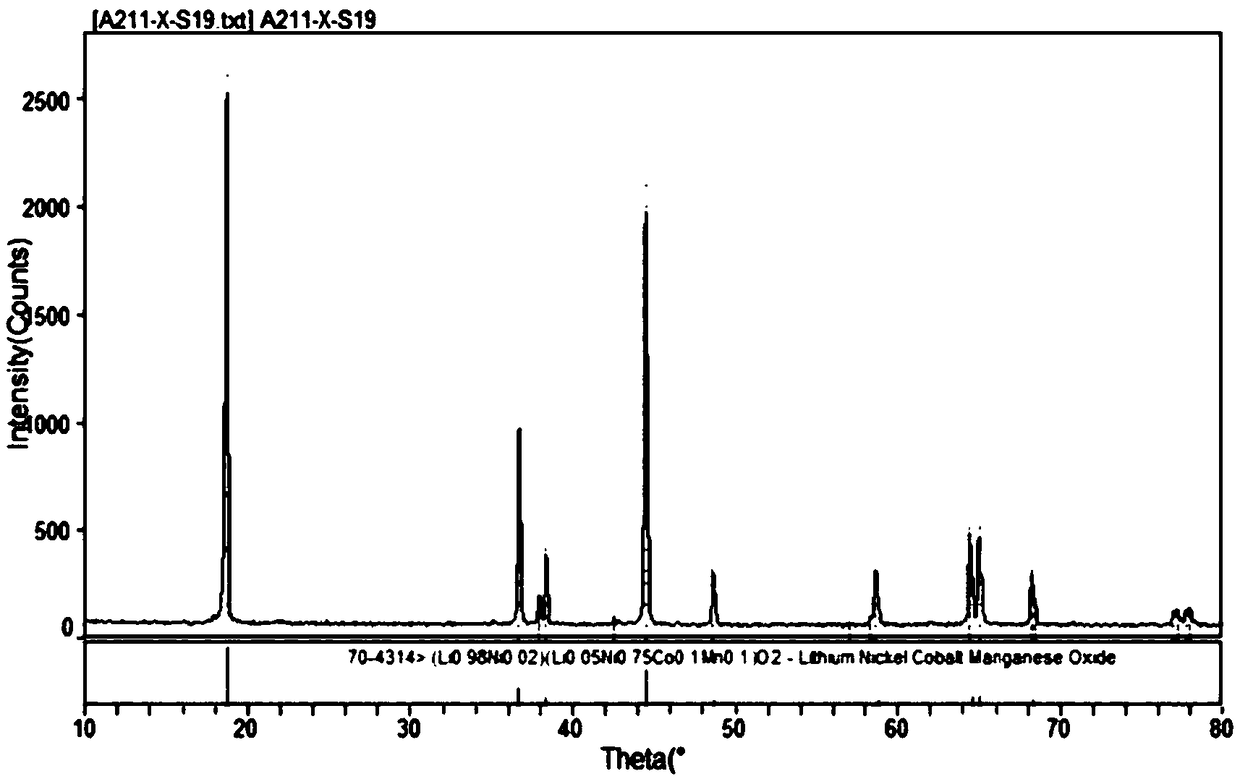

A high-pressure monocrystalline nickel-cobalt-manganese ternary material and a preparation method thereof

