Skid and scrub resistant rotationally molded product and preparation method thereof

A technology of anti-slip and rotomolding, which is applied in the direction of coating, etc., can solve the problem of low anti-slip properties, and achieve the effect of improving service life, smooth inner and outer surfaces, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

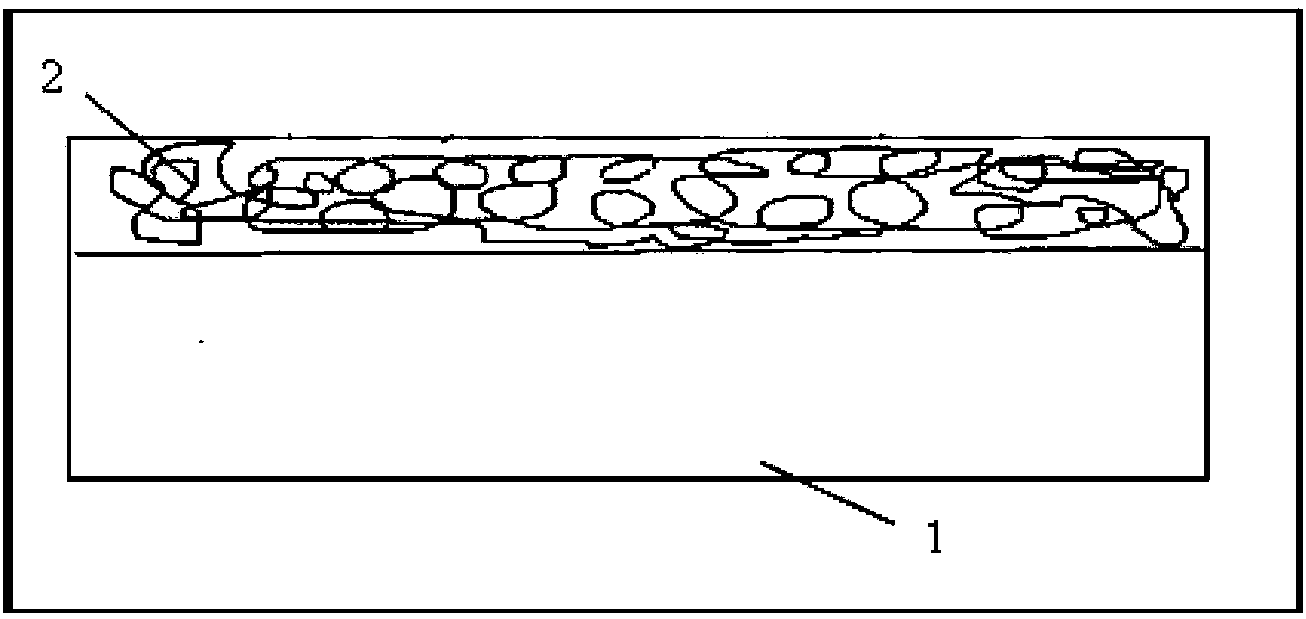

Image

Examples

preparation example Construction

[0058] Preparation method of anti-slip rotomolding composition 1:

[0059] (1) Inorganic ultra-fine wear-resistant agent treatment

[0060] Add coupling agent, dispersant and lubricant according to the formula, mix at 1000 rpm for 10 minutes, then add 5 parts of silica powder, mix for 5 minutes, discharge and set aside;

[0061] (2) Preparation of the rotomolding composition of the anti-slip layer

[0062] According to the formula, add linear low-density polyethylene, antioxidant, anti-ultraviolet agent, compatibilizer, inorganic ultra-fine wear-resistant agent, and nylon into the mixer at a speed of 1500 rpm for mixing for 10 minutes, and then use Twin-screw extrusion granulation; the temperature range of the extruder is 200°C, and the screw speed is 200 rpm. The particle size is 2.0 mm, the output is 70 kg / hour, and the particles are ground into 40-mesh powder for later use.

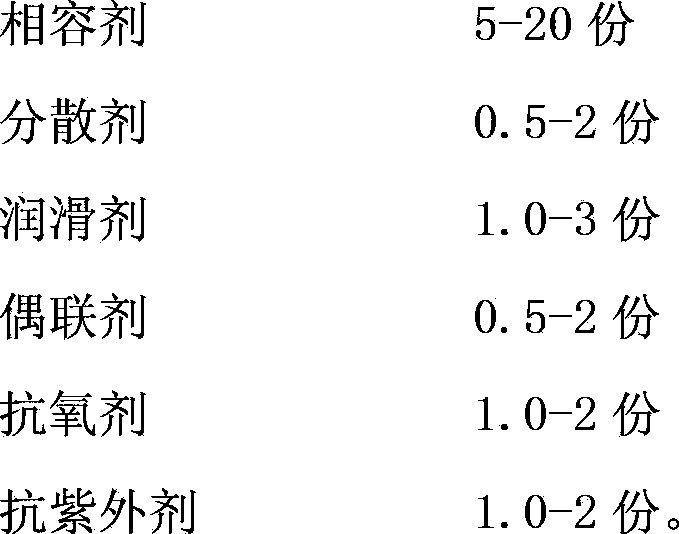

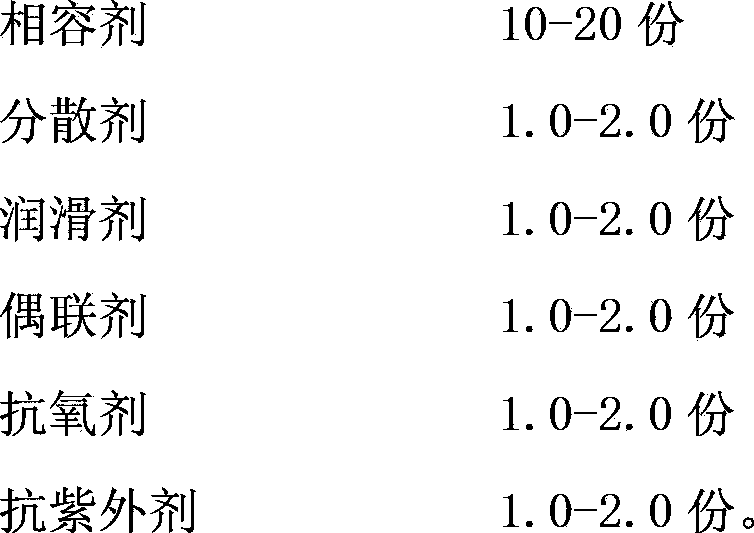

[0063] Slip resistant rotomoulding composition 2

[0064]

[0065]

[0066] Preparation m...

Embodiment 1

[0100] Example 1 LLDPE1 / slip resistance composition 1=80 / 20

Embodiment 2

[0101] Example 2 LLDPE1 / slip resistance composition 2=80 / 20

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com