Self-rolling 3D printing integrated sprayer device capable of being used for material extrusion molding

A technology of extrusion forming and 3D printing, which is applied in coating devices, additive processing, etc., can solve the problem of poor bonding performance between layers, difficulty in popularizing and applying extrusion-molded 3D printed parts, and inability to guarantee the overall volume density of printed parts and Multi-interface performance and other issues to achieve the effect of improving interlayer bonding performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

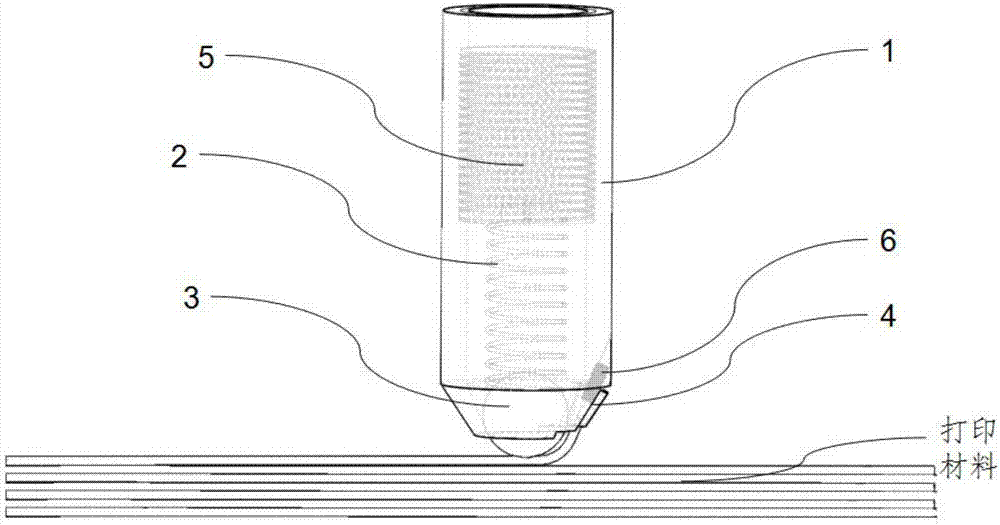

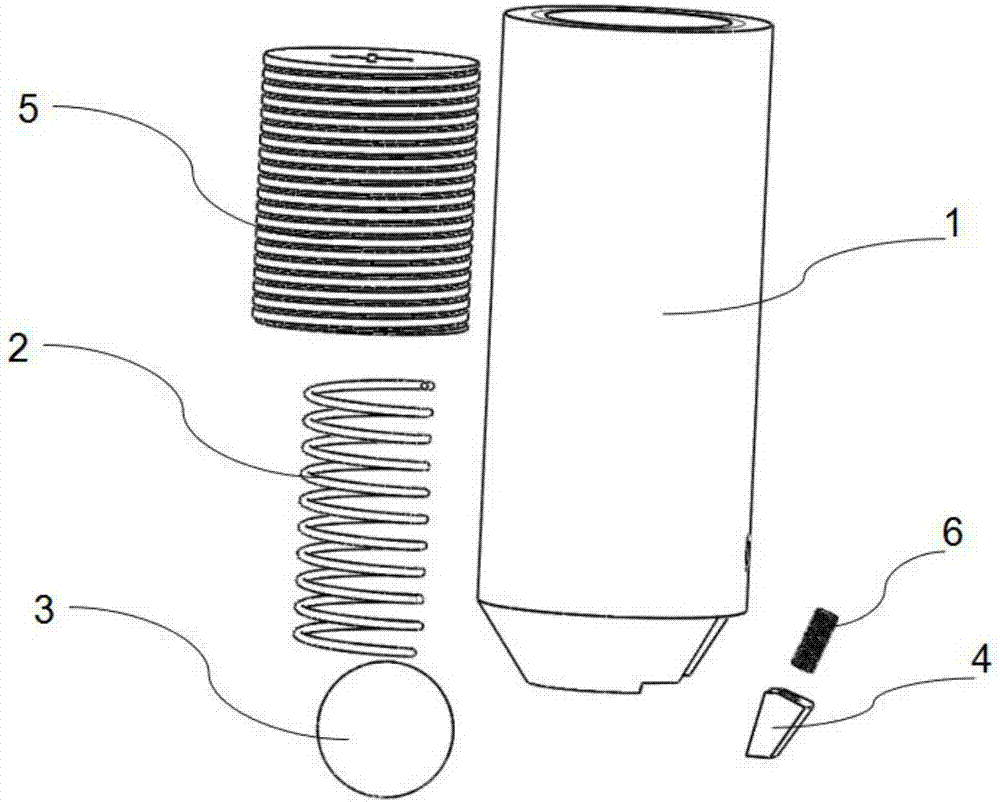

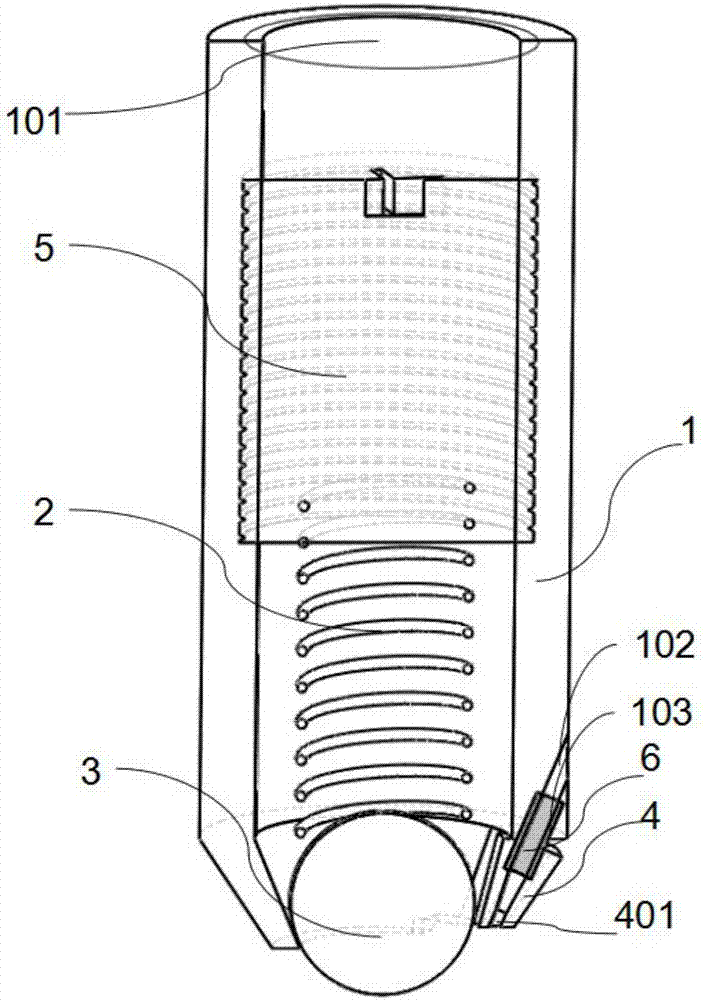

[0020] refer to figure 1 with figure 2 , a self-rolling 3D printing integrated nozzle device that can be used for material extrusion, including a printing nozzle 4, the printing nozzle 4 is fixed on the outside of the tip of the nozzle housing 1 through a nozzle fixing bolt 6, and a ball is arranged inside the tip of the nozzle housing 1 Bead 3, the upper part of the ball 3 is connected with the lower end of the spring 2, the upper end of the spring 2 is connected with the positioning bolt 5, the positioning bolt 5 is installed on the inner upper end of the nozzle housing 1, and the positioning bolt 5 is connected with the inner thread of the nozzle housing 1 The hole is matched, the ball 3 is limited by the spring 2 at the tip of the nozzle housing 1 to ensure the rotation of the ball 3, and the spring 2 is limited by the positioning bolt 5 and the internal thread hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com