Polished brick and its preparation method

A technology of polishing bricks and sedimentation mud, which is applied in the field of building materials, can solve the problems of narrow firing range, foaming of green bodies, irregular deformation, etc., and achieve the effects of reducing waste of mineral resources, reducing emissions, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

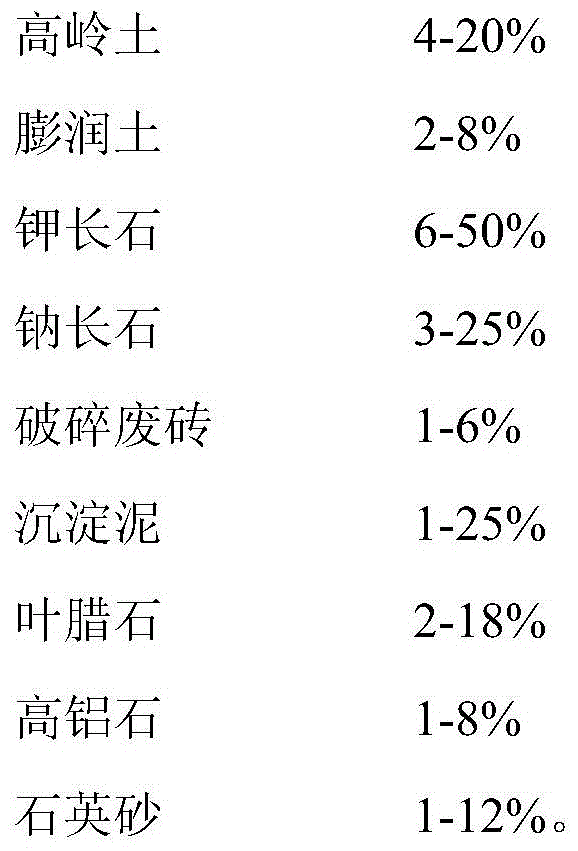

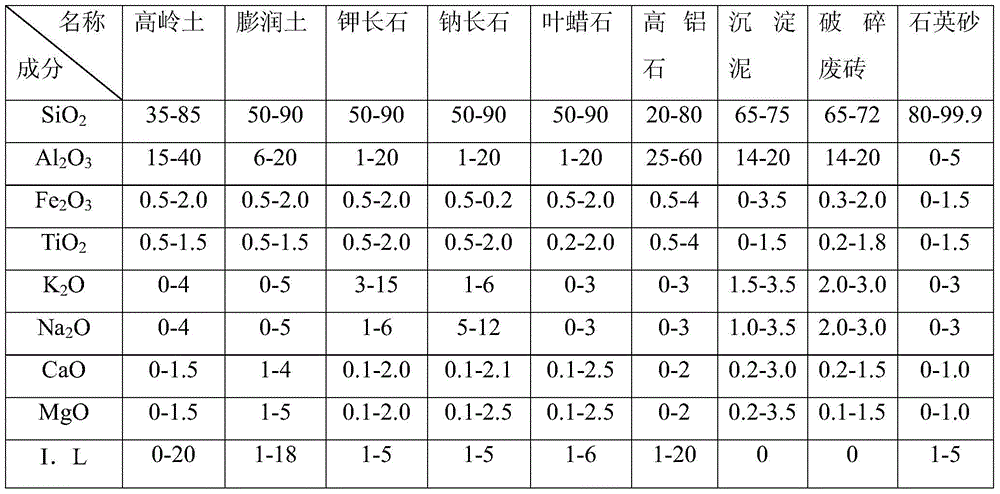

Method used

Image

Examples

Embodiment 1

[0037] The total mass of raw materials is 10kg, and the composition of raw materials is as follows:

[0038]

[0039] The preparation method is as follows:

[0040] (1) Press filter to make mud

[0041] The wastewater in the polishing circulating water tank is precipitated and filtered to obtain sedimentation mud, the moisture content of the sedimentary mud is 30%, and the filtered clean water is returned to the polishing circulating water tank;

[0042] (2) ball mill

[0043] Add kaolin, bentonite, potassium feldspar, albite, broken waste brick, sedimentary mud, pyrophyllite, high alumina, quartz sand and water into the ball mill for grinding, and the grinding time is 8h;

[0044] (3) Milling and pressing

[0045] The powder to be pressed is made by spray drying tower and pressed;

[0046] (4) Firing

[0047] After pressing, it is dried and fired in a firing kiln, the firing temperature is 1162 °C, and the firing time is 40 minutes to obtain semi-finished bricks;

[...

