Vertical and ring direction gum dipping wet process glass fiber reinforced plastic tubing continuous pipe twining machine

A fiberglass and hoop technology, which is applied in the field of production and molding equipment of glass steel pipes, can solve the problems of unidirectional glass fiber yarn impregnation and impermeability of impregnation, so as to improve mechanical properties, increase density and mechanical strength, and eliminate impregnation fault effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

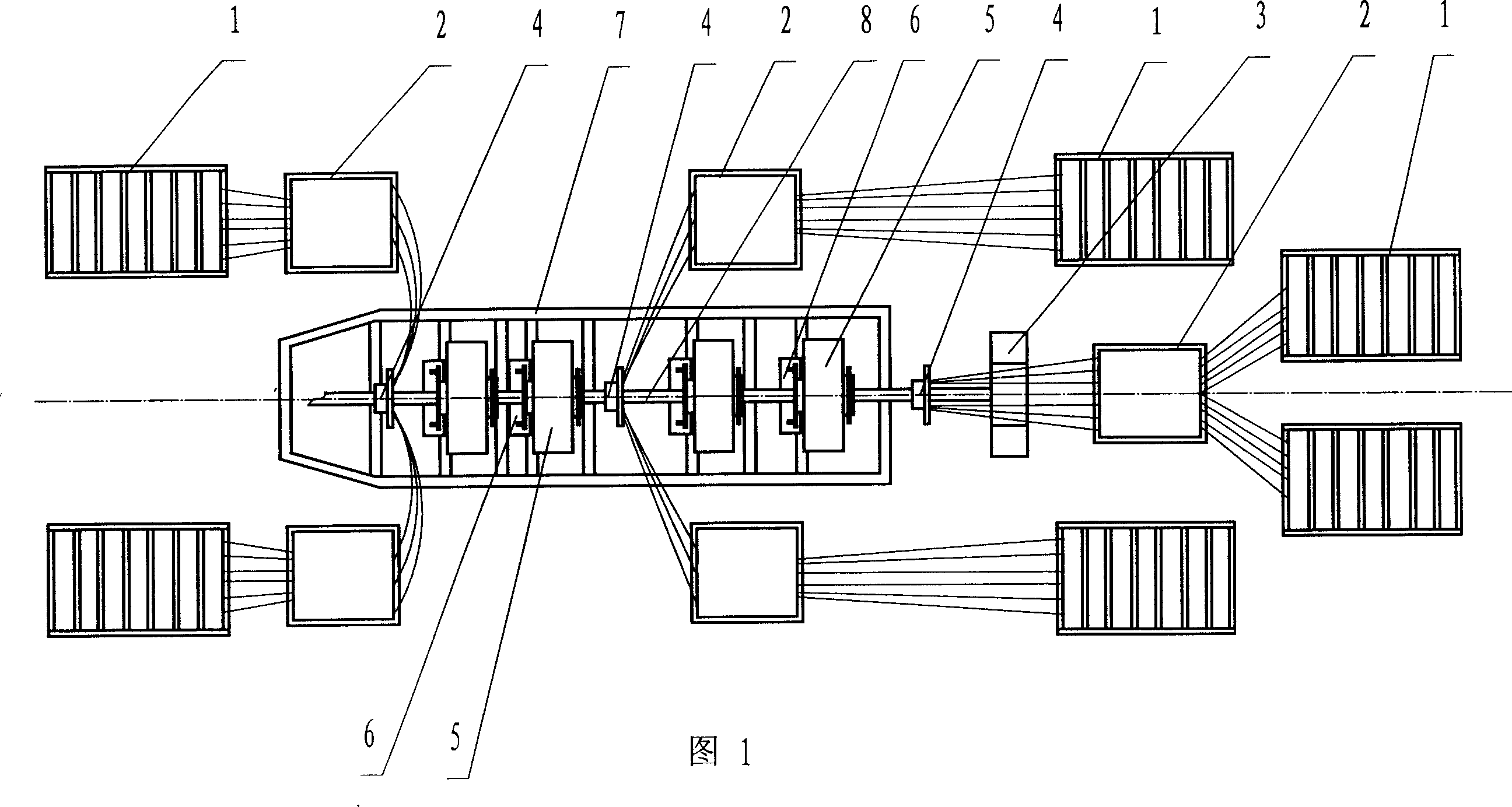

