High-strength flame-retarding kraft board paper, preparation method and application thereof

A kraft box, high-strength technology, applied in special paper, chemical instruments and methods, paper, etc., can solve the problems of easy delamination of finished paper, poor bonding strength between layers, and large bonding force, so as to improve the strength and expand the use. range, the effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

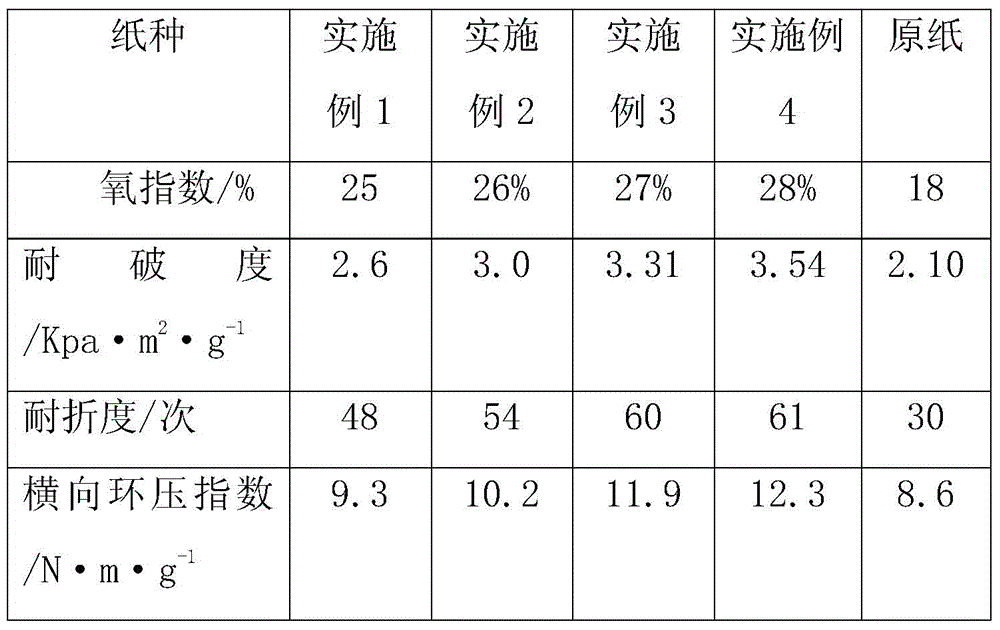

Embodiment 1

[0025] (1) Prepare a starch solution with a mass fraction of 5%, and gelatinize it for 1 hour at a temperature of 90° C. and a stirring speed of 400 r / min. Then dilute to a solution with a mass fraction of 1%.

[0026] (2) The ammonium polyphosphate solution with a mass fraction of 5% is prepared, and the ammonium polyphosphate solution is mixed with the solution with a mass fraction of 1 to 5% prepared in step (1) in a volume ratio of 1:1 to form a combined A solution for flame retardant effect and enhanced effect.

[0027] (3) Add aluminum hydroxide to the pulp in the form of additional filling during the production of container board, and make paper together with the pulp. The amount of aluminum hydroxide added is 5% of the absolute dry mass of the pulp.

[0028] (4) before the surface layer, the core layer and the bottom layer of the cardboard paper are combined, spray the mixed solution in one deck step (2) on the surface of each layer, and the consumption is 2% of the a...

Embodiment 2

[0030] (1) Prepare a starch solution with a mass fraction of 8%, and gelatinize it for 2 hours at a temperature of 95° C. and a stirring speed of 600 r / min. Then dilute to a solution with a mass fraction of 2%.

[0031] (2) The ammonium polyphosphate solution with a mass fraction of 7% is prepared, and the ammonium polyphosphate solution and the solution with a mass fraction of 1 to 5% prepared in step (1) are mixed in a volume ratio of 1:1 to form a combined A solution for flame retardant effect and enhanced effect.

[0032] (3) Add aluminum hydroxide to the pulp in the form of additional filling during the production of container board, and make paper together with the pulp. The amount of aluminum hydroxide added is 7% of the absolute dry mass of the pulp.

[0033] (4) before the surface layer, the core layer and the bottom layer of the cardboard paper are combined, spray the mixed solution in one deck step (2) on the surface of each layer, and the consumption is 4% of the ...

Embodiment 3

[0035] (1) Prepare a starch solution with a mass fraction of 10%, and gelatinize it for 3 hours at a temperature of 95° C. and a stirring speed of 700 r / min. Then dilute to a solution with a mass fraction of 4%.

[0036] (2) Prepare an ammonium polyphosphate solution with a mass fraction of 8%, mix the ammonium polyphosphate solution with the solution with a mass fraction of 1 to 5% prepared in step (1) at a volume ratio of 1:1, and mix the ammonium polyphosphate solution with both A solution for flame retardant effect and enhanced effect.

[0037] (3) Add aluminum hydroxide to the pulp in the form of additional filling during the production of container board, and make paper together with the pulp. The amount of aluminum hydroxide added is 8% of the absolute dry mass of the pulp.

[0038] (4) before the surface layer, the core layer and the bottom layer of the cardboard paper are combined, spray the mixed solution in one deck step (2) on the surface of each layer, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com