021] 1) Sample purification column: including composite silica gel column (Multilayer Silica Column), basic alumina column (Basic Alumina Column), Florisil column (Florisil Column). in:

[0022] A) The composition of the composite silica gel column from bottom to top is: 0.5g silica gel, 2g basic silica gel, 0.5g silica gel, 5g acid silica gel, 1g silica gel, 0.5cm anhydrous sodium sulfate, packed in a 12ml SPE extraction column, up and down The liner sieve plate is sealed and preserved.

[0023] Among them, silica gel (0.063-0.100mm), Merck company (Darmstadt, Germany), was activated at 550 ° C for 12 hours; alkaline silica gel was dissolved in 30 ml of deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com