Carbon raw material crushing screening method and system

A technology of crushing and screening raw materials, which is applied in the field of raw material crushing and screening methods and systems for the production of aluminum anodes, cathodes and electrodes. Load and other problems, to avoid overload, the effect of reasonable particle size distribution of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

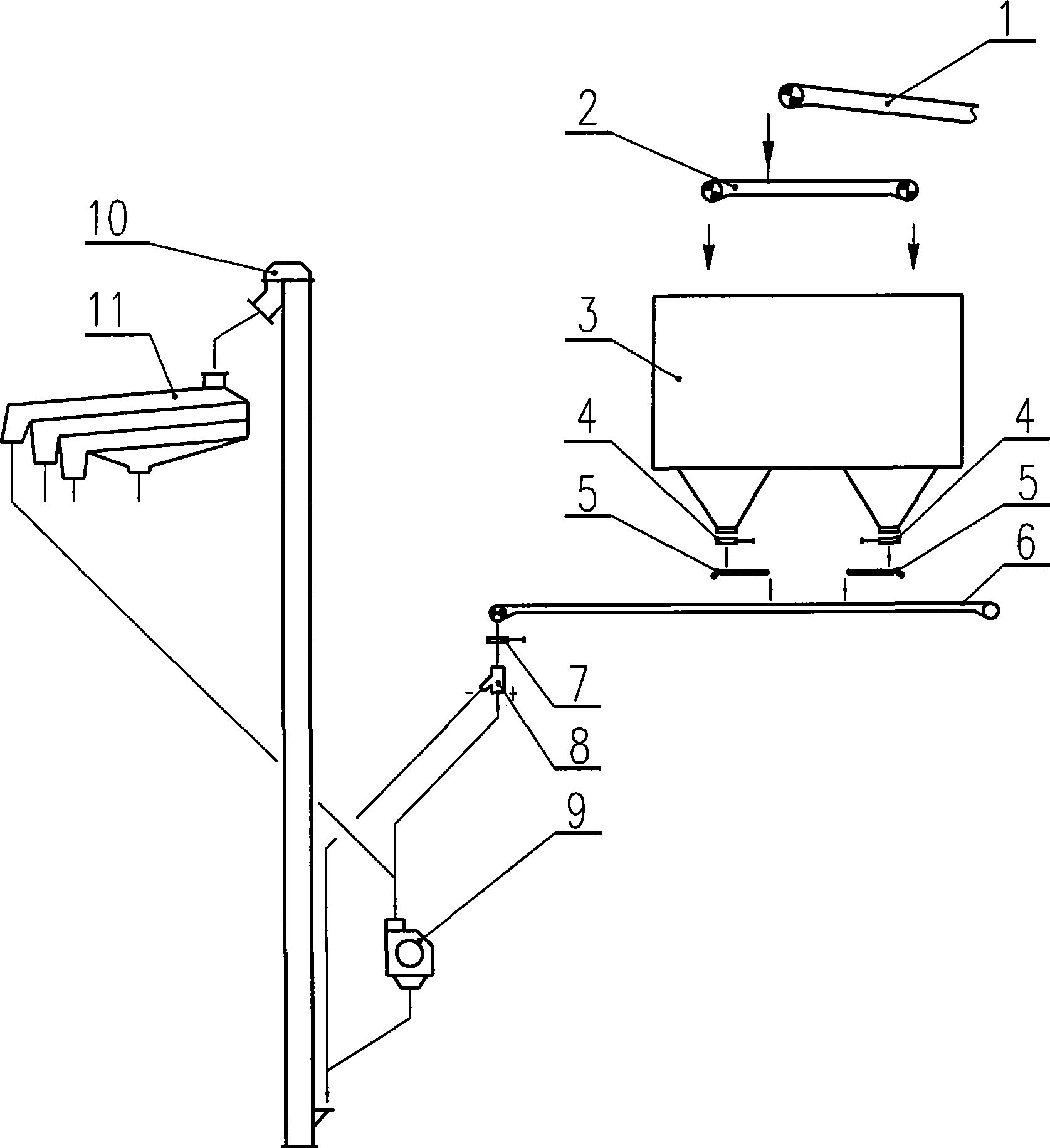

[0030] The carbonaceous raw material crushing and screening method of the present invention comprises the steps of: sending the raw material to the belt conveyor 6, the belt conveyor 6 receives the raw material from the raw material storage bin 3, and the raw material storage bin 3 first sends the raw material to the feed machine 5, and then sent to the belt conveyor 6, the raw material storage bin 3 receives the raw materials conveyed by the reversible belt conveyor 2, and the reversible belt conveyor 2 receives the raw materials conveyed by the first belt conveyor 1, and passes through the belt conveyor The online sampling analyzer 7 at the end of the machine 6 analyzes and controls the three-way valve 8 to discharge materials according to the particle size of the raw materials. The three-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screen aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com