Method for preparing lithium iron phosphate with dynamic sintering method and sintering device thereof

A lithium iron phosphate and sintering device technology, which is applied to chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve the problems of small particles of lithium iron phosphate products, insufficient contact of sintering raw material particles, uneven mixing, etc. , to achieve the conditions of improving reaction thermodynamics and kinetics, easy discharge of gas products, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

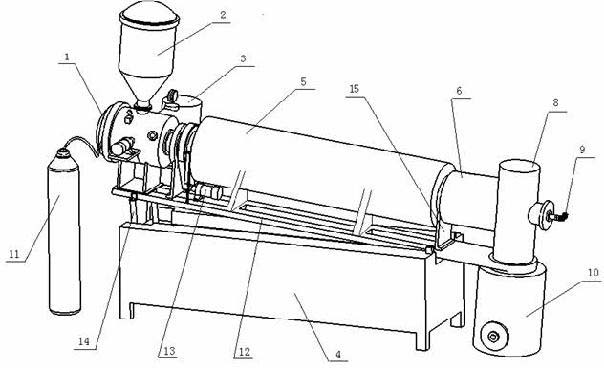

[0040] see figure 1 , the present invention utilizes dynamic sintering method to prepare the method for ferrous phosphate lithium adopts the method that " one-step carbothermal reduction " and dynamic sintering combine, and the sintering device of the present invention is key equipment. The sintering device of the present invention includes a fixed frame 4, including a feeding device arranged on the fixed frame 4, a sintering kiln 5, a discharge valve 6 and a product discharge device, and also includes a reaction atmosphere control execution device, a sintering kiln 5 It is a double-layer structure shell, the inner layer is a shielded sintered inner hearth furnace, the outer layer is a heating layer, the sintered inner hearth furnace is equipped with a feeding device, and one side of the sintered inner hearth furnace is provided with a raw material input port. And it is sealed and connected with the discharge port of the feeding device. The other end of the sintering inner hea...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

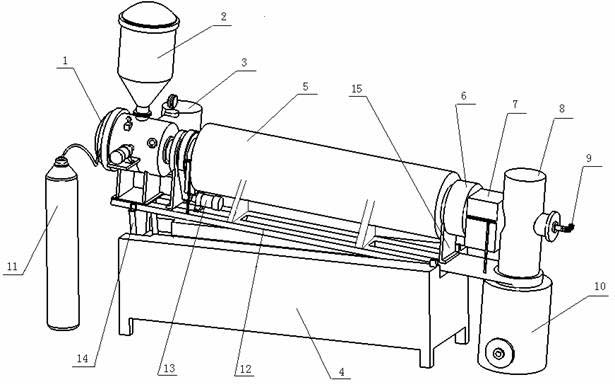

[0047] see figure 2 , there is also a water cooler 7 between the discharge valve 6 and the vacuum receiver 8, the cavity of the water cooler 7 forms a delivery channel, the front end of the delivery channel communicates with the discharge valve 6, and the end of the delivery channel It communicates with the receiver 8.

[0048] With lithium carbonate (Li 2 CO 3 ), iron oxide (Fe 2 o 3 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) as the main raw material without doping ions, polypropylene powder is used as the carbon source, and the carbon source is added according to the amount of 31.6g per mole of lithium ferrous phosphate. Put the main raw materials into a wet ball mill and use ethanol as the medium for ball milling for 2 hours, add polypropylene powder and grind for another half an hour, take it out for later use. Put the ground raw materials into a hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com