Rotor type powder concentrator

A technology of powder separator and rotor type, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., which can solve the problems of reduced powder selection efficiency, reduced powder selection efficiency, and short service life of rotors, etc. problems, to achieve the effect of increased cement strength, reasonable particle size distribution, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention aims to provide a solution to achieve the purposes of improving powder selection efficiency, reducing over-grinding, making product particle size distribution more reasonable, and reducing system power consumption.

[0027] In order to achieve the above objective, the present invention adopts the following technical solutions.

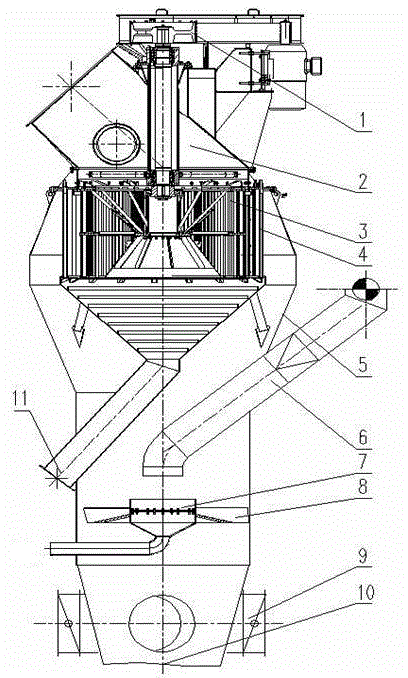

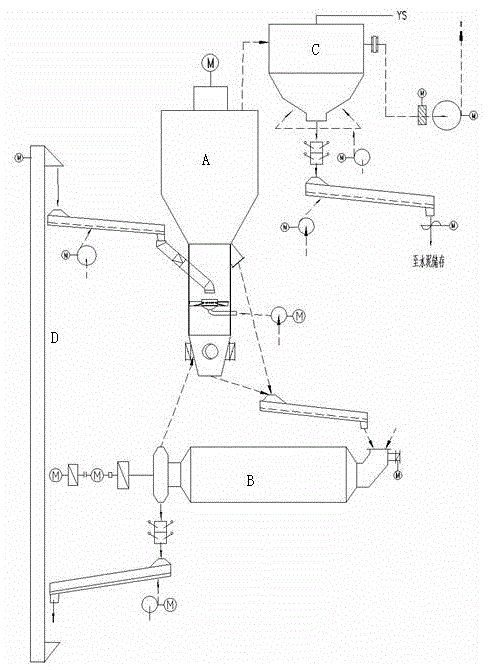

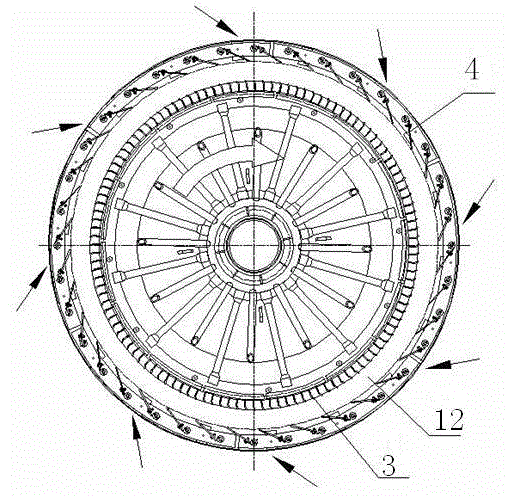

[0028] The high-efficiency rotor-type powder separator of the present invention includes a material dispersion device, a blowing device, an air compensation device, a rotor separation system, etc. The rotor separation system includes a sorting air chamber, a guide vane structure as a stator blade, and a rotor. After the airflow and materials are evenly mixed through the material dispersing device and the spraying device, they enter the stationary blade in the same rotation direction as the stationary blade. The material can be separated into coarse and fine particles in the sorting air chamber. Preferably, the guide blade struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com