Production method of titanium dioxide particles

A titanium dioxide and production method technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, coating, etc., can solve the problems of slow promotion, high price, single color of pigment, etc., and achieve excellent near-infrared reflection ability, excellent weather resistance, The effect of excellent scattering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

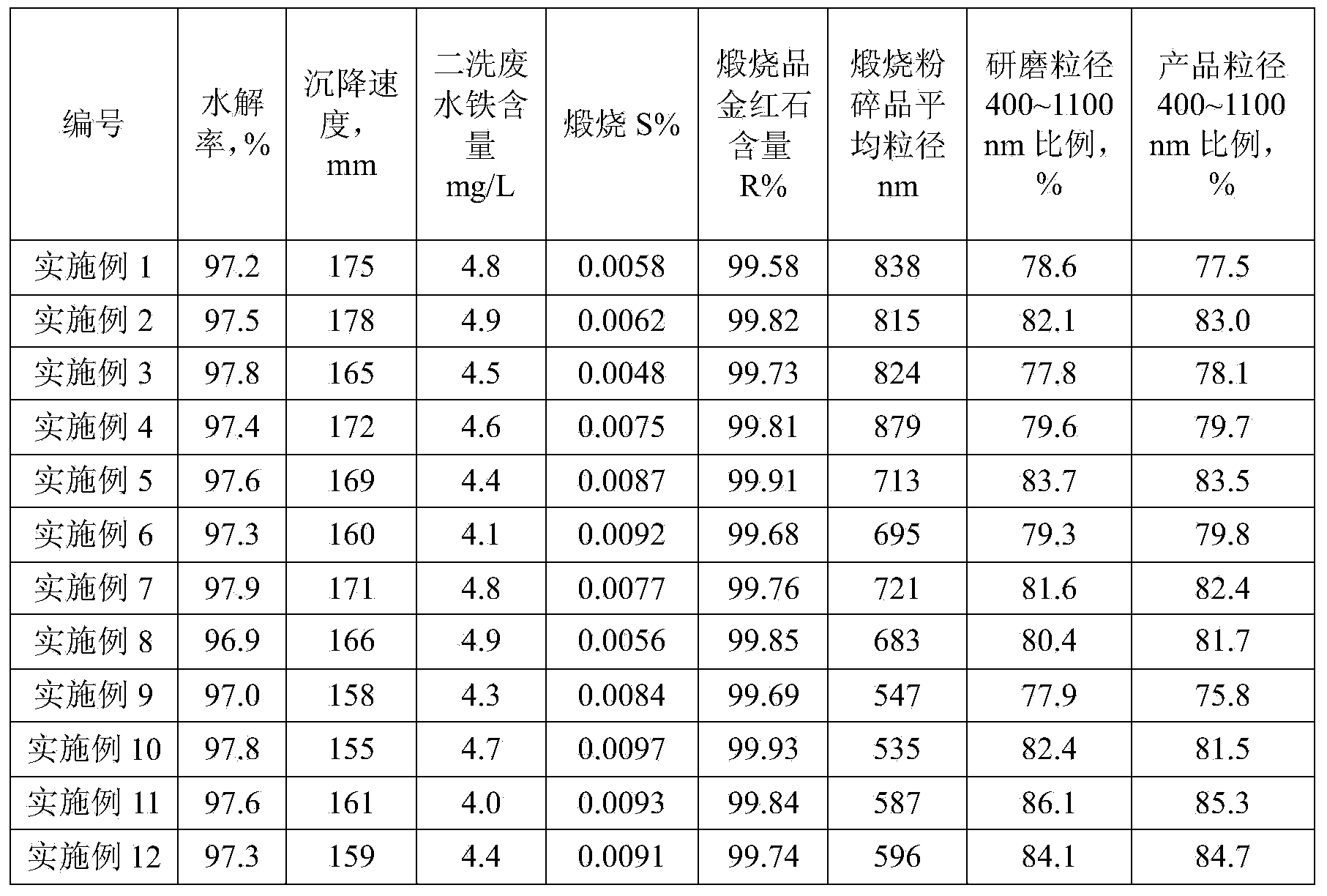

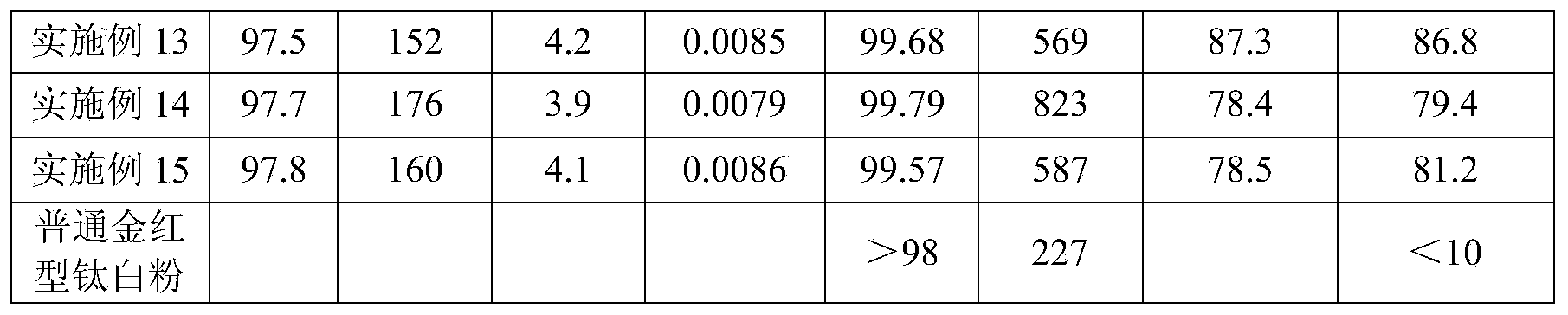

Examples

Embodiment 1

[0015] The index of the prepared titanium solution is: TiO 2 =160.5g / L; F-H 2 SO 4 =103.5g / L; Fe / TiO 2 =0.26, the seed crystal titanium solution is taken according to the proportion volume of 2.0% of the total volume of the hydrolyzed titanium solution, preheated to 80°C, and NaOH is used according to 15.1% of the total titanium content of the seed crystal titanium solution and preheated to 82°C, at 2 Add the preheated titanium solution into the preheated NaOH solution within 1 minute, then raise the temperature to 92°C, stop heating; take 10ml seed crystals to measure the stability, control the stability to 160ml, and the seed crystal preparation is completed; hydrolyze the titanium solution Raise the temperature to 90°C, add the prepared seed crystals, stir for 1 minute, raise the temperature to 102°C at a rate of 0.4-0.6°C / min, keep the temperature until the titanium liquid becomes slightly turbid and stop heating, and press 0.9°C when the temperature drops to 98°C ~1.1°...

Embodiment 2

[0017] The operation process is the same as in Example 1, except that the qualified metatitanic acid is prepared into a slurry with a concentration of 420g / L for salt treatment, and calcined seeds are added in a proportion of 1.5% for salt treatment, and hydrogen is added in a proportion of 0.2%. Potassium oxide, phosphoric acid is added at a rate of 0.15%, and aluminum sulfate is added at a rate of 0.4%. After stirring evenly, filter and dry and calcined, the maximum temperature of calcining is controlled at 1000±10°C.

Embodiment 3

[0019] Operation process is with embodiment 1. The difference is that 2.5% calcined seeds are added in the bleaching process, and the salt treatment is no longer added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com