Infiltration preparation method of Cu-MoCu-Cu three-layer composite plate

A cu-mocu-cu, layer composite technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of high thermal conductivity, achieve high thermal conductivity, avoid interlayer oxidation, and shorten the process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The Cu-MoCu-Cu three-layer composite sheet in this embodiment has a layer thickness ratio of 1:1:1. The Cu-MoCu-Cu three-layer composite sheet in this embodiment has the following steps:

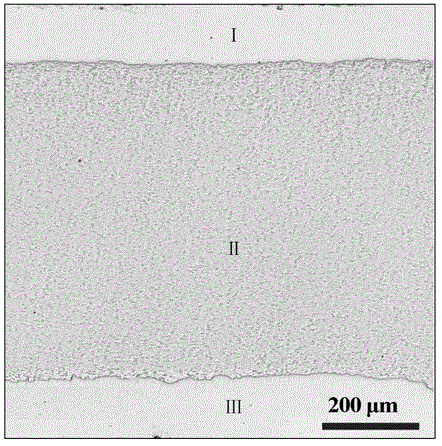

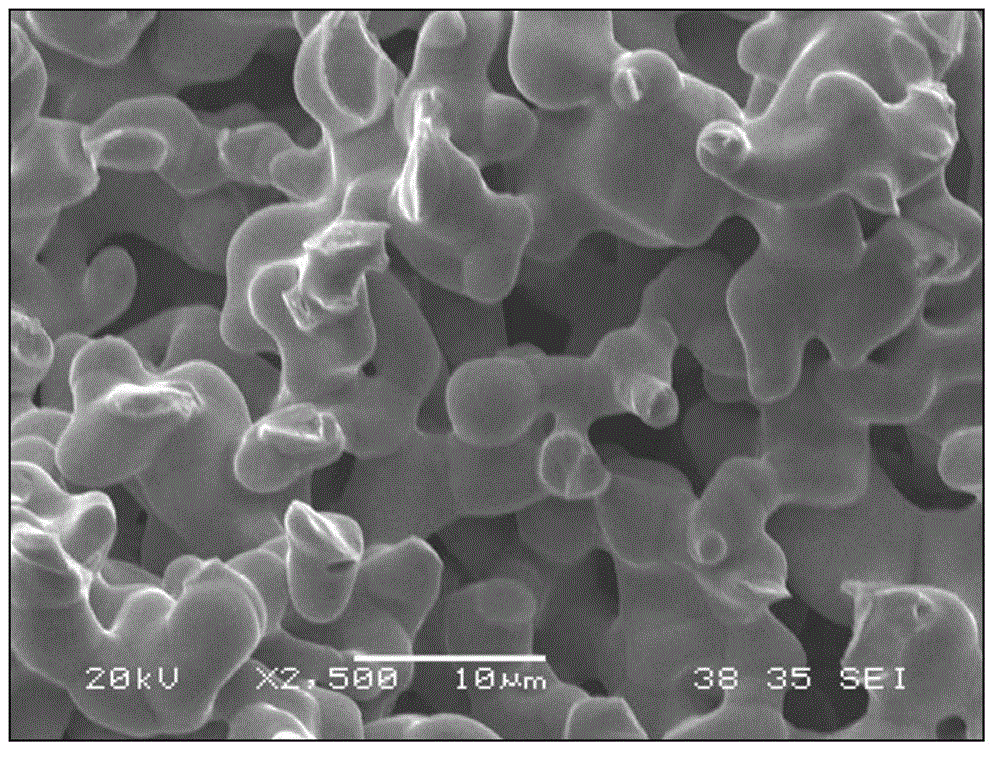

[0032] Step 1. Use a hydraulic press to press molybdenum powder with an average Fischer particle size of 5.3μm into a molybdenum slab with a thickness of 10mm, then place the molybdenum slab in a hydrogen furnace and sinter at 1500°C for 3h under the protection of a hydrogen atmosphere , Get a porous molybdenum framework with a relative density of 60%±2% (such as figure 1 Shown);

[0033] Step 2. Lay the porous molybdenum framework described in Step 1 between two oxygen-free copper plates with a thickness of 23mm, and then place them in a hydrogen furnace. Under the protection of a hydrogen atmosphere, infiltrate at 1350°C for 2 hours to obtain a complete surface. Cu-MoCu-Cu three-layer composite material coated with copper; the mass percentage of copper in the MoCu layer of the Cu-MoCu-Cu...