Embodiment 2

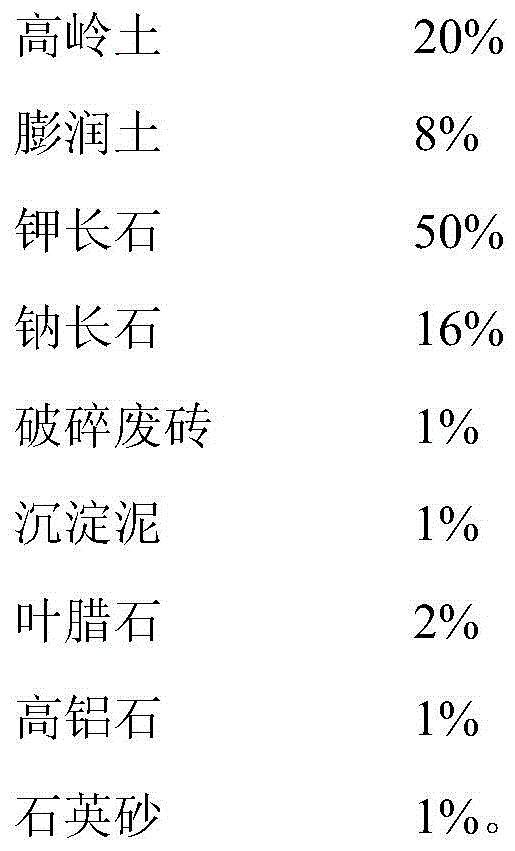

[0053] The total mass of raw materials is 10kg, and the composition of raw materials is as follows:

[0054]

[0055] The preparation method is as follows:

[0056] (1) Press filter to make mud

[0057] The wastewater in the polishing circulating water tank is precipitated and filtered to obtain sedimentation mud, the moisture content of the sedimentary mud is 25%, and the filtered clean water is returned to the polishing circulating water tank;

[0058] (2) ball mill

[0059] Add kaolin, bentonite, potassium feldspar, albite, broken waste brick, sedimentary mud, pyrophyllite, high alumina, quartz sand and water into the ball mill for grinding, and the grinding time is 13h;

[0060] (3) Milling and pressing

[0061] The powder to be pressed is made by spray drying tower and pressed;

[0062] (4) Firing

[0063] After pressing, it is dried and fired in a firing kiln, the firing temperature is 1158°C, and the firing time is 32 minutes to obtain semi-finished bricks;

[...

Embodiment 3

[0069] The total mass of raw materials is 10kg, and the composition of raw materials is as follows:

[0070]

[0071] The preparation method is as follows:

[0072] (1) Press filter to make mud

[0073] The wastewater in the polishing circulating water tank is precipitated and filtered to obtain sedimentation mud, the moisture content of the sedimentary mud is 35%, and the filtered clean water is returned to the polishing circulating water tank;

[0074] (2) ball mill

[0075] Add kaolin, bentonite, potassium feldspar, albite, broken waste brick, sedimentary mud, pyrophyllite, high alumina, quartz sand and water into the ball mill for grinding, and the grinding time is 10h;

[0076] (3) Milling and pressing

[0077] The powder to be pressed is made by spray drying tower and pressed;

[0078] (4) Firing

[0079] After pressing, it is dried in a firing kiln and fired at a firing temperature of 1175°C and a firing time of 35 minutes to obtain semi-finished bricks;

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com