High haze transparent conductive film and manufacturing method thereof

A technology of transparent conductive film and high haze, applied in the direction of conductive layer on insulating carrier, cable/conductor manufacturing, circuit, etc., can solve the problem of poor transmittance improvement effect, achieve strong adhesion, effective Good for storage and transportation, strong scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

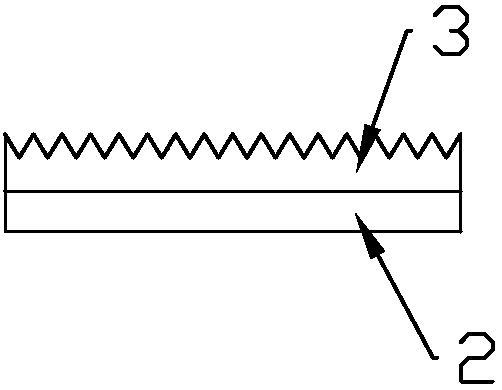

[0044] A silver grid transparent electrode with high haze random suede scattering, including a silver grid transparent electrode, one side of the silver grid transparent electrode is a smooth plane, and the other side is coated with ultraviolet glue with a random inverted pyramid structure .

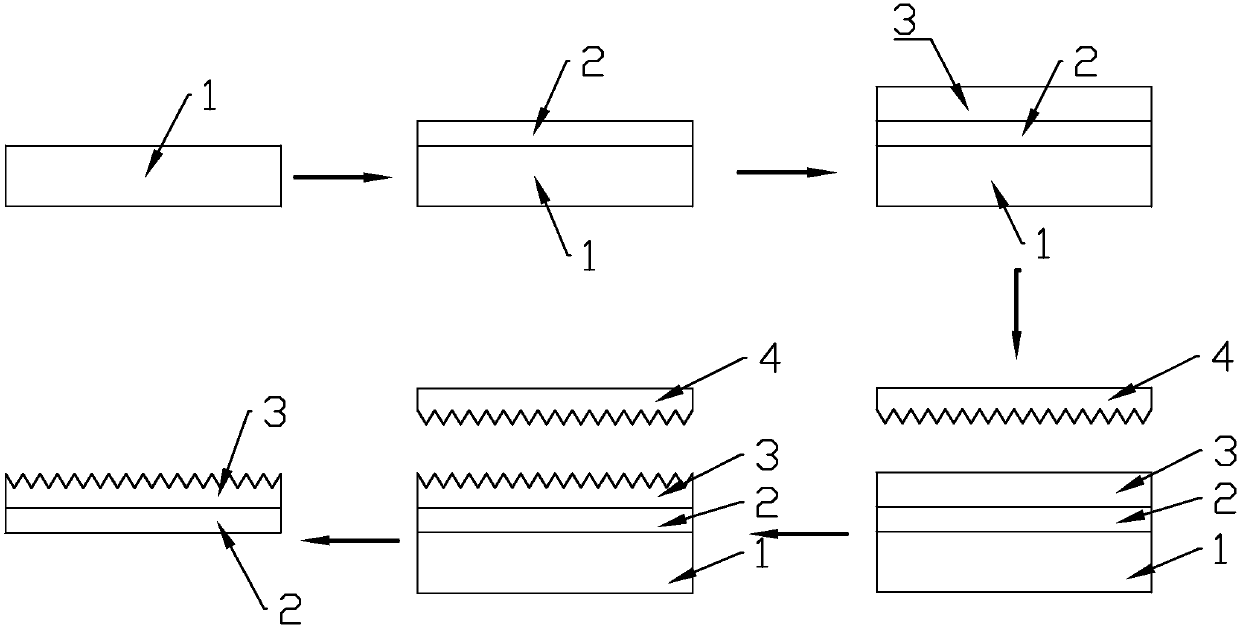

[0045] Such as figure 2 Shown, the preparation method of the transparent conductive film of above-mentioned high haze is as follows:

[0046] (1) preparing a layer of thickness on the silicon substrate as a 30nm silver grid transparent electrode;

[0047] (2) The method of spin coating is adopted to spin coat a layer of UV glue with a thickness of 300 μm on the surface of the silver grid transparent electrode, the rotating speed of spin coating is 400rpm, and the time of uniform glue is 60s;

[0048] (3) Lightly press the transparent PDMS template with a nanometer-sized random inverted pyramid structure into contact with UV glue, and irradiate it under a UV lamp for 1 min;

[0049] (4)...

Embodiment 2

[0063] An ultrathin metallic silver transparent electrode with high haze nanocone scattering, whose structure is as follows figure 1 As shown, it includes an ultra-thin silver transparent electrode, one side of the silver transparent electrode is a smooth plane, and the other side is coated with ultraviolet glue with a nanocone structure.

[0064] Such as figure 2 Shown, the preparation method of the transparent conductive film of above-mentioned high haze is as follows:

[0065] (1) preparing a layer of thickness on the silicon substrate as a 7nm ultra-thin silver transparent electrode;

[0066] (2) Adopting the method of spin coating, spin coating one deck thickness on the surface of silver transparent electrode is 500 μ m UV glue, the rotating speed of spin coating is 500rpm, and the time of uniform glue is 30s;

[0067] (3) Lightly press the transparent PDMS template with the nanocone structure into contact with the UV glue, and irradiate it under the UV lamp for 1 min;...

Embodiment 3

[0076] A silver nanowire transparent electrode with high haze random suede scattering, including a silver nanowire transparent electrode, one side of the silver nanowire transparent electrode is a smooth plane, and the other side is coated with ultraviolet glue with a random inverted pyramid structure .

[0077] Such as figure 2 Shown, the preparation method of the transparent conductive film of above-mentioned high haze is as follows:

[0078] (1) preparing a layer of thickness on the silicon substrate as a silver nanowire transparent electrode of 90nm;

[0079] (2) Adopt the method of spin-coating, on the surface of the transparent electrode of silver mesh, spin-coat a layer of thickness and be 1 μ m UV glue, the rotating speed of spin-coating is 8000rpm, and the time of uniform glue is 15s;

[0080] (3) Lightly press the transparent PDMS template with a nanometer-sized random inverted pyramid structure into contact with UV glue, and irradiate it under a UV lamp for 1 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com