A kind of preparation method of high thermal stability feldspar ceramic blank and product thereof

A high thermal stability, feldspar-based technology, applied to clay products, other household utensils, household utensils, etc., can solve problems that affect product performance and pass rate, increase expansion coefficient, and large internal stress of porcelain body, etc., to achieve favorable Industrial promotion and application, improvement of strength and toughness, and effect of meeting light transmittance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

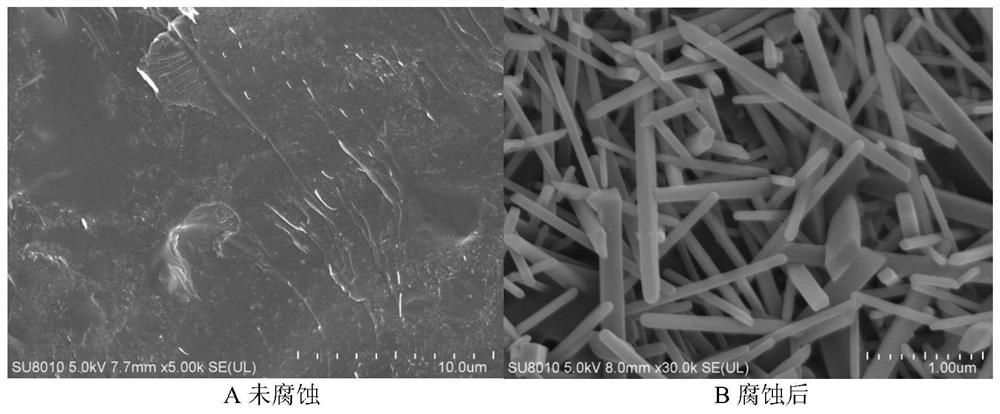

Image

Examples

Embodiment Construction

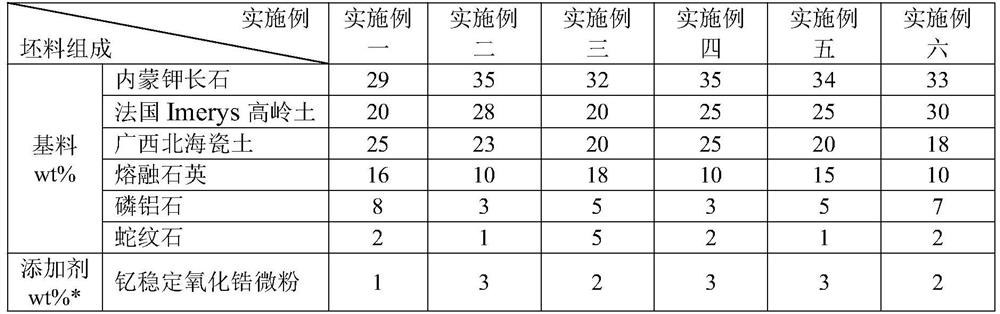

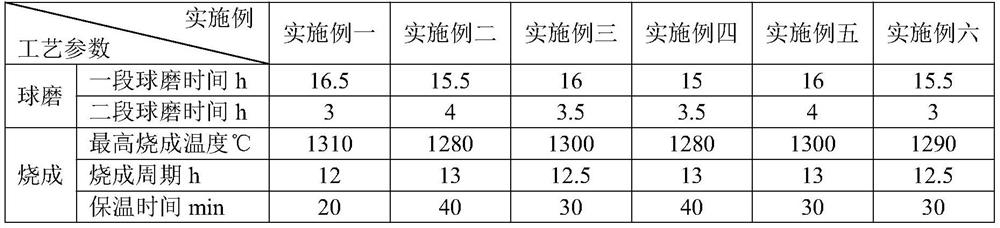

[0021] An embodiment of the present invention is a high thermal stability feldspathic ceramic blank, including a base material and additives; wherein, the base material is composed of Inner Mongolia potassium feldspar 25-35 wt%, French Imerys kaolin 20-35 wt%, Guangxi Beihai porcelain clay 18-35 wt%. 25wt%, fused silica 10-20wt%, phosphate dynamite 3-8wt%, serpentine 1-5wt%; the additive is yttrium-stabilized zirconia micropowder with yttrium content of 8moL% (fineness 1-5μm, D90≤5μm ), its consumption is 1~3%wt of base material.

[0022] Among them, the chemical compositions of Inner Mongolia potassium feldspar, French Imerys kaolin, and Guangxi Beihai china clay are shown in Table 1.

[0023] Table 1 The chemical composition (wt %) of Inner Mongolia potassium feldspar, French Imerys kaolin, Guangxi Beihai china clay in the embodiment of the present invention

[0024] name K 2 o

Na 2 o

MgO CaO al 2 o 3

SiO 2

Fe 2 o 3

TiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com