Viscoelastic damping material and embedded co-curing damping composite material manufacturing technology

A damping material and viscoelastic technology, applied in the field of composite material dynamic modification process research, can solve the problems of strength and interlayer bonding performance decline, embedded co-curing damping composite material structural failure, etc., to achieve shear performance improvement, The effect of good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

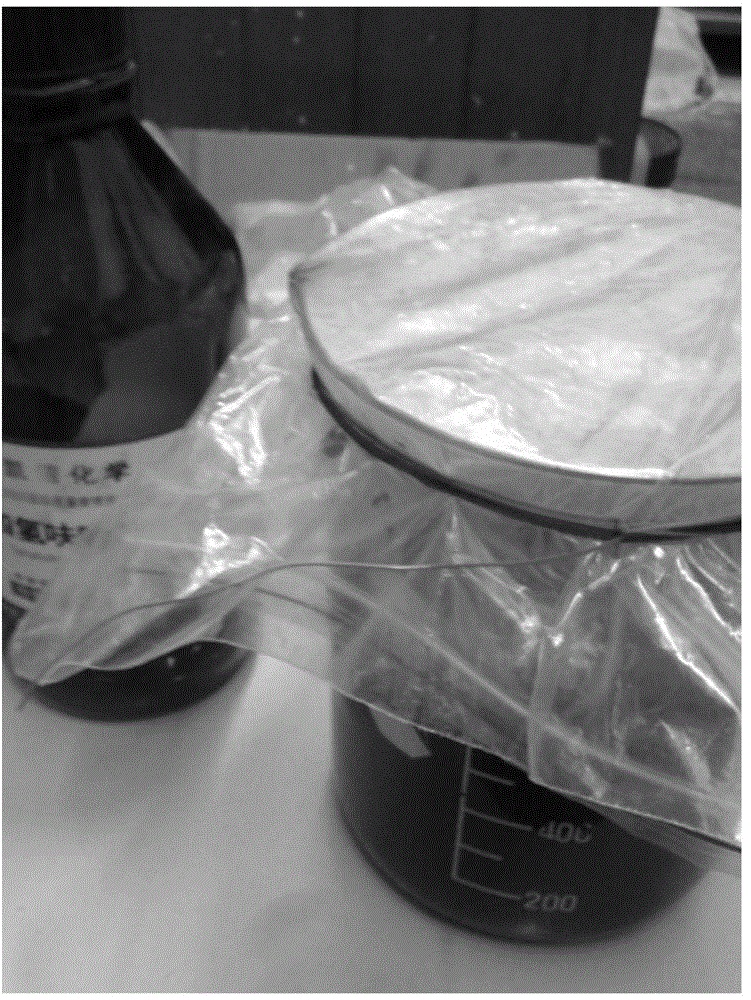

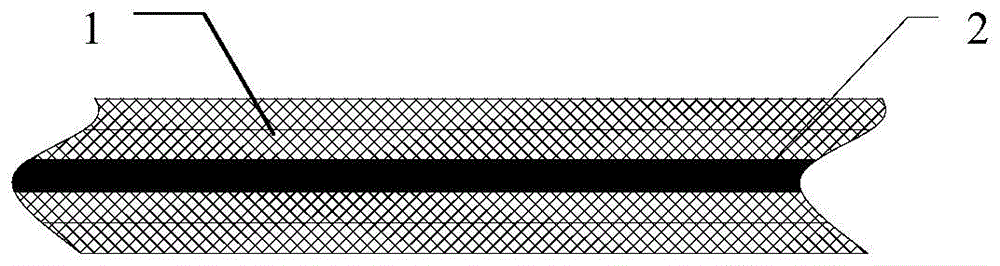

[0032] In the present invention, the rubber that can be vulcanized at high temperature is obtained by adjusting the components of the damping material, and the vulcanization curve is kept as consistent as possible with the curing curve of the carbon fiber prepreg, that is, the vulcanization temperature and vulcanization time of the fluororubber are the same as those of the corresponding composite material. The curing temperature and time of the prepreg are consistent. The interpenetrating network structure is formed through molecular bonds, so that the layers have better strength and temperature resistance. The composition of the final fluororubber obtained through the orthogonal test is shown in Table 1, so that the embedded co-cured composite structure truly has the characteristics of high damping and high temperature resistance.

[0033] Table 1 Viscoelastic materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com