Method for preparing YAG-based transparent ceramics under Mg aid system

A technology of transparent ceramics and sintering aids, which is applied in the field of advanced ceramic preparation and can solve undeveloped problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

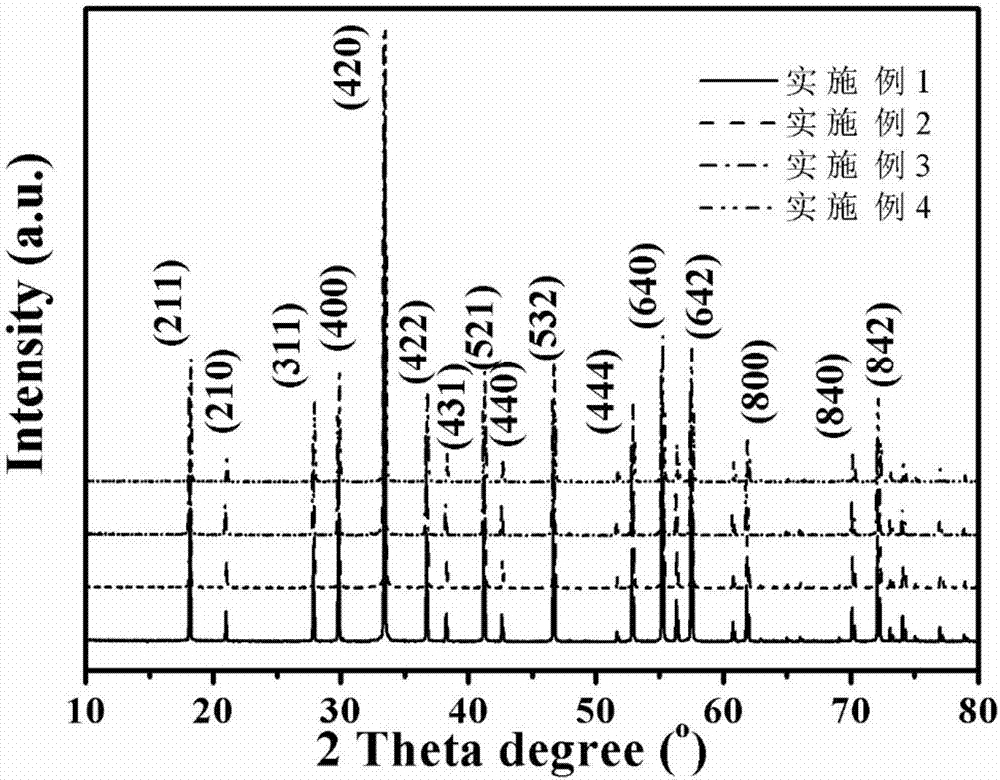

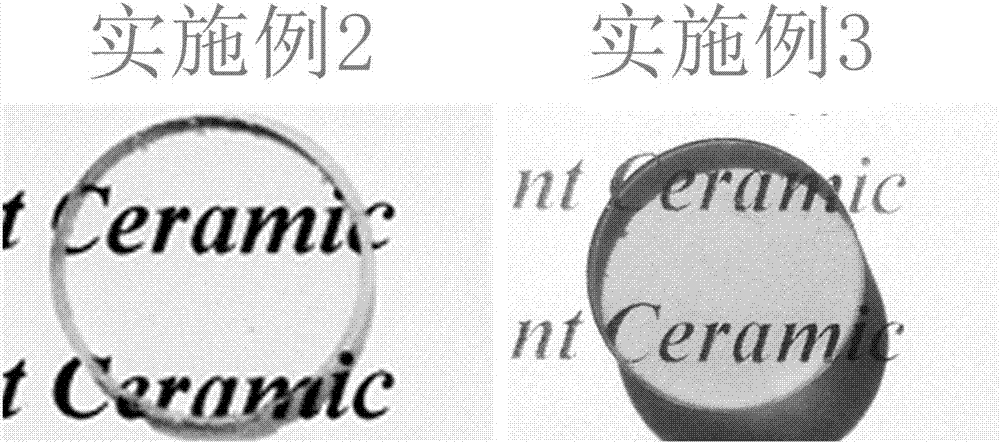

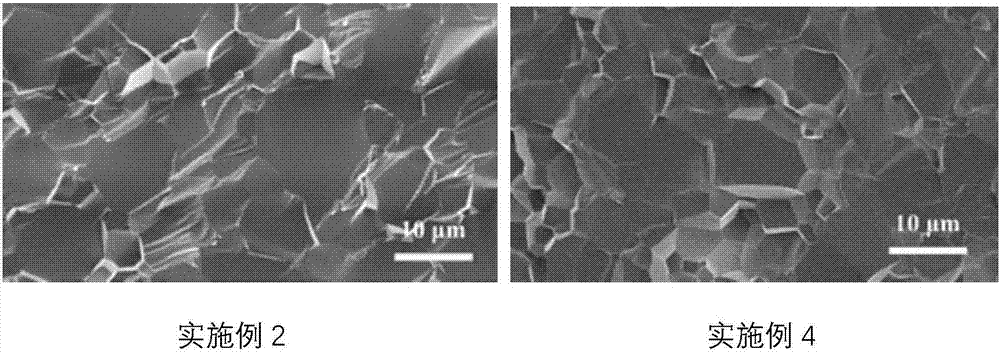

[0030] The present invention provides a kind of under non-annealing mechanism, adopts the vacuum sintering under the single additive system of a small amount of Mg to prepare yttrium aluminum garnet (Y 3 al 5 o 12 , YAG)-based transparent ceramics, characterized in that a small amount of Mg is used as a single sintering aid, and a single-step vacuum sintering method is used to prepare YAG transparent ceramics with good optical quality without post-annealing treatment. The transparent ceramic components should satisfy the following formula (1) or formula (2):

[0031] (Re x Y 1-x ) 3 al 5 o 12 (1)

[0032] Y 3 (Cr y al 1-y ) 5 o 12 (2)

[0033] In the formula, the value range of x is 0≤x≤0.6, the range of y is 0≤y≤0.05, Re is one of Ce, Nd, Yb, Er, Ho, Dy, Pr, Tm, Sm, Eu or Tb . The amount of Mg added is 0.003-0.018wt.% of the total mass of Y, Al, Cr or Y, Al, Re raw material powder. The line transmittance at 1064nm of the finally prepared YAG transparent cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com