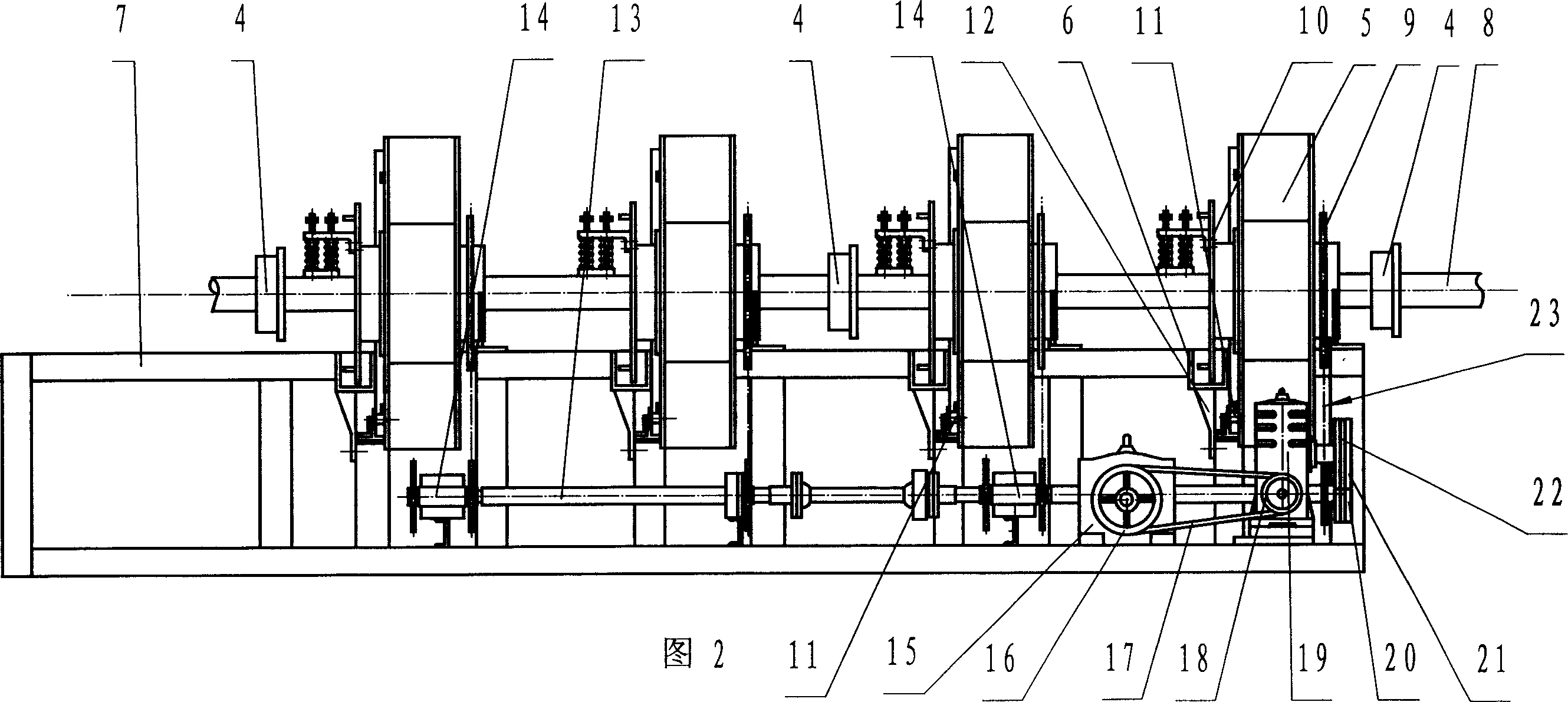

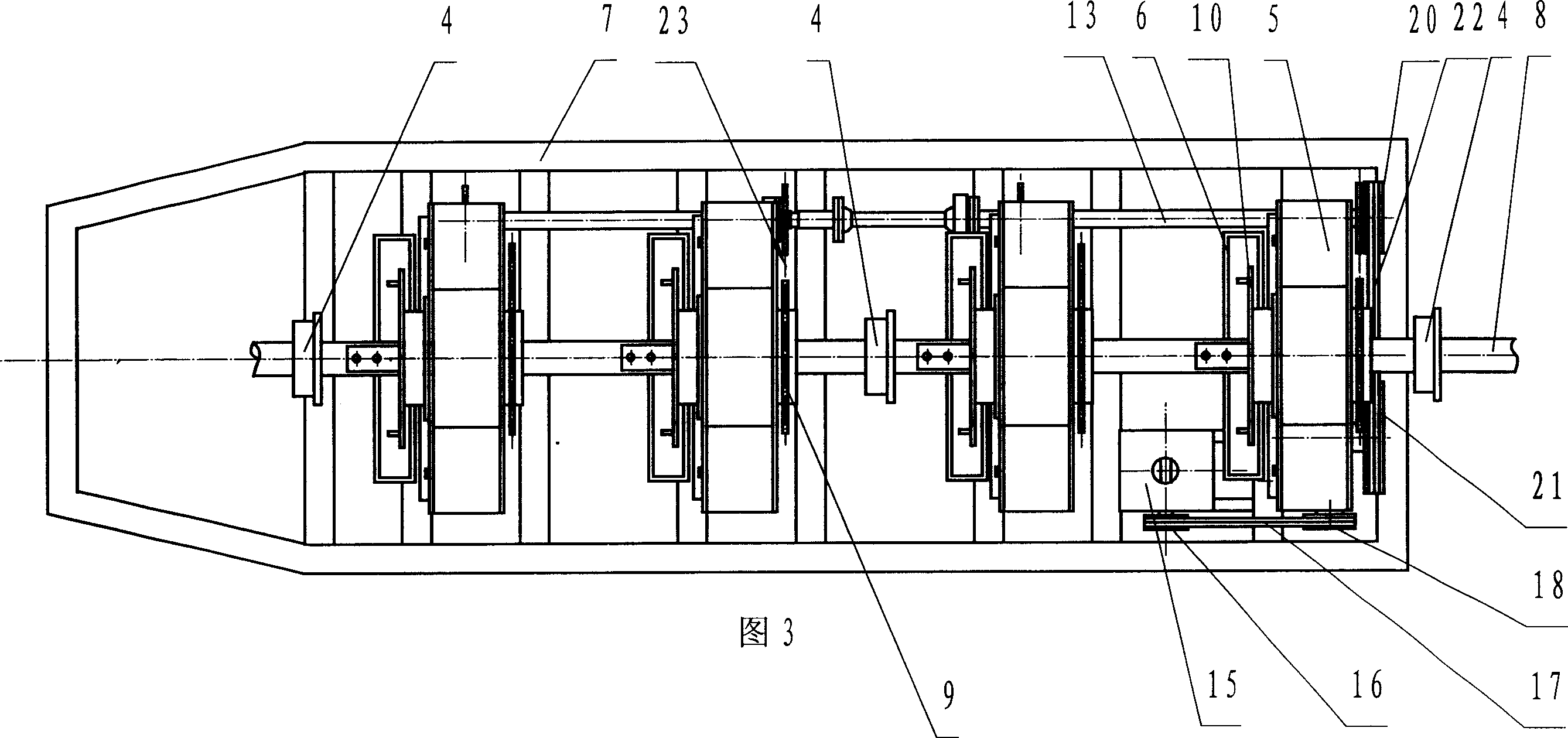

[0022]As shown in the drawings, the present invention includes a mandrel 8, a frame 7, a power transmission device, a longitudinal creel 1, a longitudinal yarn dipping tank 2 and a distributor 4. The mandrel 8 is a cantilever shaft fixed on the machine On the frame 3, the frame 3 is fixed on the foundation; a resistance heater is provided in the mandrel 8 to heat the wound glass steel pipe, and the power transmission device is installed on the frame 7; the longitudinal creel 1 and the longitudinal Yarn dipping tank 2 and distributor 4 have several groups, the present invention is three groups, and the first group is made up of two longitudinal creels 1, a longitudinal yarn dipping tank 2 and a distributor 4, the second group and the third The group consists of two longitudinal creels 1, two longitudinal yarn dipping tanks 2 and a distributor 4; the two longitudinal creels 1 of the first group are installed side by side behind the mandrel 8, and the two longitudinal creels 1 sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com