Raw-glaze novel microcrystalline tactile sensation-imitation thick glaze-polished brick and production method thereof

A technology of polished glazed tiles and thick glazed tiles, which is applied in the field of ceramic tiles, and can solve the problems that microcrystalline tiles cannot have a three-dimensional and moist feeling at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

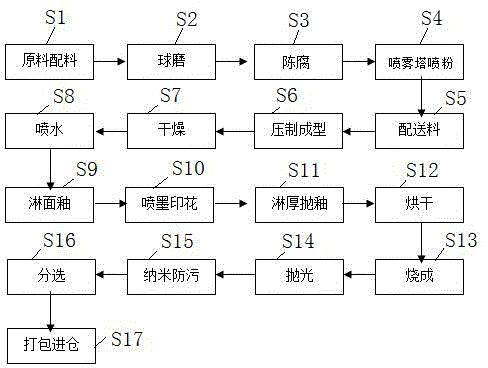

[0035] like figure 1 Shown is a flow chart of the steps of a novel glazed tile with thick glaze and a preparation method thereof. A novel glazed tile with thick glaze as described above and a preparation method thereof, the specific steps are as follows:

[0036] S1. Raw material ingredients. The batching is configured according to the above-mentioned green body formula, and the charge enters the ball mill.

[0037] S2, ball milling. Through ball milling, the fineness of the mud can meet the process requirements. Among them, the ball milling process parameters are: slurry moisture: 33%-37%, slurry flow rate: 30-70s, slurry fineness: 0.8-1.0g / 250 mesh sieve, powder moisture: 6.7%-7.2 %, powder gradation: 20 mesh ≤ 1%, 40% ≤ 40 mesh ≤ 48%, 100 mesh ≤ 4.5%.

[0038] S3, stale. After pulping, sieving, and iron removal, it is put into the mud pool to be stirred and stale for later use

[0039] S4, spraying tower spraying powder. The stale mud is spray-dried through the spra...

Embodiment 1

[0057] In terms of mass percentage, ball clay: 5.02%, raw mud: 18.05%, medium temperature sand: 32.10%, terrazzo powder: 21.06%, feldspar: 20.06%, high alumina sand: 2.01%, talc: 1.71% and weighing ingredients , as a body formula for a new type of glazed tile with thick glaze. According to the formula of the green body, the ingredients are fed into the ball mill. The technological parameters of the green body are: slurry moisture: 33% ~ 37%, slurry flow rate: 30 ~ 70s, slurry fineness: 0.8 ~ 1.0g / 250 mesh sieve residue, powder Moisture content: 6.7% to 7.2%. The ball milled mud that reaches the fineness required by the process is put into the mud pool to be stirred and stale after being discharged, screened, and iron removed. The stale mud is spray-dried through a spray drying tower to obtain powder. The powder gradation: 20 mesh upper ≤ 1%, 40% ≤ 40 mesh upper ≤ 48%, 100 mesh lower ≤ 4.5%, and enters the homogenization silo. After the homogenization silo is stale, the powder...

Embodiment 2

[0061]In terms of mass percentage, ball clay: 5.02%, raw mud: 18.05%, medium temperature sand: 32.10%, terrazzo powder: 21.06%, feldspar: 20.06%, high alumina sand: 2.01%, talc: 1.71% and weighing ingredients , as a body formula for a new type of glazed tile with thick glaze. According to the formula of the green body, the ingredients are fed into the ball mill. The technological parameters of the green body are: slurry moisture: 33% ~ 37%, slurry flow rate: 30 ~ 70s, slurry fineness: 0.8 ~ 1.0g / 250 mesh sieve residue, powder Moisture content: 6.7% to 7.2%. The ball milled mud that reaches the fineness required by the process is put into the mud pool to be stirred and stale after being discharged, screened, and iron removed. The stale mud is spray-dried through a spray drying tower to obtain powder. The powder gradation: 20 mesh upper ≤ 1%, 40% ≤ 40 mesh upper ≤ 48%, 100 mesh lower ≤ 4.5%, and enters the homogenization silo. After the homogenization silo is stale, the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com