Carbon based composited material helical spring and production method thereof

A carbon-based composite material, carbon composite material technology, applied in springs, low internal friction springs, springs/shock absorbers, etc., can solve problems such as low rigidity and poor spring structure capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A carbon-based composite coil spring production method, it comprises the following steps:

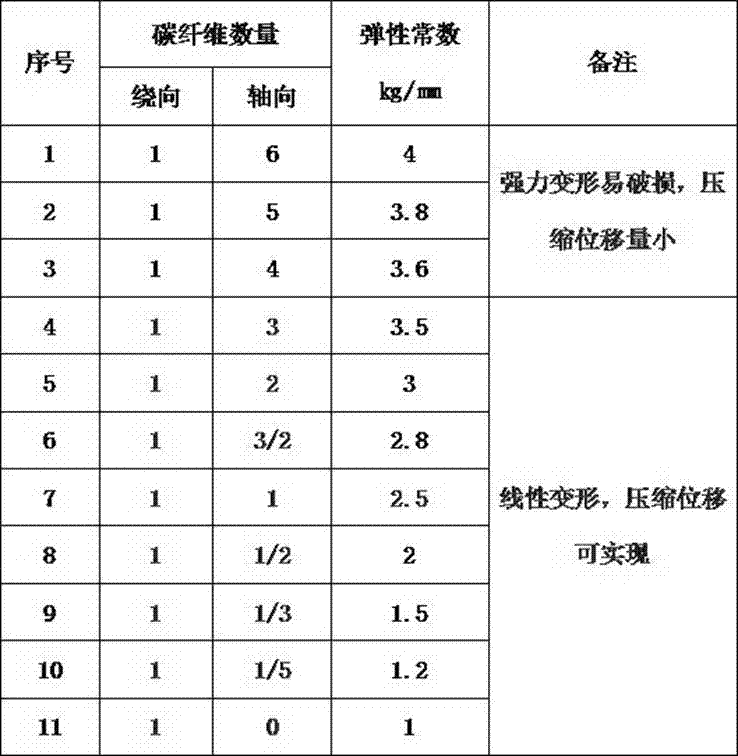

[0024] (1) Blank making: first wind the carbon fiber bundle or carbon fiber cloth with the width of the spring pitch on the mandrel along the helical direction of the spring, and the direction of the continuous long fibers of the carbon fiber bundle or carbon fiber cloth is consistent with the helical direction of the spring, and then, Wrap the carbon fiber mesh tire on the mandrel, perform acupuncture along the radial direction of the mandrel, and introduce Z-direction carbon fiber; repeat the above process to make a carbon fiber spring prefabricated body of the required size;

[0025] The surface density of the carbon fiber mesh tire of the present invention is 10g / m 2 ~100g / m 2 , needling density 10 times / cm 2 ~40 times / ㎝ 2 , needling depth 6㎜~25㎜, volume density of carbon fiber spring preform is 0.3g / ㎝ 3 ~0.6g / ㎝ 3 .

[0026] (2) Densification: The carbon fiber spring pr...

Embodiment 2

[0041] In order to further improve the coefficient of elasticity of the helical spring, after the step (2), the present invention prepares the carbon / carbon composite material spring body through impregnation-cracking or trichloromethylsilane chemical vapor deposition or reaction infiltration of silicon through the carbon / carbon composite spring body / Silicon carbide composite spring body, the volume density of carbon / carbon / silicon carbide composite spring body is 1.6g / ㎝ 3 ~2.6g / ㎝ 3 .

[0042] In this embodiment, after the carbon fiber spring preform is subjected to chemical vapor deposition, trichloromethylsilane chemical vapor deposition is carried out to prepare a carbon / carbon / silicon carbide composite material spring body, a carbon / carbon / silicon carbide composite material spring body The bulk density is 2.0g / ㎝ 3 .

[0043] The carbon-based composite helical spring prepared in this embodiment has an elastic constant of 3.0 kg / ㎜˜10 kg / ㎜.

[0044] The rest are the same...

Embodiment 3

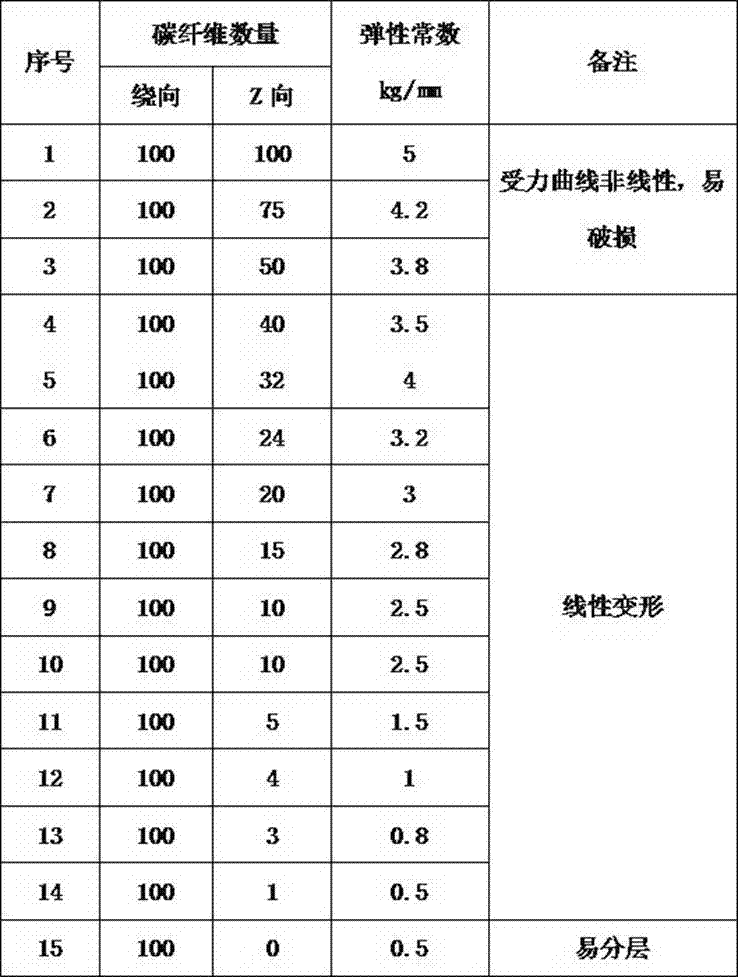

[0046] In order to introduce continuous long fibers in the axial direction of the helical spring, improve the axial resistance of the helical spring in the spring compression direction, and improve the deformation resistance of the helical reverse fiber, the present invention is in step (1) along the spiral of the spring on the mandrel. After winding the carbon fiber bundle or carbon fiber cloth with the width of the spring pitch in the wire direction, the carbon fiber mesh tire, carbon fiber cloth, and carbon fiber mesh tire are respectively wound on the mandrel one by one. The axial direction is consistent, and at the same time, each time the carbon fiber mesh tire is wound, needle punching is carried out along the radial direction of the mandrel to introduce Z-direction carbon fiber; repeat the above process to make a carbon fiber spring prefabricated body of the required size.

[0047] The surface density of the carbon fiber mesh tire of the present invention is 10g / m 2 ~1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com