Method for preparing formed selective catalytic reduction denitration catalyst by using ultrasonic mixing sedimentation method

A denitration catalyst and mixed precipitation technology are applied in the field of preparation of shaped selective catalytic reduction denitration catalysts, which can solve the problem that the structure of matrix and impregnating components cannot be closely combined, the influence of catalyst catalytic activity and thermal stability, catalyst specific surface area and porosity Low problems, to achieve the effect of excellent characterization characteristics, reasonable distribution of surface void structure, and reasonable particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

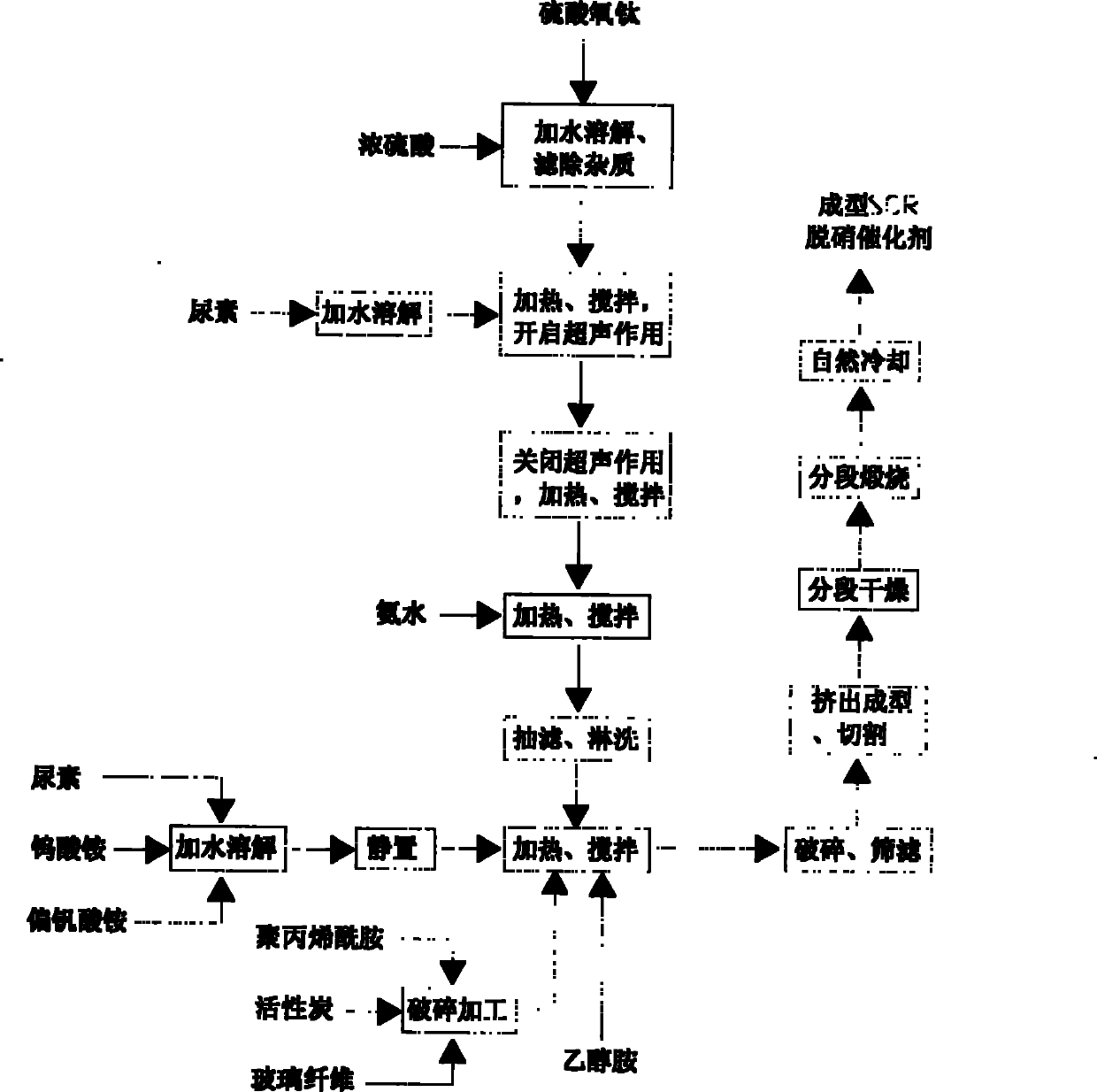

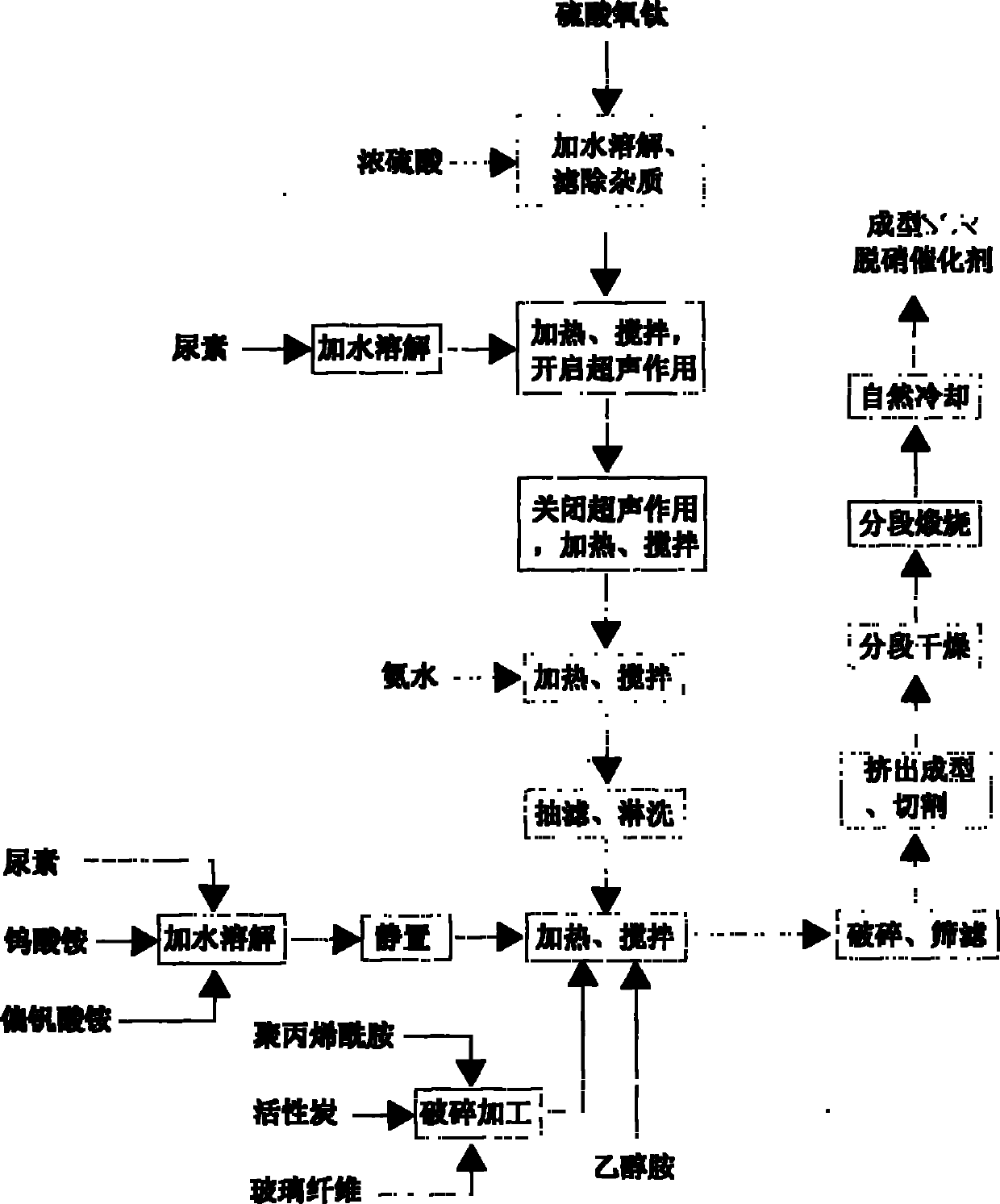

[0038] The preparation method of a novel molding SCR denitrification catalyst described in the present invention, the active ingredient type of the catalyst is V 2 o 5 -WO 3 / TiO 2 , taking the preparation process of honeycomb-shaped SCR denitration catalyst as an example, the preparation steps are as follows:

[0039] 1) Titanium oxysulfate (TiOSO 4 ) into water (the ratio of titanyl sulfate (pure) to water is controlled within the range of 10-15g: 100ml), stirring continuously to make it completely dissolved, and adding a small amount of concentrated sulfuric acid at the same time, adjusting the pH value of the solution to within the range of 0.6-1.5 (eg: 0.6, 0.8, 1.0, 1.2, 1.4, 1.5), and the solution is filtered to remove insoluble impurities therein.

[0040] 2) Dissolve urea in water to make a solution, wherein the ratio of water to urea (pure) (per 10g titanyl sulfate (pure)) is 8-10ml: 8g, and the solution prepared in step 1) is placed at 80 ℃~85℃ under constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com