Manganese-based low-temperature denitration catalyst taking TiO2-SiO2 as carrier and preparation method thereof

A low-temperature denitration and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poisoning, catalyst activity deactivation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

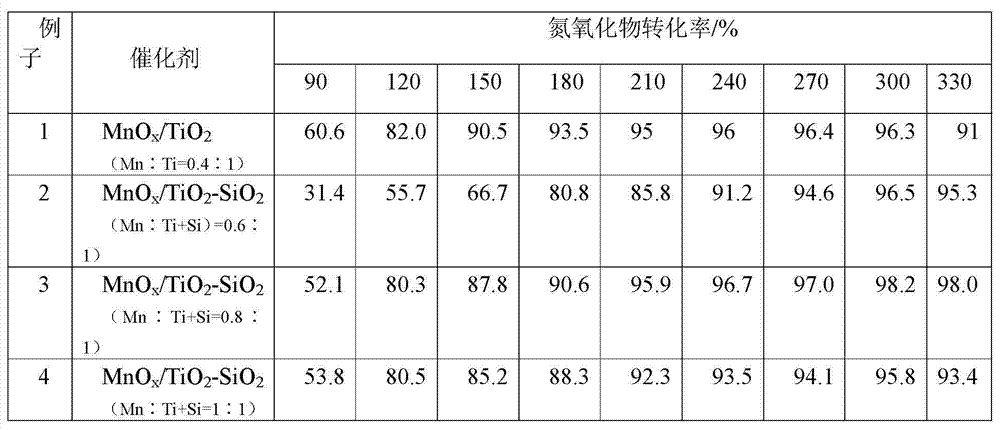

Examples

Embodiment 1

[0018] A TiO 2 The preparation of the supported manganese-based denitration catalyst (mass ratio Mn:Ti=0.4:1) includes the following steps

[0019] In the first step, 6ml of anhydrous acetic acid was added to 68g of tetrabutyl titanate, stirred by magnetic force for 10 minutes, and recorded as solution A.

[0020] In the second step, solution A was added dropwise to 220ml of absolute ethanol, stirred for 25 minutes, and finally recorded as solution B.

[0021] In the third step, add 28.6g of 50% (mass percentage concentration) manganese nitrate solution into 110ml of absolute ethanol, then add 18ml of deionized water, stir for 20 minutes, and record it as C solution.

[0022] In the fourth step, the C solution in the third step is added dropwise to the B solution, put into a water bath at 40°C and stirred until a gel is formed.

[0023] Step 5: Take the formed gel out of the water bath, age at room temperature for 20 hours, pour it into an evaporating dish, put it in a vacuu...

Embodiment 2

[0025] A TiO 2 -SiO 2 The preparation of manganese-based denitration catalyst (Mn:(Ti+Si)=0.6:1) as a composite support includes the following steps

[0026] In the first step, add 3ml of anhydrous acetic acid to 34g of ethyl orthosilicate, magnetically stir for 10 minutes, and record it as solution A; add 3ml of anhydrous acetic acid to 27g of tetrabutyl titanate, and magnetically stir for 10 minutes , recorded as solution B.

[0027] In the second step, solution A is added dropwise to 220ml of absolute ethanol, and after stirring for 25 minutes, solution B is added dropwise, and after stirring for 25 minutes, it is recorded as solution C.

[0028] In the third step, add 49.4g of 50% (mass percentage concentration) manganese nitrate solution into 110ml of absolute ethanol, then add 7ml of deionized water, stir for 20 minutes, and record it as D solution.

[0029] In the fourth step, add the D solution in the third step to the C solution dropwise, put it in a water bath at ...

Embodiment 3

[0032] A TiO 2 -SiO 2 The preparation of manganese-based denitration catalyst (Mn:(Ti+Si)=0.8:1) as a composite support includes the following steps

[0033] In the first step, add 3ml of anhydrous acetic acid to 34g of ethyl orthosilicate, magnetically stir for 10 minutes, and record it as solution A; add 3ml of anhydrous acetic acid to 27g of tetrabutyl titanate, and magnetically stir for 10 minutes , recorded as solution B.

[0034] In the second step, solution A is added dropwise to 220ml of absolute ethanol, and after stirring for 25 minutes, solution B is added dropwise, and after stirring for 25 minutes, it is recorded as solution C.

[0035] In the third step, add 65.2g of 50% (mass percentage concentration) manganese nitrate solution into 110ml of absolute ethanol, stir for 20 minutes, and record it as D solution.

[0036] In the fourth step, add the D solution in the third step to the C solution dropwise, put it in a water bath at 40°C and stir until a gel is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com