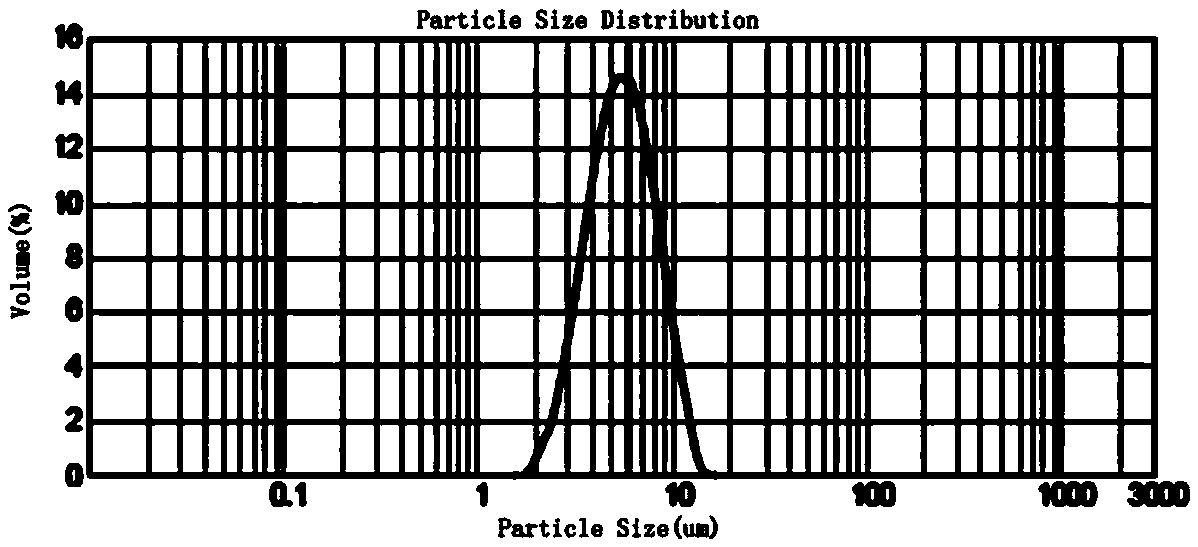

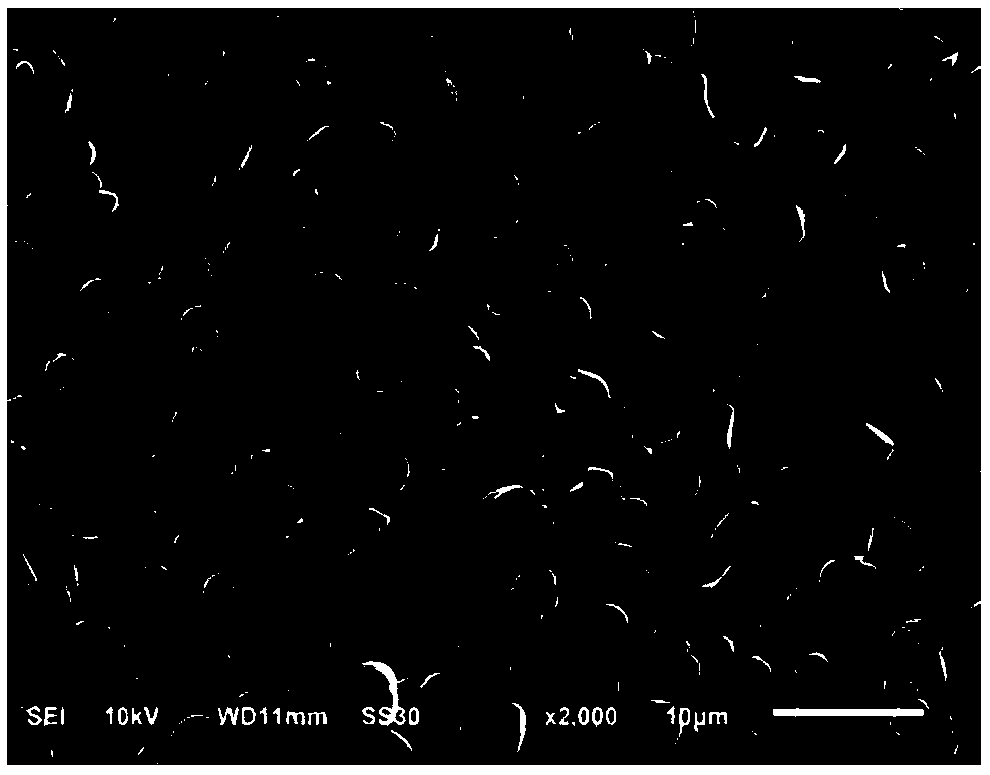

A ternary material, nickel-cobalt-manganese technology, applied in the direction of electrode manufacturing, electrical components, electrode heat treatment, etc., can solve the problems of high production cost, complicated process, poor performance, etc., and achieve low corrosion, uniform particle size distribution, and optimized cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a high-pressure compacted single crystal nickel-cobalt-manganese ternary material, which comprises the steps of:

[0038] (1) Preparation of Ni by co-precipitation method 1-x-y co x mn y (OH) 2 Precursor;

[0039] Wherein: 0

[0040] Co-precipitation method is to use nickel-cobalt-manganese salts to co-precipitate in the solution to prepare the precursor. Ternary materials with various shapes such as shell structure, spherical shape, and nanoflowers, and relatively uniform particle size distribution, thus effectively ensuring the shape of the precursor of the ternary material and improving the compaction density.

[0041] Preferably, the described adopt coprecipitation method to prepare Ni 1-x-y co x mn y (OH) 2 The precursor includes the following steps:

[...

Embodiment 1

[0078] Preparation:

[0079] (1) Mix nickel sulfate, cobalt sulfate and manganese sulfate uniformly according to the molar ratio of Ni:Co:Mn=0.5:0.25:0.25 to obtain 1 mol / L solution A. Weigh sodium hydroxide and add deionized water to prepare a 5 mol / L solution B; weigh 20% concentrated ammonia water to prepare a 3.6 mol / L solution C.

[0080](2) Weigh 300g, 500g, and 100g of the above solution A, solution B, and solution C respectively, add 1000g of pure water to the reactor, add solution A, solution B, and solution C to the reactor at the same time, and the stirring rate of the reactor Controlled at 600rpm. The reaction process needs to be fed with nitrogen for protection, the flow rate is 13L / min, the reaction temperature is kept at 50°C, the pH is kept at 8.5-10.5, and the reaction time is 45h.

[0081] (3) After the reaction is completed, the slurry is suction filtered, washed and dried to obtain a precursor.

[0082] (4) Weigh 1500 g of lithium carbonate and the precu...

Embodiment 2

[0088] Preparation:

[0089] (1) Mix nickel sulfate, cobalt sulfate, and manganese sulfate uniformly according to the molar ratio of Ni:Co:Mn=0.5:0.2:0.3 to obtain a solution A of 1.8 mol / L. Weigh sodium hydroxide and add deionized water to prepare a 5 mol / L solution B; weigh 20% concentrated ammonia water to prepare a 3.8 mol / L solution C.

[0090] (2) Weigh 350g, 550g, and 100g of the above-mentioned solution A, solution B, and solution C respectively, add 1500g of pure water to the reactor, add solution A, solution B, and solution C to the reactor at the same time, and the stirring rate of the reactor Controlled at 700rpm. The reaction process needs to be fed with nitrogen for protection, the flow rate is 20L / min, the reaction temperature is kept at 60°C, the pH is kept at 9-11, and the reaction time is 48h.

[0091] (3) After the reaction is completed, the slurry is suction filtered, washed and dried to obtain a precursor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com