Embodiment 2

[0041] The Cu-MoCu-Cu three-layer composite sheet in this embodiment has a layer thickness ratio of 1:2:1. The Cu-MoCu-Cu three-layer composite sheet in this embodiment is prepared by infiltration and includes the following steps:

[0042] Step 1. Use a hydraulic press to press molybdenum powder with an average Fischer particle size of 5μm into a molybdenum slab with a thickness of 8mm, and then place the molybdenum slab in a hydrogen furnace and sinter it at 1600°C for 3h under the protection of a hydrogen atmosphere. Obtain a porous molybdenum framework with a relative density of 70%±2%;

[0043] Step 2. Lay the porous molybdenum framework described in step one between two oxygen-free copper plates with a thickness of 10mm, and then place it in a hydrogen furnace, under the protection of a hydrogen atmosphere, infiltrate at 1350°C for 2 hours to obtain a complete surface Cu-MoCu-Cu three-layer composite material coated with copper; the mass percentage of copper in the MoCu layer ...

Embodiment 3

[0051] The Cu-MoCu-Cu three-layer composite sheet in this embodiment has a layer thickness ratio of 1:3:1. The Cu-MoCu-Cu three-layer composite sheet in this embodiment is prepared by infiltration and includes the following steps:

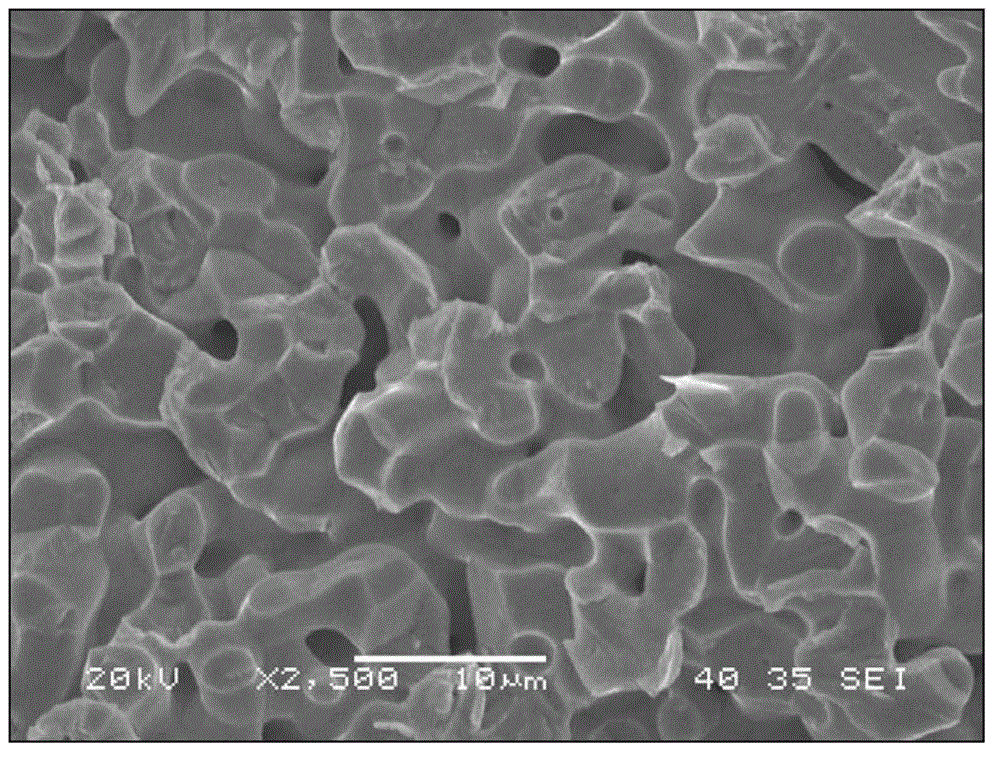

[0052] Step 1. Use a hydraulic press to press molybdenum powder with an average Fischer particle size of 5.7μm into a molybdenum slab with a thickness of 5mm, then place the molybdenum slab in a hydrogen furnace and sinter at 1700°C for 2h under the protection of a hydrogen atmosphere , Get a porous molybdenum framework with a relative density of 80%±2% (such as figure 2 Shown);

[0053] Step 2. Lay the porous molybdenum framework described in step one between two oxygen-free copper plates with a thickness of 5mm, and then place it in a hydrogen furnace, under the protection of a hydrogen atmosphere, infiltrate at 1300°C for 1.5 hours to obtain the surface Cu-MoCu-Cu three-layer composite material completely covered by copper; the Cu-MoCu-Cu three-laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com