Whole-process low-nitrogen combustion technology applied to cement kiln for reduction of cement kiln NOx discharge quantity

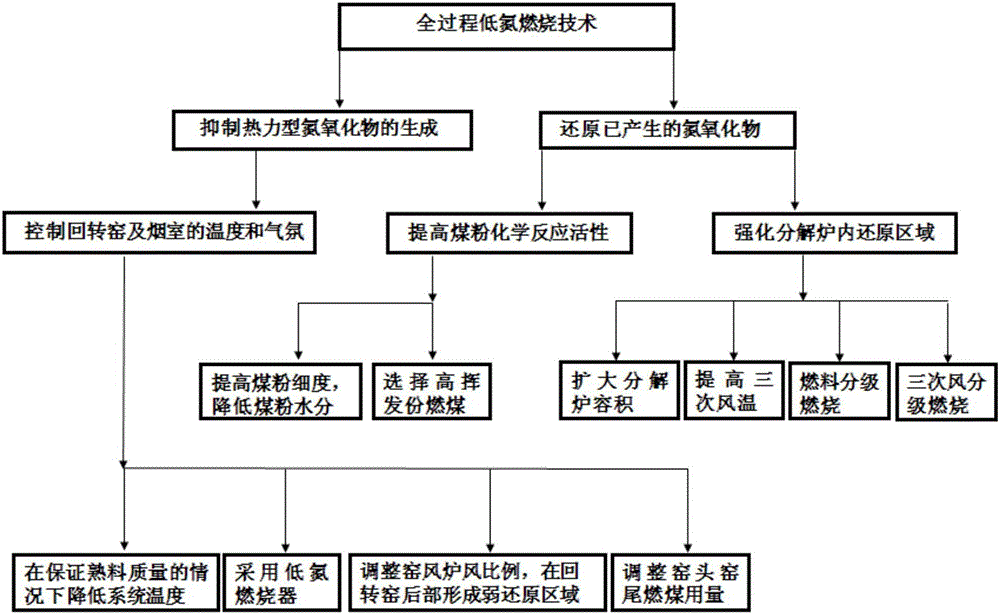

A cement kiln, low-nitrogen combustion technology, applied in combustion methods, combustion equipment, furnaces, etc., can solve problems such as the inability to effectively reduce nitrogen oxide emissions, and achieve the effects of reducing denitration costs, reducing environmental pollution, and reducing heat consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

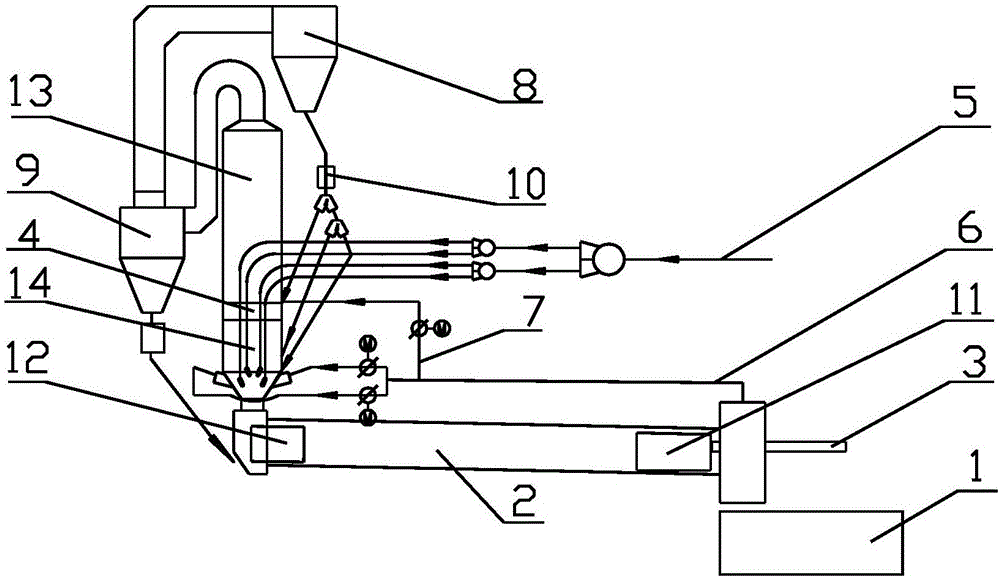

[0052] A 2500t / d cement production line in Inner Mongolia, the rotary kiln is φ4×60m, the calciner is an online pipeline calciner, and the furnace capacity is 584m 3 , The NOx emission concentration of the chimney at the kiln tail reaches 720-750ppm during operation (when the SNCR is not operating), and the whole process of low-nitrogen combustion technology has been adopted for the transformation of the plant. The feed rate remains unchanged at 180t / h, bituminous coal is used, the coal consumption of the calciner is increased from 9.3t / h to 9.7t / h, the coal consumption of the kiln head is reduced from 5.5t / h to 5.1t / h, and the high-temperature fan speed Decrease from 725r / min to 705r / min, adjust the tertiary air pipe and its gate valve of the air distribution pipe to control the oxygen content in the calciner at about 0.5%, the excess air coefficient in the rotary kiln is less than 1.0, and increase the cone of the calciner by 2 low The coal feeding amount of the nitrogen bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com